In short, induction heating is overwhelmingly used for metals, but it's not strictly limited to them. The technology works on any material that is either a good electrical conductor or has strong magnetic properties. While this describes most metals, it also includes a few specific non-metals like graphite and silicon carbide.

The question isn't whether a material is a metal, but whether it possesses the right electrical and magnetic properties. Induction heating works by converting electromagnetic energy into heat, a process that requires a material to be either electrically conductive or to exhibit magnetic hysteresis.

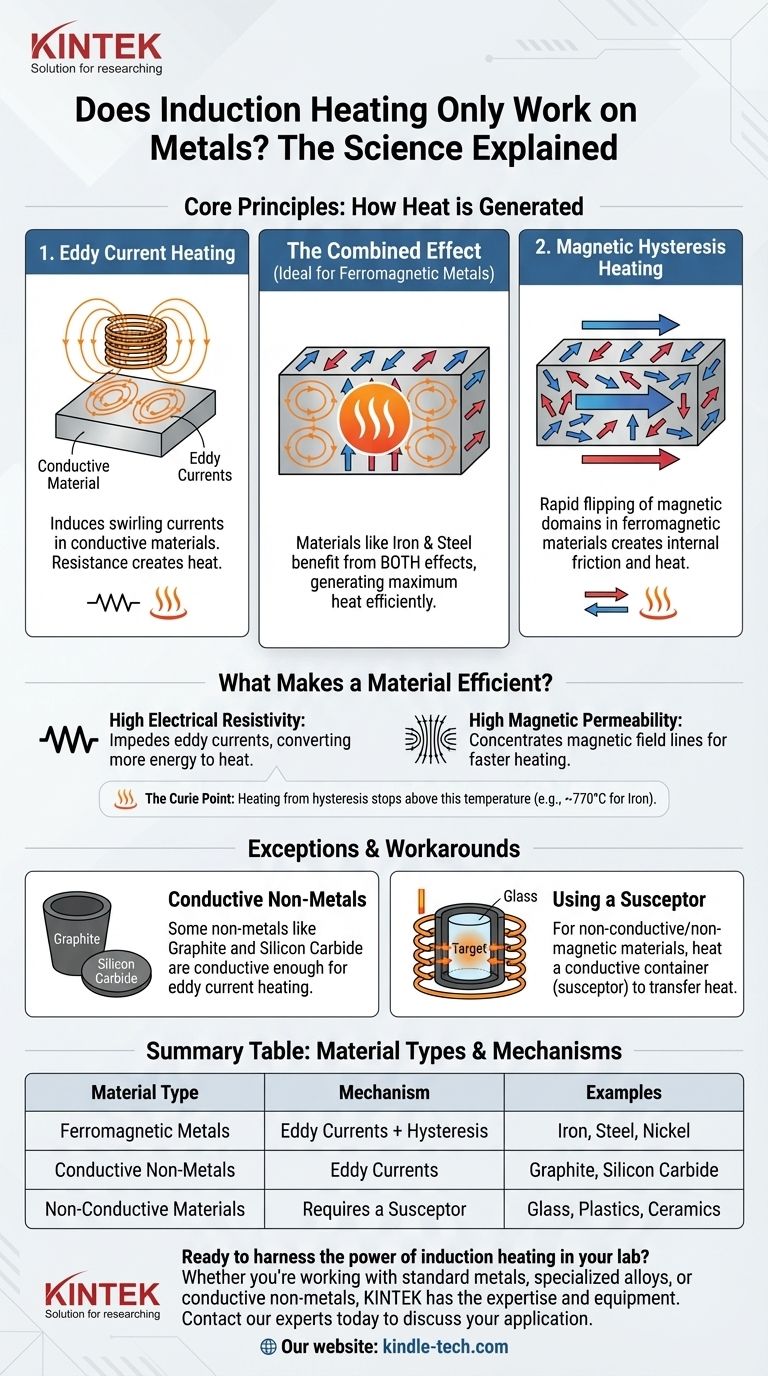

The Core Principles: How Induction Generates Heat

To understand which materials work, you must first understand the two phenomena that generate heat in an induction system. A material only needs one of these properties to be heated, but the best materials have both.

Eddy Current Heating

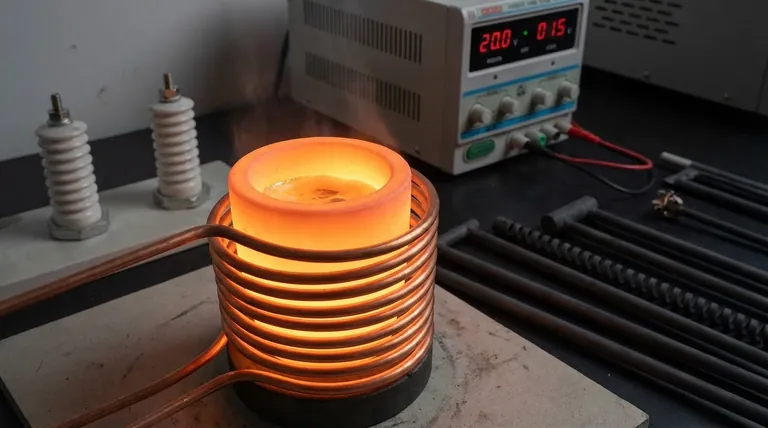

An induction coil generates a powerful, rapidly alternating magnetic field.

