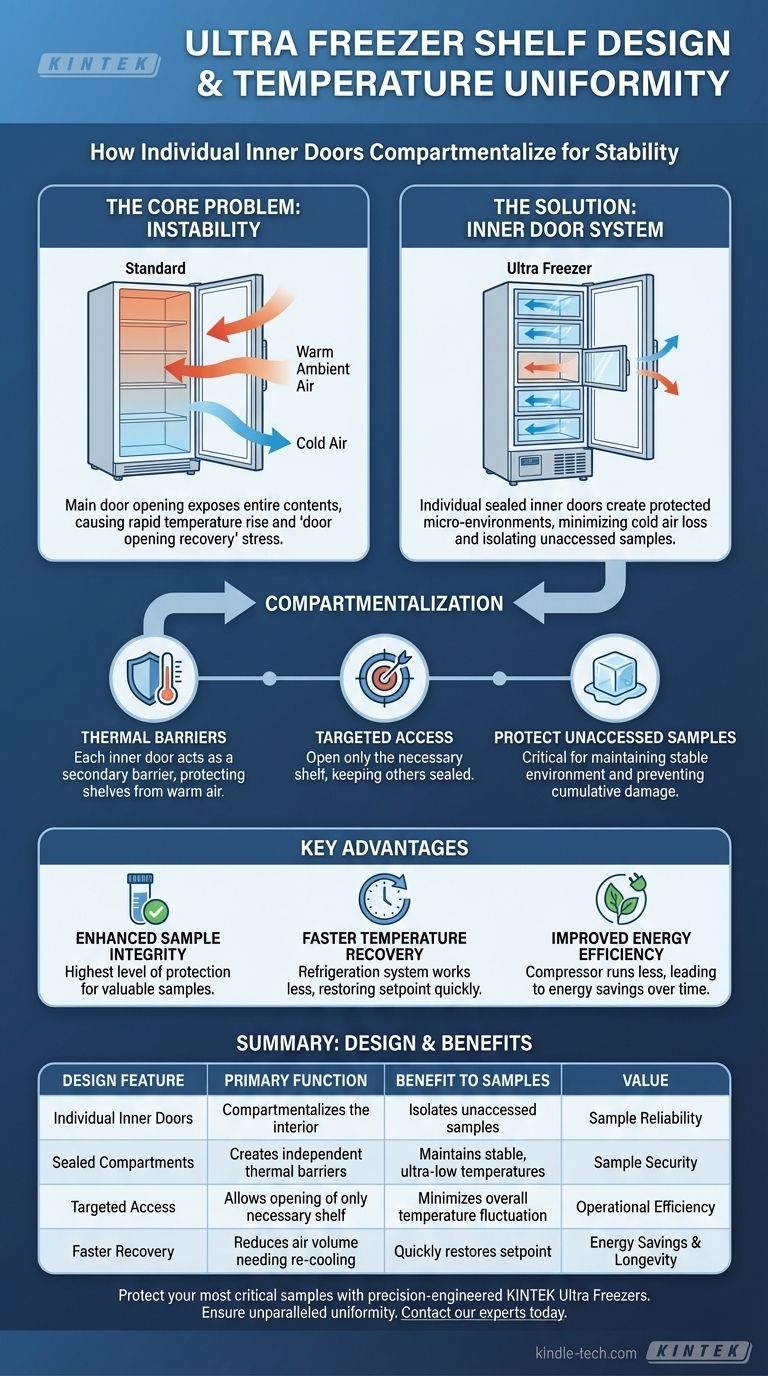

To maintain temperature uniformity, Ultra Freezers are engineered with individual, sealed inner doors for each shelf. This design compartmentalizes the interior, ensuring that when you access one shelf, the others remain sealed off from the warmer ambient air, preserving their stable, ultra-low temperature environment.

The fundamental strategy behind Ultra Freezer shelf design is compartmentalization. By using individual inner doors for each shelf, the freezer minimizes cold air loss and protects unaccessed samples from the thermal shock that occurs whenever the main door is opened.

The Core Problem: Temperature Instability During Access

Any time a freezer door is opened, a battle against physics begins. Understanding this challenge is key to appreciating the engineering behind the shelves.

