Yes, a crucible is the essential tool for melting gold. It is the standard container used by jewelers, refiners, and metallurgists, specifically designed to withstand the extreme temperatures required to liquefy the metal. However, simply having a crucible is not enough; success and safety depend entirely on using the right type of crucible with the correct heat source and adhering to a strict, methodical process.

The core challenge is not if you can use a crucible, but how you manage the intense heat and inherent dangers of molten metal. The right crucible, proper heating technique, and an unwavering commitment to safety are the three pillars of successfully melting gold.

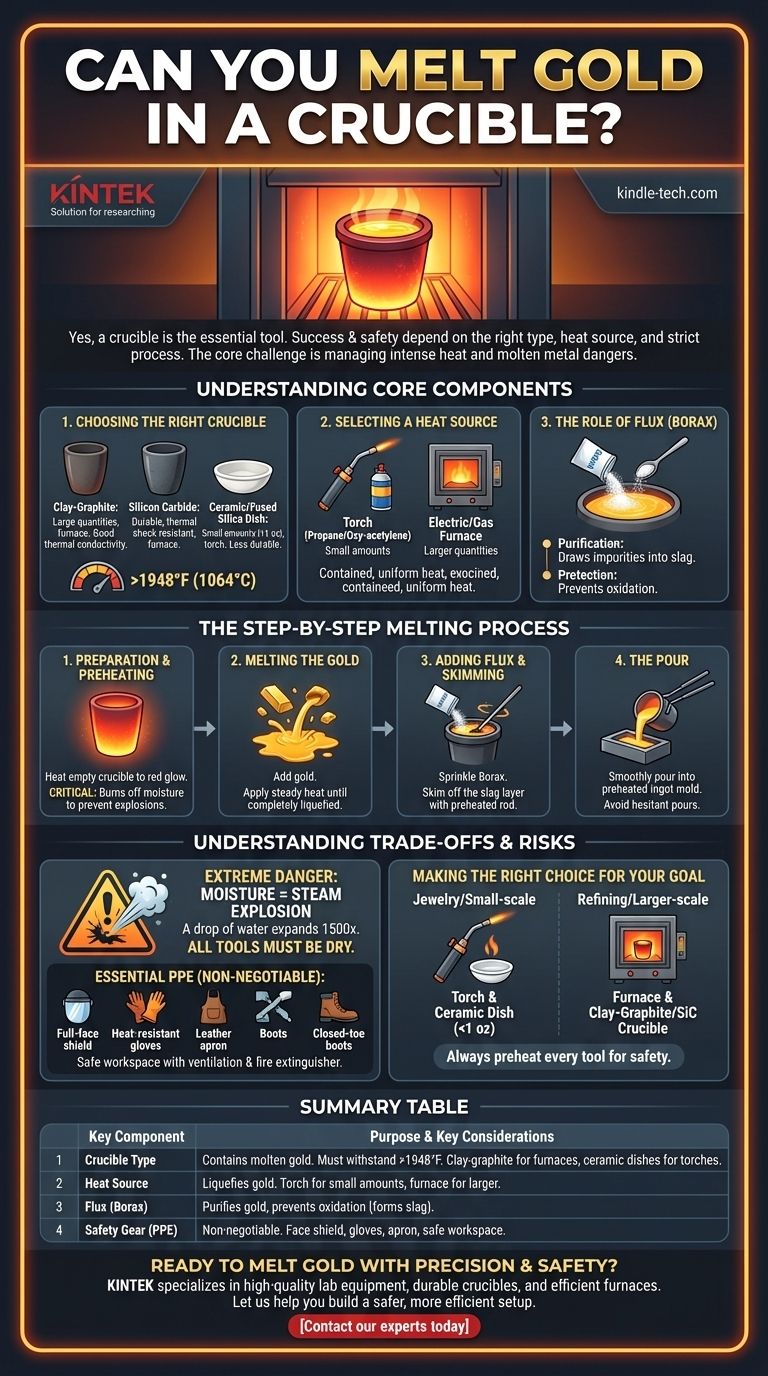

Understanding the Core Components

To melt gold effectively, you need three key elements: the right container (crucible), an adequate heat source, and a purifying agent (flux). Each plays a critical role in the final outcome.

Choosing the Right Crucible

The material of your crucible must be chosen based on your heat source and the amount of gold you are melting. Gold's melting point is approximately 1948°F (1064°C), so your crucible must handle temperatures well above this.

- Clay-Graphite Crucibles: These are the workhorses for melting larger quantities of gold in a furnace. The graphite provides excellent thermal conductivity for even heating, while the clay provides structural strength.

- Silicon Carbide Crucibles: Extremely durable and resistant to thermal shock, these are a premium choice for frequent, heavy-duty melting in gas or electric furnaces.

- Ceramic or Fused Silica Dishes: Often called "melting dishes," these are ideal for melting small amounts of gold (a few ounces or less) with a hand-held torch. They are less durable but perfect for small-scale jewelry work.

