In short, yes. You absolutely need a protective sheet when using a heat press, and silicone-coated paper is an excellent option for this. Its primary purpose is to act as a non-stick barrier, protecting both your heat press platen from residue and your garment from direct, potentially scorching heat. However, it is one of several professional options available.

The core principle is not about using a specific brand or type of paper, but about consistently using a non-stick, heat-resistant protective sheet. This simple step is the dividing line between amateur mistakes and professional, repeatable results, safeguarding your equipment and your products.

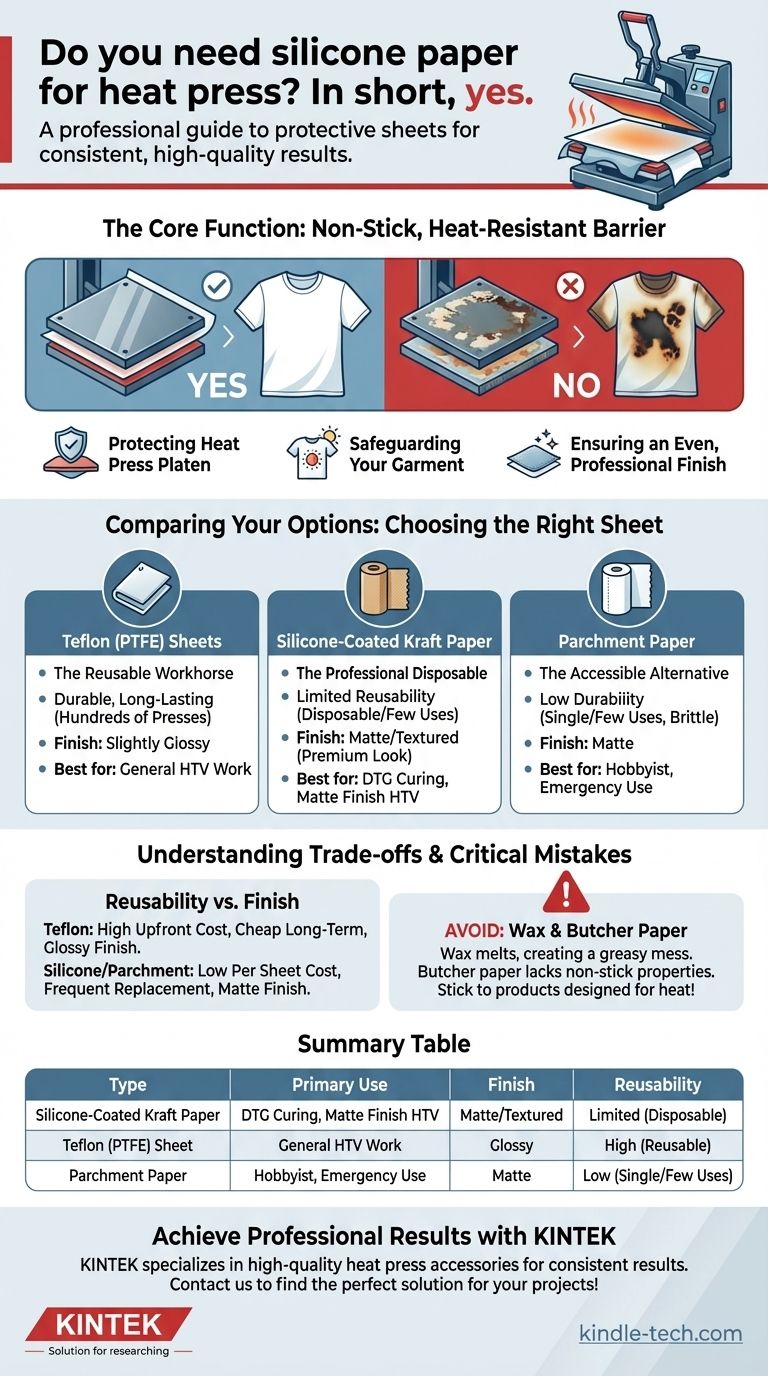

The Core Function of a Protective Sheet

Using a heat press without a protective sheet is a significant risk. These sheets perform three critical functions that ensure the quality of your work and the longevity of your machine.

Protecting Your Heat Press Platen

The upper platen of your heat press is the hot, flat metal surface that applies pressure. Inks from sublimation, residue from heat transfer vinyl (HTV), or adhesives from other materials can easily transfer onto this surface.

Without a protective sheet, this residue builds up, bakes onto the platen, and can then transfer to the next garment you press, ruining it. A protective sheet acts as a disposable or cleanable barrier, keeping your platen pristine.

Safeguarding Your Garment

A protective sheet shields your garment from two primary dangers. First, it prevents scorching or yellowing, which is especially common on light-colored polyester or blended fabrics.

Second, it provides a safety net if your vinyl or transfer is placed incorrectly. Any exposed adhesive or ink will stick to the protective sheet, not your expensive heat platen.

Ensuring an Even, Professional Finish

The sheet helps to distribute heat more evenly across the surface of the transfer. More importantly, the texture of the sheet itself can influence the final finish of the design. This is a key reason why professionals choose one type of sheet over another.

Comparing Your Protective Sheet Options

While the user asked about silicone paper, it's crucial to understand the three primary choices in the market, as each has a distinct purpose.

Teflon (PTFE) Sheets: The Reusable Workhorse

These are typically brown or white, semi-rigid sheets made of PTFE-coated fiberglass. They are the most durable and long-lasting option.

A single Teflon sheet can last for hundreds or even thousands of presses. It creates a slightly glossy finish on most heat transfer vinyls, which may or may not be desired.

Silicone-Coated Kraft Paper: The Professional Disposable

This is the product most people mean when they say "silicone paper." It's a heavy-duty paper with a silicone coating that gives it non-stick properties.

It is far less reusable than a Teflon sheet, often intended for single or limited use. Its key advantage is that it imparts a matte or textured finish to the transfer, which is often considered a more premium look. It is also the standard for protecting prints during the curing phase of Direct-to-Garment (DTG) printing.

Parchment Paper: The Accessible Alternative

This is standard, uncoated kitchen parchment paper. It is heat-resistant and non-stick, making it a viable option, especially for hobbyists or those in a pinch.

However, it is the least durable option. It will brown and become brittle after just a few presses and must be replaced frequently. It generally leaves a matte finish similar to silicone paper.

Understanding the Trade-offs

Choosing the right sheet involves balancing cost, durability, and the final aesthetic you want to achieve.

Reusability vs. Cost

A Teflon sheet has a higher upfront cost but is significantly cheaper over its lifespan due to its extreme reusability. Silicone and parchment papers have a very low cost per sheet but must be replaced frequently, which can add up over time in a high-volume environment.

The Impact on Finish

This is a critical factor for professionals. If you need a consistent glossy finish for your HTV products, a Teflon sheet is the standard choice. If you are aiming for a softer, matte finish that integrates more smoothly into the fabric, silicone-coated paper is superior.

The Critical Mistake: Avoid Wax and Butcher Paper

Never use wax paper. The wax will melt under the heat, transferring to both your garment and your heat press platen, creating a disastrous, greasy mess.

Similarly, butcher paper is not a suitable substitute. While some types are coated, many are not, and they lack the reliable non-stick and heat-resistant properties needed for pressing. Stick to products explicitly designed for heat applications.

Making the Right Choice for Your Goal

Your choice of protective sheet should be a deliberate decision based on your production needs.

- If your primary focus is maximum durability and cost-efficiency for general HTV work: Choose a Teflon (PTFE) sheet as your go-to tool.

- If your primary focus is achieving a premium matte finish or you are curing DTG prints: Use silicone-coated kraft paper for the best aesthetic results.

- If your primary focus is occasional hobby use or you need a quick, budget-friendly solution: High-quality kitchen parchment paper will work effectively, but be prepared to replace it often.

Mastering your protective layer is a simple but fundamental step toward achieving consistent, professional-grade results every time you press.

Summary Table:

| Protective Sheet Type | Primary Use | Finish | Reusability |

|---|---|---|---|

| Silicone-Coated Kraft Paper | DTG curing, matte finish HTV | Matte/Textured | Limited (disposable) |

| Teflon (PTFE) Sheet | General HTV work | Glossy | High (reusable) |

| Parchment Paper | Hobbyist, emergency use | Matte | Low (single/few uses) |

Achieve professional heat press results with the right protective sheets. KINTEK specializes in providing high-quality lab equipment and consumables, including heat press accessories tailored to your needs. Whether you're a professional printer or a hobbyist, our products ensure consistent, high-quality results while protecting your equipment. Contact us today to find the perfect solution for your heat press projects!

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Laboratory Heat Press Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

People Also Ask

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing