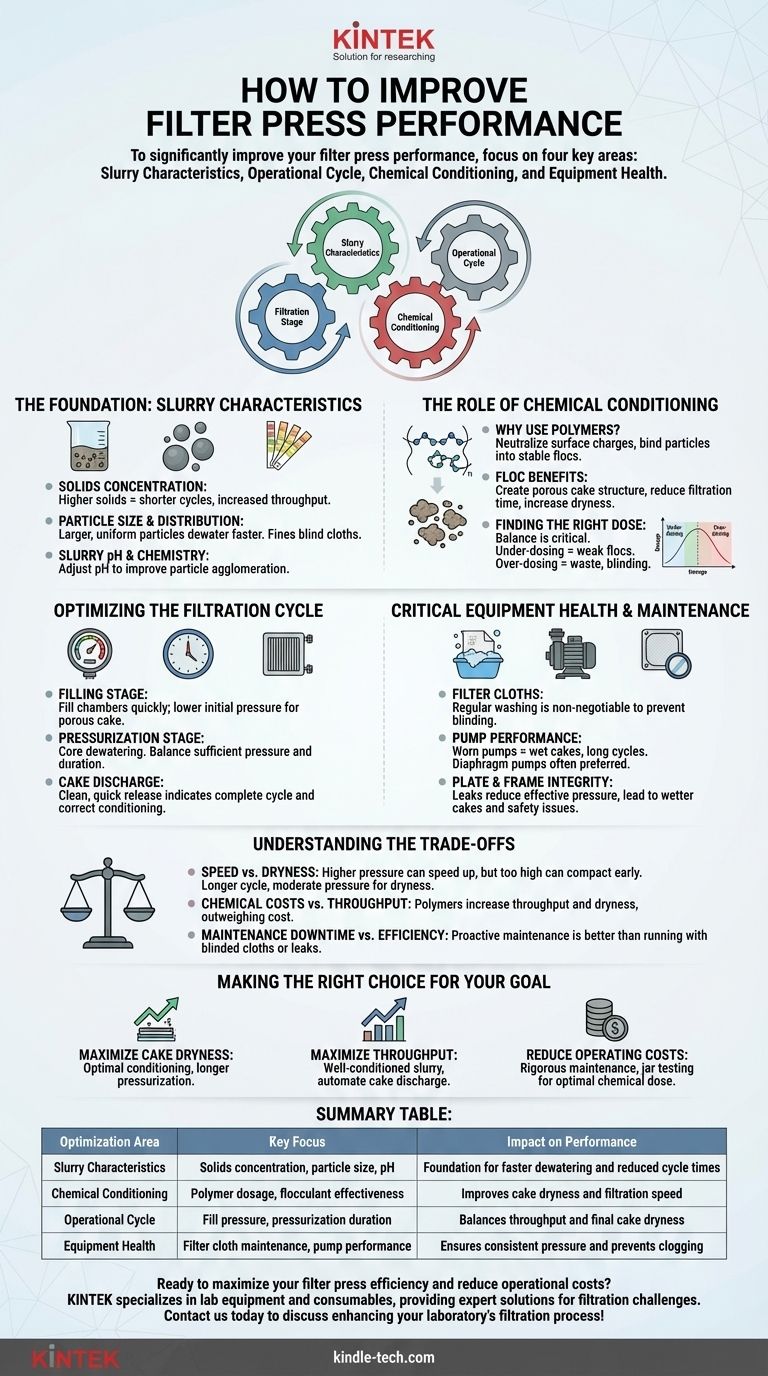

To significantly improve your filter press performance, you must focus on four key areas: the characteristics of the feed slurry, the optimization of the operational cycle (pressure and time), the effectiveness of chemical conditioning, and the health of your equipment, especially the filter cloths. Improving any one of these can yield benefits, but optimizing them as an integrated system delivers the most dramatic and sustainable results.

Filter press optimization is not about a single magic setting, but about systematically balancing the slurry's characteristics, the operational cycle, and the equipment's condition. The greatest gains are found by treating filtration as a complete process, not just a mechanical step.

The Foundation: Slurry Characteristics

The material you feed into the press is the single most important factor determining its performance. An inconsistent or poorly conditioned slurry will undermine all other optimization efforts.

Solids Concentration

A higher concentration of solids in the feed slurry means there is less water to remove per cycle. This directly translates to shorter cycle times and increased overall throughput.

Particle Size and Distribution

Fine particles, or "fines," are notoriously difficult to dewater and can quickly blind the filter cloths. A slurry with larger, more uniform particles will dewater much faster and more completely.

Slurry pH and Chemistry

The surface charge of particles, influenced by pH, can cause them to repel each other and resist agglomeration. Adjusting the pH can sometimes be a simple first step to improve how particles group together for easier dewatering.

