In certain specific cases, yes, but this is the exception, not the rule. While traditional annealing is known for softening materials and decreasing yield strength, specific low-temperature annealing processes can actually increase it by pinning internal defects in the material's crystal structure, making it harder to deform.

The term "annealing" covers a wide range of heat treatments. Its effect on yield strength is not universal; it is entirely dependent on the specific temperature, time, and the intended metallurgical goal of the process.

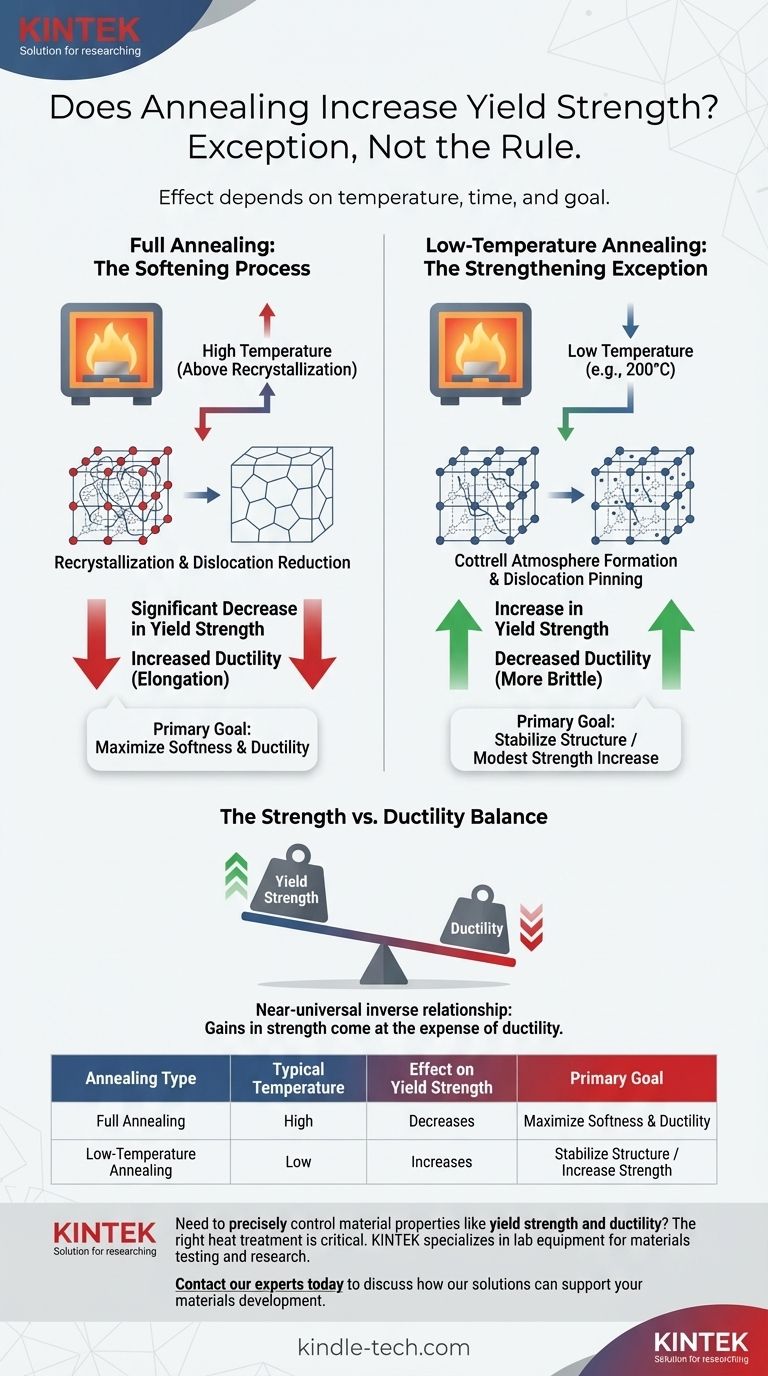

The Two Primary Effects of Annealing on Strength

"Annealing" is often used as a general term, but in materials science, the specific process parameters are what define the outcome. The effect on yield strength hinges on whether the goal is to soften the material completely or to simply stabilize its internal structure.