Selecting a Heat Source

Your heat source must be capable of delivering sustained, intense heat.

- Torch: A propane or oxy-acetylene torch is suitable for small amounts in a ceramic dish. The key is to apply heat evenly to avoid cracking the dish.

- Electric or Gas Furnace: For anything more than a few ounces, a dedicated melting furnace is necessary. These provide contained, uniform heat that is both safer and more efficient for melting the entire contents of a larger clay-graphite or silicon carbide crucible.

The Role of Flux

Flux, most commonly borax, is a critical addition. When sprinkled onto the molten gold, it serves two purposes:

- Purification: It draws out impurities from the gold, which congeal into a glassy layer called "slag" on the surface. This slag can then be skimmed off.

- Protection: It forms a protective barrier over the molten gold, preventing it from oxidizing when exposed to air.

The Step-by-Step Melting Process

A disciplined procedure is non-negotiable for safety and a quality result. Every tool that will touch the molten gold—including the ingot mold and stirring rod—must be preheated to be completely dry and to reduce thermal shock.

Step 1: Preparation and Preheating

Place the empty crucible into your furnace or onto a fireproof brick (if using a torch). Slowly heat the crucible until it glows red. This critical step burns off any residual moisture, which could otherwise cause a catastrophic steam explosion.

Step 2: Melting the Gold

Once the crucible is hot, carefully add your gold pieces. Apply steady, even heat until the gold completely liquefies into a bright, glowing liquid.

Step 3: Adding Flux and Skimming

Sprinkle a small pinch of borax onto the surface of the molten gold. You will see it dissolve and form a layer of slag. Use a preheated quartz or graphite rod to stir the metal gently and skim the slag off the top.

Step 4: The Pour

Using specialized crucible tongs, grasp the crucible firmly. In one smooth, confident motion, pour the molten gold into a preheated ingot mold. A hesitant pour can cause the gold to cool and solidify mid-stream, ruining the process.

Understanding the Trade-offs and Risks

Melting gold is an inherently dangerous activity. Understanding and mitigating the risks is the most important part of the process.

The Extreme Danger of Moisture

The single greatest danger is a steam explosion. If even a tiny drop of water or moisture comes into contact with molten gold, it will instantly flash into steam and expand to over 1,500 times its original volume. This causes a violent eruption, spraying molten metal everywhere. All tools, crucibles, molds, and even the gold itself must be perfectly dry.

Essential Personal Protective Equipment (PPE)

Never attempt to melt gold without proper safety gear. This is not optional.

- Full-face shield and safety glasses.

- Heat-resistant (Kevlar or leather) gloves.

- Leather apron or fire-resistant jacket.

- Closed-toe leather boots.

Creating a Safe Workspace

Your work area must be purpose-built for safety. It should have a non-flammable floor (like concrete), excellent ventilation to remove fumes, and no flammable materials nearby. A Class D fire extinguisher should always be within reach.

Making the Right Choice for Your Goal

Your approach should be tailored to the scale of your work and your primary objective.

- If your primary focus is jewelry making or small-scale hobby work: A torch and a small ceramic melting dish are a cost-effective and practical setup for amounts under an ounce.

- If your primary focus is refining larger quantities or casting objects: A dedicated electric furnace paired with a durable clay-graphite or silicon carbide crucible is the only reliable and safe option.

- If your primary focus is safety (as it always should be): Always preheat every tool and vessel to a dull red glow to guarantee it is bone-dry before it ever contacts molten metal.

By respecting the materials, the heat, and the process, you can achieve your goal safely and effectively.

Summary Table:

| Key Component | Purpose & Key Considerations |

|---|---|

| Crucible Type | Contains molten gold. Must withstand >1948°F (1064°C). Clay-graphite for furnaces, ceramic dishes for torches. |

| Heat Source | Liquefies the gold. Torch for small amounts (<1 oz), furnace for larger quantities. |

| Flux (Borax) | Purifies gold and prevents oxidation by forming a protective slag layer. |

| Safety Gear (PPE) | Non-negotiable. Includes face shield, heat-resistant gloves, apron, and safe workspace. |

Ready to melt gold with precision and safety?

Whether you're a jeweler creating new pieces or a refiner processing material, having the right, reliable equipment is the foundation of success. KINTEK specializes in high-quality lab equipment, including durable crucibles and efficient melting furnaces, designed to meet the exacting demands of laboratory and workshop environments.

Let us help you build a safer, more efficient setup. Contact our experts today to find the perfect crucible and heating solution for your specific gold melting needs.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- High Purity Pure Graphite Crucible for Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What is a magnetron sputtering? A Guide to High-Quality Thin-Film Deposition

- How does a magnetron sputtering work? A Guide to High-Quality Thin Film Deposition

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What are the disadvantages of DC magnetron sputtering? Key Limitations for Your Lab

- What is the fundamental of magnetron sputtering? Master High-Quality Thin Film Deposition