When an electrically conductive material is placed in this field, it induces small, swirling electrical currents within the material, known as eddy currents.

Because every material has some electrical resistance, these currents generate heat as they flow, much like the element in an electric stove. This is the primary way conductive materials like copper or aluminum can be heated.

Magnetic Hysteresis Heating

This effect only occurs in ferromagnetic materials, such as iron, nickel, and cobalt.

These materials are composed of tiny magnetic regions called "domains." When exposed to the alternating magnetic field, these domains rapidly flip their orientation to align with the field.

This rapid flipping creates significant internal friction, which generates a tremendous amount of heat. This process is known as hysteresis loss.

The Combined Effect in Ferromagnetic Metals

Materials like iron and steel are ideal for induction heating because they benefit from both effects simultaneously.

They are electrically conductive, allowing for powerful eddy currents. They are also ferromagnetic, generating intense heat through hysteresis. This dual-action heating is why induction cooktops work so effectively with cast iron and stainless steel pans.

What Makes a Material "Good" for Induction?

Beyond the basic principles, a few key properties determine how efficiently a material will heat.

Electrical Resistivity

Somewhat counterintuitively, materials with extremely high electrical conductivity (like copper) are harder to heat. Their low resistance means the eddy currents flow easily without generating much friction (heat).

Materials with higher resistivity, like steel or titanium, impede the flow of these currents more, converting more electrical energy into heat.

Magnetic Permeability

Permeability is a measure of how easily a material can be magnetized.

High magnetic permeability, a characteristic of ferromagnetic materials, concentrates the magnetic field lines. This intensifies both the eddy currents and the hysteresis effect, leading to much faster and more efficient heating.

The Curie Point Limitation

Ferromagnetic materials lose their magnetic properties above a specific temperature, known as the Curie point (around 770°C or 1420°F for iron).

Above this temperature, all heating from magnetic hysteresis stops. The material can still be heated further by eddy currents alone, but the heating rate will decrease significantly.

The Exceptions and Workarounds

While induction is metal-focused, there are important exceptions and clever techniques for heating other materials.

Heating Conductive Non-Metals

Some non-metals are sufficiently conductive to be heated directly by eddy currents.

The most common examples are graphite, carbon fiber, and some semiconductors like silicon carbide. These materials are used in specialized industrial and scientific applications.

Using a Susceptor

For materials that are neither conductive nor magnetic (like glass, plastics, or ceramics), a clever workaround is employed.

The target material is placed inside a container made of a conductive material, often graphite. This container, called a susceptor, is heated by the induction field. The susceptor then transfers its heat to the target material via conventional conduction or radiation.

Making the Right Choice for Your Goal

Understanding these principles allows you to select the right material or strategy for your specific application.

- If your primary focus is maximum heating efficiency: Choose ferromagnetic metals like carbon steel, cast iron, or 400-series stainless steel.

- If you must heat a non-conductive or non-magnetic material: Use a conductive susceptor, such as a graphite crucible, to act as the heating element.

- If you are working with high-conductivity metals like copper or aluminum: Be prepared for lower efficiency and the need for a system with much higher power and frequency.

Ultimately, success with induction heating comes from matching the material's properties to the principles of electromagnetism.

Summary Table:

| Material Type | Induction Heating Mechanism | Common Examples |

|---|---|---|

| Ferromagnetic Metals | Eddy Currents + Magnetic Hysteresis | Iron, Steel, Nickel |

| Conductive Non-Metals | Eddy Currents | Graphite, Silicon Carbide |

| Non-Conductive Materials | Requires a Susceptor | Glass, Plastics, Ceramics |

Ready to harness the power of induction heating in your lab? Whether you're working with standard metals, specialized alloys, or conductive non-metals like graphite, KINTEK has the expertise and equipment to meet your needs. Our advanced induction heating systems are designed for precision, efficiency, and reliability. Contact our experts today to discuss your specific application and discover how KINTEK can enhance your laboratory processes with the right solution.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Automatic Laboratory Heat Press Machine

- Double Plate Heating Press Mold for Lab

- Three-dimensional electromagnetic sieving instrument

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- Why use vacuum induction melting and water atomization for Cu-Re powders? Achieve Purity and High Density.

- Can an induction coil melt steel? Unlock Fast, Efficient Industrial Melting

- What is the voltage limit in an induction furnace? It's a Tale of Two Power Systems

- What is induction heating also known as? The Science of Eddy Current Heating Explained

- How does an induction furnace with a steel core generate heat for melting copper alloys? Efficiency and Principles

- Which furnace is the best to melt scrap? Discover the Speed and Efficiency of Induction Heating

- How does high frequency induction heating work? Unlock Fast, Precise, and Efficient Heat

- How many times can metal be melted down and used again? The Key to Infinite Recyclability