Cleaning a vacuum furnace is a systematic process that goes beyond a simple wipe-down. It involves inspecting and mechanically cleaning the internal chamber and fixtures, followed by a "burn-off" or dry run-out cycle to vaporize residual contaminants. This procedure is a critical part of a broader maintenance strategy designed to protect the furnace and ensure the quality of the parts being processed.

The core challenge in vacuum furnace operation is managing contamination. Effective cleaning is not a one-time task but a routine discipline essential for achieving deep vacuum levels, preventing workpiece defects, and maximizing the operational life of the furnace.

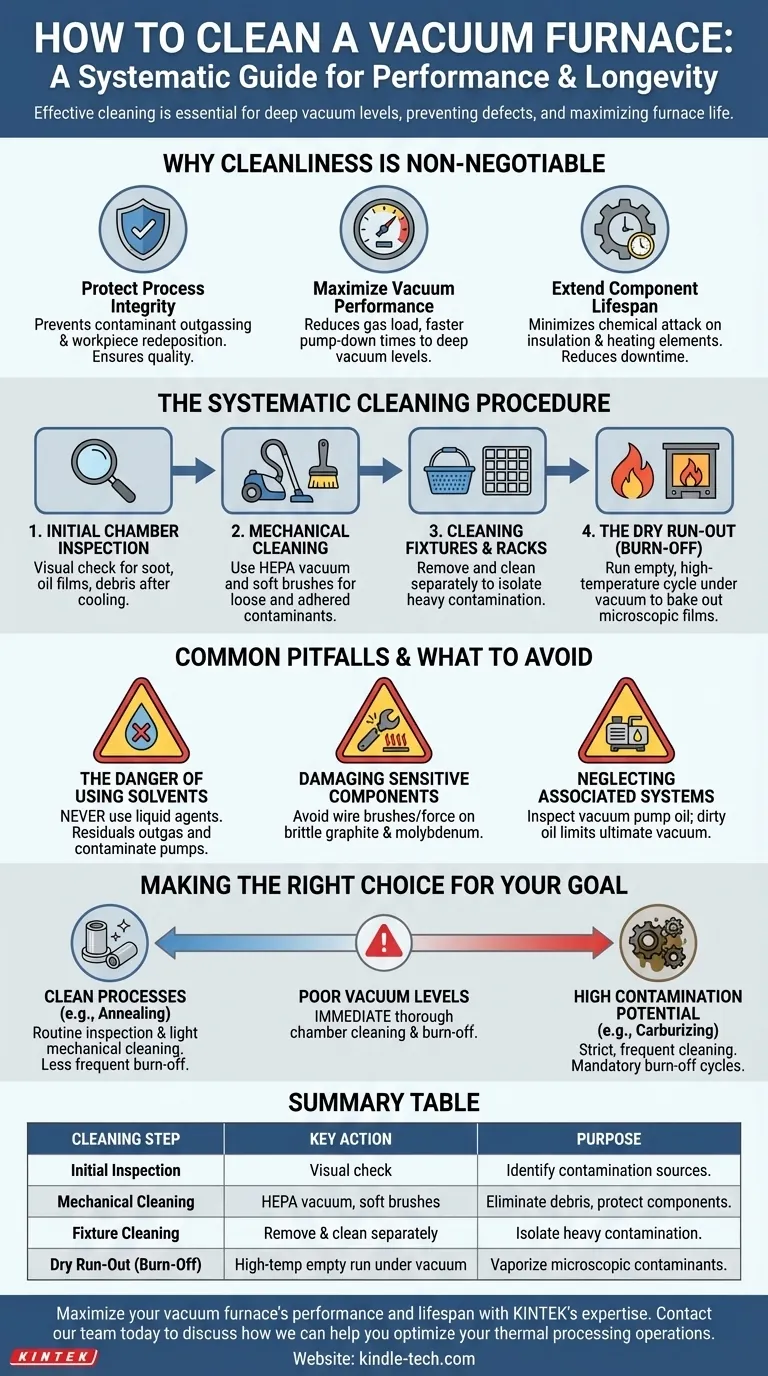

Why Furnace Cleanliness is Non-Negotiable

A clean vacuum furnace is the foundation of any successful thermal process. Contamination is the primary enemy, directly impacting performance, reliability, and the quality of your end product.

Protecting Process Integrity

Contaminants like oils, dust, or residual oxides left inside the furnace can vaporize at high temperatures and low pressures. This phenomenon, known as outgassing, can redeposit these contaminants onto your workpiece.

This can lead to discoloration, surface blemishes, or compromised metallurgical properties, nullifying the benefits of processing in a vacuum.

Maximizing Vacuum Performance

Every contaminant on the furnace walls has a vapor pressure and will contribute to the gas load that the vacuum pumps must handle. A dirty furnace chamber will continuously outgas, making it much harder and slower to reach the required deep vacuum level.