What Happens When a Standard Freezer is Opened

When the main door of a freezer is opened, the dense, ultra-cold air inside immediately flows out and is replaced by warmer, more humid ambient air.

This exchange instantly raises the internal temperature, forcing the freezer's cooling system to work overtime to return to its setpoint. This event is known as a "door opening recovery."

The Consequence of Poor Uniformity

For sensitive biological samples, enzymes, or reagents stored in an Ultra Freezer, even brief temperature fluctuations can be catastrophic.

Repeated warming events can degrade sample quality, compromise experimental integrity, and lead to inconsistent or invalid research results. The stability of the entire inventory is put at risk.

The Engineering Solution: The Inner Door System

The use of internal doors is a direct and highly effective solution to the problem of temperature loss. It turns the single large interior space into a series of protected micro-environments.

Creating Thermal Barriers

Each inner door acts as a secondary thermal barrier. While the main outer door provides the primary seal and insulation for the entire unit, the inner doors isolate each shelf.

This means when you open the main door, you are not immediately exposing your entire collection of samples to room temperature.

Minimizing Cold Air Loss

The system allows for targeted access. If you only need a sample from the third shelf, you only open that specific inner door.

The cold air in the other sealed compartments remains largely undisturbed. This dramatically reduces the volume of cold air lost and warm air gained during access, localizing the temperature fluctuation to a very small area.

Protecting Unaccessed Samples

This is the most critical benefit. Samples on shelves that remain closed are shielded from the thermal disruption.

Their environment stays exceptionally stable and uniform, preserving their integrity even when the freezer is accessed frequently. This design directly prevents the cumulative damage that can occur from repeated temperature swings.

Key Advantages of the Internal Door System

This seemingly simple design feature has profound implications for laboratory operations, leading to better science and greater efficiency.

Enhanced Sample Integrity

By preventing drastic temperature spikes across the entire cabinet, the inner door system provides the highest level of protection for valuable and often irreplaceable samples.

Faster Temperature Recovery

Because far less cold air is lost during a targeted door opening, the freezer's refrigeration system has to do significantly less work to return to its setpoint.

This leads to much faster temperature recovery times, meaning the freezer spends more time at the optimal storage temperature.

Improved Energy Efficiency

Faster recovery and a more stable internal environment mean the compressor runs less often and for shorter durations. Over the life of the unit, this translates to considerable energy savings.

Applying This to Your Protocol

Understanding this design principle allows you to optimize how you use the freezer to protect your work.

- If your primary focus is long-term archival storage: Group samples by project or date and keep them behind dedicated, infrequently opened inner doors to maximize stability.

- If your primary focus is frequent sample access: Designate one or two shelves for your active working samples to contain the impact of regular door openings, leaving the other compartments undisturbed.

This shelf design is a critical feature that directly contributes to the safety of your samples and the reliability of your research.

Summary Table:

| Design Feature | Primary Function | Benefit to Samples |

|---|---|---|

| Individual Inner Doors | Compartmentalizes the interior space | Isolates unaccessed samples from warm air during door openings |

| Sealed Compartments | Creates independent thermal barriers | Maintains stable, ultra-low temperatures in unopened sections |

| Targeted Access | Allows opening of only the necessary shelf | Minimizes overall cold air loss and temperature fluctuation |

| Faster Recovery | Reduces the volume of air needing re-cooling | Quickly restores setpoint temperature, protecting sample integrity |

Protect your most critical samples with precision-engineered lab equipment from KINTEK. Our Ultra Freezers are designed with the advanced compartmentalization technology detailed above, ensuring unparalleled temperature uniformity and sample security. Whether you're managing long-term archives or require frequent access, KINTEK's reliable lab equipment is built to support the integrity of your research. Contact our experts today to find the perfect storage solution for your laboratory's specific needs.

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Assemble Square Lab Press Mold for Laboratory Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- What is the cryogenic grinding process? Achieve Superior Quality and Efficiency for Sensitive Materials

- What is cool grinding technology? Unlock Efficient Milling for Heat-Sensitive Materials

- What is cryogenic grinding of cardamom? Preserve Flavor, Aroma & Color with Extreme Cold

- What process advantages are offered by integrating a cryogenic cooling device during HPT? Achieve Ultimate Grain Refinement