Full Annealing: The Softening Process

The most common understanding of annealing involves heating a material well above its recrystallization temperature. This process is designed to achieve maximum softness and ductility.

At these high temperatures, new, defect-free grains form within the material. This process, known as recrystallization, significantly reduces the density of dislocations—the microscopic defects that are tangled and pinned from previous work (like rolling or forging).

With fewer dislocations impeding movement within the crystal lattice, the material becomes much easier to deform. The result is a significant decrease in yield strength and an increase in ductility (elongation).

Low-Temperature Annealing: The Strengthening Exception

Conversely, specific low-temperature annealing cycles, often called stress-relief or aging processes, can increase yield strength. This occurs at temperatures too low for new grains to form.

Instead of eliminating dislocations, these lower temperatures give mobile atoms within the metal (like carbon in steel) enough energy to migrate. These atoms are drawn to the high-energy stress fields around existing dislocations.

This migration forms what is known as a Cottrell atmosphere, where the impurity atoms effectively "pin" the dislocations in place. To initiate plastic deformation, a higher stress is now required to break the dislocations away from this pinning atmosphere, leading to an increase in yield strength.

The provided reference describing an increase in the yield strength of X80 steel is a perfect example of this phenomenon. The 200 °C treatment was not hot enough to recrystallize the steel but was sufficient to allow carbon atoms to pin dislocations.

Understanding the Trade-offs

Choosing a heat treatment is always an exercise in balancing properties. The gains from one process often come at the expense of another characteristic.

The Strength vs. Ductility Balance

There is a near-universal inverse relationship between strength and ductility in metals. The same process that increases yield strength will almost always decrease ductility.

As seen in the reference material, the low-temperature anneal that increased yield strength by 10% also caused a 20% decrease in elongation. The pinning of dislocations makes the material stronger but also more brittle, as it can no longer deform as much before fracturing.

The Goal Dictates the Process

A manufacturer doesn't simply "anneal" a material; they select a precise thermal cycle to achieve a specific engineering goal.

If a steel sheet needs to be deep-drawn into a complex shape, it will undergo a full anneal to maximize its formability (low yield strength, high ductility). If a structural component needs to be stabilized after welding to prevent distortion, it will undergo a low-temperature stress-relief anneal, which may incidentally increase its yield strength.

Making the Right Choice for Your Goal

The correct annealing process is the one that achieves the desired end-state properties for your application.

- If your primary focus is maximum formability and ease of shaping: You need a full, high-temperature anneal to reduce yield strength and increase ductility.

- If your primary focus is stabilizing a component or achieving a modest strength increase in a previously worked material: A specific, low-temperature anneal (aging or stress relief) may be used to increase yield strength at the cost of some ductility.

Ultimately, the effect of annealing on yield strength is a direct consequence of the thermal pathway chosen and the metallurgical changes it is designed to produce.

Summary Table:

| Annealing Type | Typical Temperature | Effect on Yield Strength | Primary Goal |

|---|---|---|---|

| Full Annealing | High (Above Recrystallization) | Decreases | Maximize Softness & Ductility |

| Low-Temperature Annealing | Low (e.g., 200°C) | Increases | Stabilize Structure / Increase Strength |

Need to precisely control material properties like yield strength and ductility for your application?

The right heat treatment is critical to your product's performance. KINTEK specializes in lab equipment and consumables for materials testing and research, helping you analyze and achieve the perfect balance of strength and formability.

Contact our experts today to discuss how our solutions can support your materials development and quality control processes.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Can I solder copper to copper without flux? The Critical Role of Flux for a Strong Bond

- What are annealing applications in industry? Enhance Material Workability and Reliability

- Is brazing cheaper than welding? Optimize Your Metal Joining Costs for Production

- Why is a high-purity gas supply system necessary for ion carburizing? Ensure Precise Surface Integrity and Phase Purity

- Why is a laboratory vacuum oven used for the low-temperature drying of acid-functionalized nanoparticles?

- Why is a high-performance vacuum system required for alloy distillation? Boost Purity with 10–15 Pa Control

- Why is temperature important in casting? Master the Thermal Balance for Defect-Free Parts

- What kind of material is full annealing applied to? Optimize Steel for Maximum Machinability