This extends cycle times, increases energy consumption, and may even prevent the furnace from reaching the necessary vacuum for a specific process.

Extending Component Lifespan

Certain contaminants can become chemically reactive at high temperatures. These residues can attack the furnace's expensive internal components, such as graphite or ceramic insulation and metallic heating elements.

Over time, this chemical attack leads to degradation, premature failure, and costly downtime for repairs and replacement.

The Systematic Cleaning Procedure

A proper cleaning protocol is methodical and focuses on removing contaminants without damaging sensitive furnace components. Always consult your furnace manufacturer's specific guidelines and wear appropriate personal protective equipment (PPE), including gloves and respiratory protection.

Step 1: Initial Chamber Inspection

After the furnace has cooled completely and is vented to atmosphere, begin with a thorough visual inspection. Open the door and look for obvious sources of contamination.

Common culprits include soot from dirty processes, oil films from fingerprints or contaminated parts, and small flakes of metal or oxide from previous workloads.

Step 2: Mechanical Cleaning

The primary method for cleaning the hot zone is mechanical removal. Use a dedicated, high-efficiency particulate air (HEPA) filter vacuum cleaner to remove all loose dust and debris.

For adhered films or deposits, gently use soft, non-metallic bristle brushes or abrasive pads (like Scotch-Brite™). Work methodically from the top down. Pay special attention to the areas around heating element supports and gas quench nozzles.

Step 3: Cleaning Fixtures and Racks

Workpiece grids, baskets, and fixtures are often the most contaminated items. Remove them from the furnace for separate, more aggressive cleaning. This isolates the heaviest contamination and prevents it from being spread around the hot zone.

Step 4: The Dry Run-Out (Burn-Off Cycle)

After mechanical cleaning, a high-temperature dry run-out is the final and most critical step. This involves running the empty, sealed furnace to a high temperature under vacuum.

This cycle vaporizes any remaining microscopic films of oil or water vapor, which are then removed by the vacuum pumping system. This effectively "bakes out" the furnace, leaving it exceptionally clean and ready for a sensitive process.

Common Pitfalls and What to Avoid

How you clean is as important as the cleaning itself. A single mistake can cause significant damage or compromise future operations.

The Danger of Using Solvents

Never use liquid cleaning agents or volatile solvents inside the furnace chamber. Any residual solvent will become a massive source of outgassing in the next cycle, contaminating the vacuum pumps and the workpiece.

Damaging Sensitive Components

Be extremely cautious when cleaning around fragile components. Graphite insulation is brittle and can be easily damaged. Molybdenum heating elements can become brittle after use. Avoid using wire brushes or excessive force that could cause mechanical damage.

Neglecting Associated Systems

A clean chamber is only part of the solution. As noted in standard maintenance checks, you must also inspect the vacuum pump oil for contamination. Dirty oil will have a higher vapor pressure, limiting the ultimate vacuum your system can achieve, regardless of how clean the chamber is.

Making the Right Choice for Your Goal

Your cleaning frequency and intensity should match your specific operational needs. A one-size-fits-all approach is inefficient.

- If your primary focus is running clean processes (e.g., annealing, tempering): A routine schedule of inspection and light mechanical cleaning, with less frequent burn-off cycles, is likely sufficient.

- If you run processes with high contamination potential (e.g., vacuum carburizing, brazing, processing oily parts): Implement a strict and frequent cleaning schedule, including a mandatory burn-off cycle between sensitive loads or after a set number of runs.

- If you are experiencing slow pump-down times or poor vacuum levels: A thorough chamber cleaning and burn-off cycle should be your immediate first step, as outgassing from internal contamination is the most probable cause.

Ultimately, treating your vacuum furnace's cleanliness as an integral part of the process itself is the key to achieving consistent, high-quality results.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| Initial Inspection | Visual check for soot, oil films, and debris. | Identify sources of contamination. |

| Mechanical Cleaning | Use HEPA vacuum and soft brushes to remove loose and adhered contaminants. | Eliminate physical debris without damaging components. |

| Fixture Cleaning | Remove and clean grids, baskets, and fixtures separately. | Isolate heavy contamination from the main chamber. |

| Dry Run-Out (Burn-Off) | Run empty furnace at high temperature under vacuum. | Vaporize microscopic contaminants for a deep clean. |

Maximize your vacuum furnace's performance and lifespan with KINTEK's expertise. Our specialized lab equipment and consumables are designed to support your maintenance needs, ensuring contamination-free processes and consistent, high-quality results. Contact our team today to discuss how we can help you optimize your thermal processing operations.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- What are the problems with heat treatment? Avoid Distortion, Cracking, and Surface Defects

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What are the safety precautions during heat treatment? A Guide to Managing Extreme Heat, Gases & Hazards

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space