The Role of Chemical Conditioning

For many slurries, especially those with fine particles, mechanical pressing alone is inefficient. Chemical conditioners are essential tools for preparing the slurry for effective dewatering.

Why Use Polymers?

Polymers, specifically flocculants, are long-chain molecules that neutralize the surface charges of fine particles. This allows the particles to bind together into larger, more stable aggregates called "flocs."

These flocs create a more porous and stable cake structure. This structure allows water to escape more easily during the pressing cycle, drastically reducing filtration time and increasing final cake dryness.

Finding the Right Dose

Polymer dosage is a critical balancing act. Under-dosing results in weak flocs and poor performance. Over-dosing is wasteful, can "slime" the particles, and blind the filter cloths, which is often worse than using no polymer at all. Jar testing is a crucial step to determine the optimal dosage for your specific slurry.

Optimizing the Filtration Cycle

The operational parameters you set for the filter press directly control the balance between speed and efficiency.

The Filling Stage

The goal of the fill stage is to fill every chamber with slurry as quickly as possible without prematurely forming a dense, impermeable cake against the cloth. Using a lower initial feed pressure can help build a more porous initial cake layer.

The Pressurization Stage

This is the core dewatering phase. Ramping up the feed pressure forces water out of the cake. The key is applying sufficient pressure for a sufficient duration to achieve the target cake dryness without blinding the filter media.

Cake Discharge

A dry, well-formed cake will release cleanly and quickly from the cloths. If cakes are sticky and difficult to remove, it's a clear indicator that your dewatering cycle is incomplete or your slurry conditioning is off.

Critical Equipment Health & Maintenance

Even a perfectly conditioned slurry and an optimized cycle will fail if the equipment is not in good working order.

Filter Cloths: The Unsung Hero

Filter cloths are the most critical component. If they are blinded (clogged with fine particles), water cannot pass through, no matter how high you raise the pressure. Regular and effective cloth washing is non-negotiable for consistent performance.

Pump Performance

The feed pump must be capable of delivering the required volume at the necessary pressure. A worn or improperly sized pump will be unable to achieve the target pressure, leading to wet cakes and extended cycle times. Diaphragm pumps are often preferred for their ability to handle solids and variable pressures.

Plate and Frame Integrity

Leaking plates or damaged cloth sealing surfaces reduce the effective pressure within the chambers. This results in wetter cakes, especially in the areas around the leak, and creates safety and housekeeping issues.

Understanding the Trade-offs

Improving filter press performance is rarely about maximizing one variable. It involves making intelligent compromises.

Speed vs. Dryness

Increasing feed pressure can shorten cycle times, but excessively high pressure can compact the cake too early, trapping water inside and blinding the cloths. Sometimes, a longer cycle at a more moderate pressure yields a much drier final product.

Chemical Costs vs. Throughput

Polymers are a direct operational cost, but their ability to dramatically increase throughput and cake dryness often provides a return on investment that far outweighs the expense. Starving the process of chemicals to save money can lead to higher costs in labor, transport, and disposal of wet cake.

Maintenance Downtime vs. Efficiency

Taking the press offline for a thorough cloth wash or plate maintenance costs time in the short term. However, running with blinded cloths or leaking plates is far more inefficient and costly over the long term due to poor performance and potential equipment damage.

Making the Right Choice for Your Goal

Your optimization strategy should be guided by your primary objective.

- If your primary focus is maximizing cake dryness: Prioritize optimal chemical conditioning for strong flocs and allow for a longer pressurization cycle to expel the maximum amount of water.

- If your primary focus is maximizing throughput: Focus on a well-conditioned slurry for rapid initial dewatering and automate the cake discharge process to minimize time between cycles.

- If your primary focus is reducing operating costs: Implement a rigorous preventative maintenance schedule for cloths and pumps, and use jar testing to ensure you are not over-dosing expensive chemicals.

A systematic approach to these variables will transform your filter press from a simple machine into a highly efficient and reliable process asset.

Summary Table:

| Optimization Area | Key Focus | Impact on Performance |

|---|---|---|

| Slurry Characteristics | Solids concentration, particle size, pH | Foundation for faster dewatering and reduced cycle times |

| Chemical Conditioning | Polymer dosage, flocculant effectiveness | Improves cake dryness and filtration speed |

| Operational Cycle | Fill pressure, pressurization duration | Balances throughput and final cake dryness |

| Equipment Health | Filter cloth maintenance, pump performance | Ensures consistent pressure and prevents clogging |

Ready to maximize your filter press efficiency and reduce operational costs? KINTEK specializes in lab equipment and consumables, providing expert solutions for filtration challenges. Our team can help you optimize slurry conditioning, cycle parameters, and equipment maintenance for superior performance. Contact us today to discuss how we can enhance your laboratory's filtration process!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis