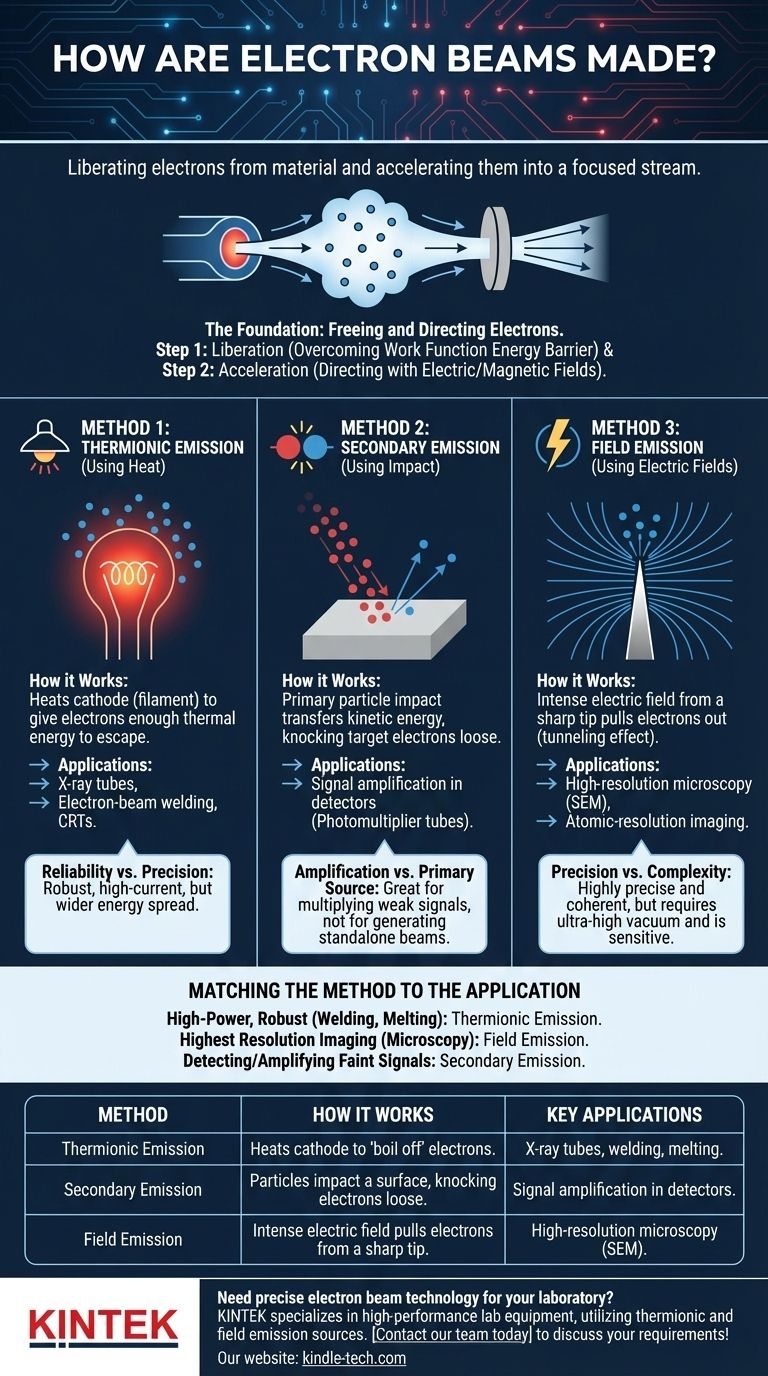

In essence, an electron beam is created by liberating electrons from a material and then accelerating them into a focused stream. The three primary methods for liberating these electrons are fundamentally different, relying on intense heat (thermionic emission), high-energy particle bombardment (secondary emission), or powerful electric fields (field emission). Each method is chosen based on the desired characteristics of the final beam.

The creation of any electron beam comes down to a single principle: providing enough energy to an electron to overcome the forces holding it inside a material. The method you use to supply that energy—be it heat, impact, or an electric field—determines the nature and application of the beam.

The Foundation: Freeing and Directing Electrons

Before examining the specific methods, it's crucial to understand the two-step process common to all electron beam generation: liberation and acceleration. An electron source, or cathode, must first release electrons.

The Energy Barrier (Work Function)

Every conductive material holds onto its electrons with a certain amount of energy. This "escape energy" is known as the work function.

The entire goal of an electron source is to impart enough energy to electrons to overcome this work function, freeing them from the surface of the material.

The Role of Acceleration

Once freed, the electrons are directed and accelerated by electric and/or magnetic fields. This process forms them into a coherent, focused stream—the electron beam.

The Three Core Generation Methods

The key difference between electron beam sources lies in how they give electrons the energy to escape the cathode material.

Method 1: Thermionic Emission (Using Heat)

This is the classic and most established method for generating electron beams. The principle is analogous to boiling water.

By heating a cathode material (often a filament), you transfer thermal energy to its electrons. As the electrons vibrate more intensely, some gain enough kinetic energy to overcome the work function and "boil off" the surface.

This method is reliable and capable of producing high-current beams. It was the foundation of cathode-ray tubes (CRTs) used in old televisions and is still used in X-ray tubes and electron-beam welding.

Method 2: Secondary Emission (Using Impact)

This method generates electrons by using other particles as a trigger. A primary beam of particles, such as electrons or ions, is fired at a target material.

The kinetic energy from this impact is transferred to electrons within the target. This collision can give the target's electrons enough energy to be knocked loose from the surface.

This process is fundamental to devices like photomultiplier tubes, where a single incoming photon can trigger a cascade of secondary electrons, amplifying a very weak signal.

Method 3: Field Emission (Using Electric Fields)

Field emission operates without significant heat. Instead, it uses an extremely strong external electric field to pull electrons directly out of the cathode.

The cathode is shaped into a very sharp point, which concentrates the electric field to immense levels. This intense field effectively lowers the work function barrier and coaxes electrons to "tunnel" out of the material.

This method produces a very narrow, coherent, and high-brightness beam, making it essential for high-resolution applications like scanning electron microscopes (SEMs).

Understanding the Trade-offs

No single method is universally superior; the choice is dictated by the needs of the application. Understanding their inherent compromises is key to understanding their use.

Thermionic Emission: Reliability vs. Precision

Thermionic sources are robust and can generate powerful beams. However, the electrons are emitted with a relatively wide spread of energies, which limits the ultimate focus and resolution of the beam.

Field Emission: Precision vs. Complexity

Field emission sources provide the most precise and coherent beams, enabling applications like atomic-resolution imaging. Their major drawback is extreme sensitivity; they require an ultra-high vacuum to operate and are easily damaged by surface contamination.

Secondary Emission: Amplification vs. Primary Source

Secondary emission is less a method for creating a primary, standalone beam and more a mechanism for amplification. Its great strength is multiplying a weak incoming signal, but it is not typically used to generate a beam from scratch for applications like welding or lithography.

Matching the Method to the Application

Your choice of generation method is entirely dependent on what you need the electron beam to accomplish.

- If your primary focus is creating a high-power, robust beam for welding, melting, or sterilization: Thermionic emission is the proven, workhorse method.

- If your primary focus is achieving the highest possible resolution for imaging individual atoms in microscopy: Field emission is the required technology, despite its complexity.

- If your primary focus is detecting or amplifying a very faint signal of light or particles: Secondary emission is the core principle used in sensitive detectors.

Ultimately, understanding these fundamental generation methods allows you to see how a vast range of technologies, from old televisions to cutting-edge microscopes, all function by manipulating the electron.

Summary Table:

| Method | How It Works | Key Applications |

|---|---|---|

| Thermionic Emission | Heats a cathode to 'boil off' electrons. | X-ray tubes, welding, melting. |

| Secondary Emission | Particles impact a surface, knocking electrons loose. | Signal amplification in detectors. |

| Field Emission | Intense electric field pulls electrons from a sharp tip. | High-resolution microscopy (SEM). |

Need precise electron beam technology for your laboratory? KINTEK specializes in high-performance lab equipment, including systems utilizing thermionic and field emission sources for applications from materials processing to advanced imaging. Our experts can help you select the ideal technology to meet your specific research or production goals. Contact our team today to discuss your requirements!

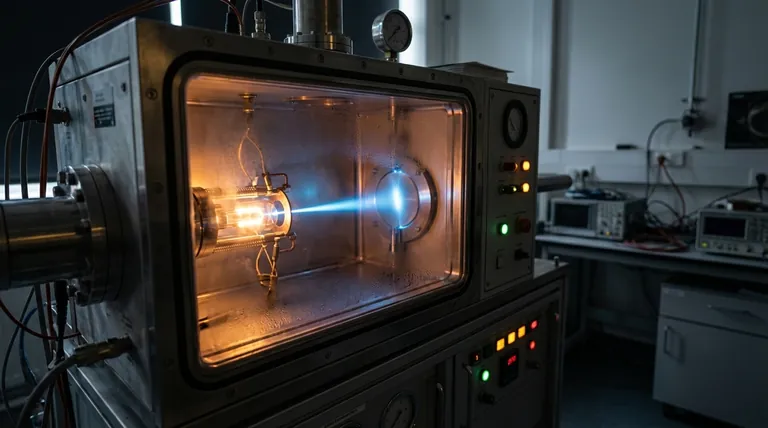

Visual Guide

Related Products

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- How does a water bath work? Master Precise and Gentle Heating for Your Lab

- How do constant temperature circulators impact weight-loss immersion tests? Ensure Precision in Corrosion Analysis

- How does a thermostatic water bath function in ODS steel corrosion tests? Ensure Precise Bio-Simulation Accuracy

- What is the primary function of water baths and chillers? Mastering Precise Thermal Stability for Liquid Samples

- For which types of substances are water baths and chillers considered ideal? Essential Care for Sensitive Samples