Yes, but the critical factor is speed. A ceramic object can break due to a rapid and uneven temperature change, a phenomenon known as thermal shock. It isn't the temperature itself that causes the failure, but the stress created when one part of the ceramic expands or contracts much faster than another.

The core issue is that ceramics are poor conductors of heat. When you apply heat or cold to one area suddenly, that spot tries to expand or shrink while the rest of the material remains unchanged. This internal tug-of-war creates immense stress that can exceed the ceramic's strength, causing it to crack.

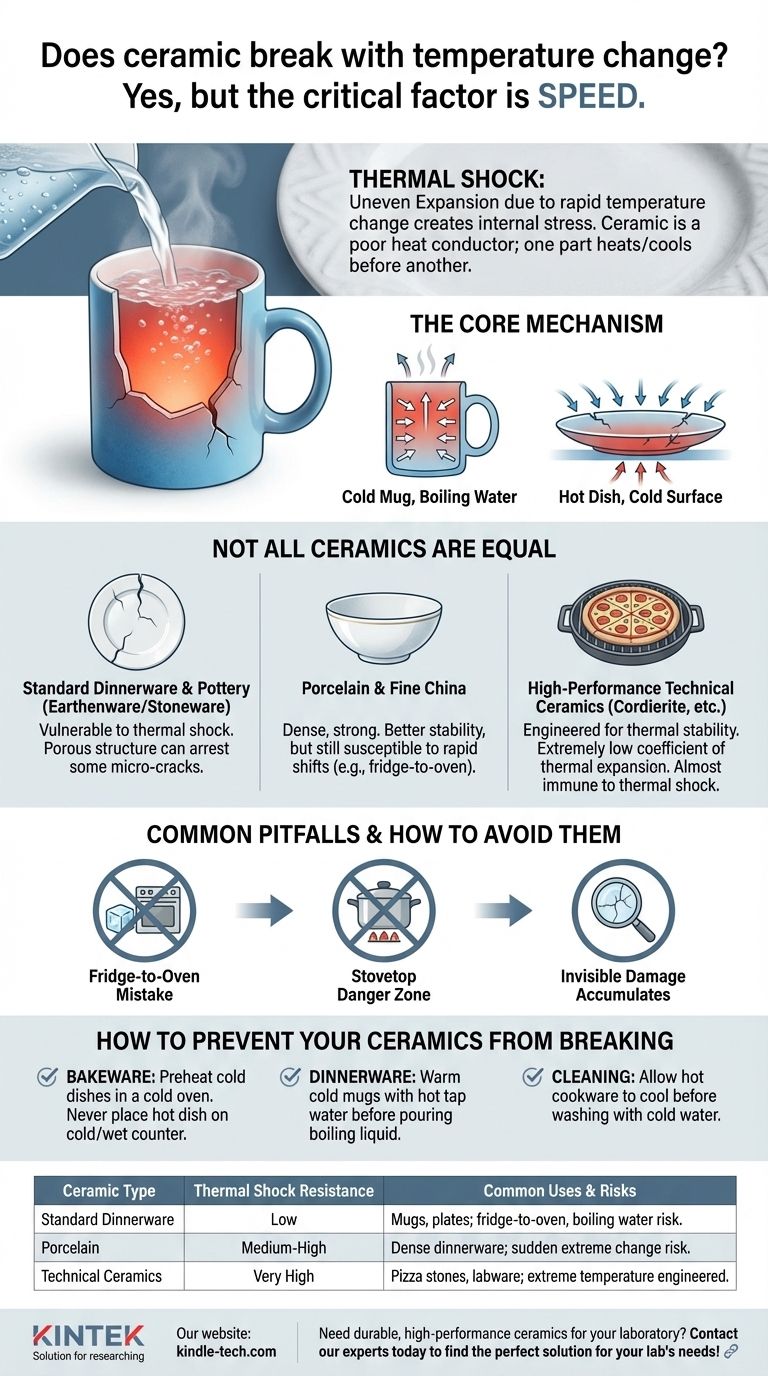

What is Thermal Shock?

The Core Mechanism: Uneven Expansion

Ceramic is a natural insulator, meaning heat does not travel through it quickly.

Imagine pouring boiling water into a cold ceramic mug. The inner surface heats up instantly and tries to expand. However, the outer surface is still cold and has not expanded yet.

This difference creates a powerful tension within the material's structure. If this stress is greater than the ceramic can handle, it will fracture to relieve the pressure. The same process happens in reverse when a hot dish is placed on a cold surface.

Internal Stress is the Enemy

Think of thermal shock as a buildup of internal stress. Every material has a breaking point, and for many ceramics, which are strong but brittle, that point can be reached surprisingly easily with a sudden temperature shift.

This is the same principle that causes a hot glass to shatter when plunged into cold water.

Why Material Composition Matters

The specific clay body and firing temperature of a ceramic piece heavily influence its resistance to thermal shock.

More porous ceramics, like earthenware, can sometimes tolerate shock better because the tiny air gaps in their structure can help arrest the spread of micro-cracks. Denser materials like porcelain are stronger overall but can be more prone to a complete, catastrophic fracture once a crack starts.

Not All Ceramics Are Created Equal

The term "ceramic" covers a vast range of materials, each engineered with different properties and tolerances.

Standard Dinnerware and Pottery

Most everyday mugs, plates, and decorative pottery (like earthenware and stoneware) are not designed to handle extreme temperature changes. They are most vulnerable to thermal shock.

Porcelain and Fine China

Fired at very high temperatures, porcelain is dense, strong, and non-porous. It generally has better thermal stability than basic pottery but is still highly susceptible to the rapid shock of moving from a refrigerator to a hot oven.

High-Performance Technical Ceramics

Specialized ceramics are engineered specifically for thermal stability. Materials like cordierite (used in pizza stones) and lithium aluminosilicates (used in glass-ceramic cookware) have an extremely low coefficient of thermal expansion.

This means they barely expand or contract when heated or cooled, making them almost immune to the stresses of thermal shock. This is why you can take a pizza stone to very high temperatures without issue.

Common Pitfalls and How to Avoid Them

The Fridge-to-Oven Mistake

The most common cause of broken bakeware is placing a cold ceramic dish directly into a preheated oven. The outer layers heat rapidly while the core remains cold, guaranteeing a stress fracture.

The Stovetop Danger Zone

Ceramic bakeware or dinnerware should never be used on a direct heat source like a stovetop burner. The intense, concentrated heat will cause a rapid, localized expansion that will almost certainly crack the piece.

Invisible Damage Accumulates

Even if a ceramic piece doesn't shatter, a minor thermal shock can create invisible micro-cracks. Over time, with repeated temperature stress, these tiny cracks can grow until the item fails unexpectedly during normal use.

The "Oven Safe" Misconception

When a product is labeled "oven safe," it means it can withstand the gradual heating and cooling of a conventional oven cycle. It does not mean it is immune to thermal shock.

How to Prevent Your Ceramics from Breaking

- If your primary focus is bakeware: Always place a cold ceramic dish in a cold oven and let them preheat together. Never take a hot dish out of the oven and place it on a cold or wet countertop.

- If your primary focus is dinnerware: Avoid pouring boiling water directly into a very cold mug or bowl. To be safe, warm the vessel with hot tap water first.

- If your primary focus is cleaning: Always allow hot ceramic cookware to cool to room temperature before washing it with cold water.

Understanding the principle of gradual temperature change is the key to preserving your ceramic items for a lifetime.

Summary Table:

| Ceramic Type | Thermal Shock Resistance | Common Uses & Risks |

|---|---|---|

| Standard Dinnerware (Earthenware/Stoneware) | Low | Mugs, plates; risk from fridge-to-oven or boiling water. |

| Porcelain / Fine China | Medium-High (but still vulnerable) | Dense dinnerware; risk from sudden, extreme changes. |

| Technical Ceramics (Cordierite) | Very High | Pizza stones, labware; engineered for extreme temperatures. |

Need durable, high-performance ceramics for your laboratory? At KINTEK, we specialize in lab equipment and consumables designed to withstand demanding thermal cycles. Our technical ceramics ensure reliability and longevity for your precise applications. Contact our experts today to find the perfect solution for your lab's needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Double Plate Heating Press Mold for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis