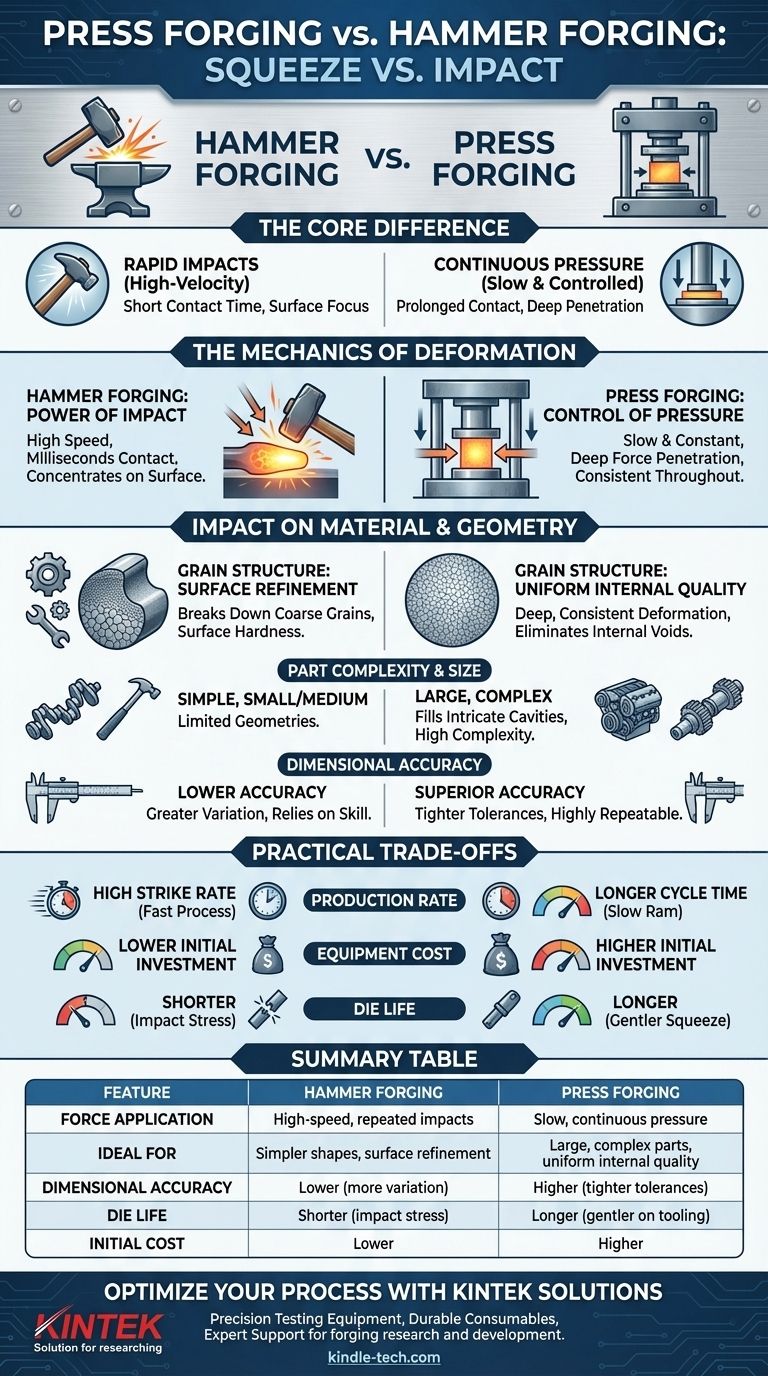

At its core, the difference between press forging and hammer forging lies in how force is applied to the workpiece. Hammer forging delivers a series of rapid, high-velocity impacts, similar to a blacksmith's hammer. In contrast, press forging applies a slow, continuous, and controlled pressure to squeeze the metal into shape.

While both methods shape metal through plastic deformation, the choice between them is a critical engineering decision. Hammer forging is defined by high-speed impact and is ideal for simpler shapes and surface refinement, whereas press forging uses slow, penetrating pressure, making it superior for large, complex parts that demand uniform internal quality.

The Mechanics of Deformation: Squeeze vs. Impact

The fundamental difference in force application dictates every other aspect of the process, from the material's resulting grain structure to the final part's complexity and cost.

Hammer Forging: The Power of Impact

Hammer forging utilizes a die that strikes the workpiece at high speed. This transfers a massive amount of kinetic energy in a very short duration.

The contact time between the hammer die and the hot metal is extremely brief, measured in milliseconds. This minimizes heat transfer from the workpiece to the die, keeping the core of the part hotter for longer.

However, the energy from the impact tends to concentrate on the surface of the workpiece. This can result in a less uniform deformation throughout the material's cross-section.

Press Forging: The Control of Pressure

Press forging, using either a mechanical or hydraulic press, is a process of controlled squeezing. The press ram moves at a much slower, constant speed, applying full pressure throughout its stroke.

This prolonged contact time allows the force to penetrate deep into the material. The slow application ensures the deformation is consistent from the surface to the very core of the workpiece.

This method provides exceptional control over the final shape and the material's internal grain flow.

Impact on Material Properties and Geometry

The "squeeze vs. impact" distinction directly influences the quality, shape, and precision of the final forged component.

Grain Structure and Internal Quality

Hammer forging is effective at refining the grain structure on and near the surface of the part. The rapid impacts break down coarse grains, improving surface hardness and fatigue resistance.

Press forging creates a much more uniform and fine-grained microstructure throughout the entire volume of the component. This deep, consistent deformation is critical for high-performance, stress-critical parts like turbine disks or aerospace structural components, as it eliminates internal voids and ensures predictable mechanical properties.

Achievable Part Complexity and Size

Hammer forging is typically used for small to medium-sized parts with relatively simple geometries, such as hand tools, crankshafts, and connecting rods.

Press forging excels at producing very large and geometrically complex parts. The slow, controlled pressure allows the metal to flow more completely into intricate die cavities, enabling the creation of components that are impossible to form with a hammer.

Dimensional Accuracy and Tolerances

Press forging offers superior dimensional accuracy and the ability to hold tighter tolerances. The controlled force and speed of the press result in a highly repeatable process.

Hammer forging is more reliant on operator skill and the energy of each blow, which can vary. This leads to greater dimensional variation in the final parts, often requiring more extensive secondary machining.

Understanding the Practical Trade-offs

Choosing a process is not just about material science; it's also a decision based on economics, production volume, and operational constraints.

Production Rate vs. Cycle Time

Hammer forging has a very high strike rate, making the process itself very fast. For simpler parts, this can lead to a higher overall production rate.

Press forging has a longer cycle time per part due to the slow movement of the ram. However, modern automated presses can still achieve high throughput for suitable components.

Equipment Cost and Investment

Hammer forging equipment is generally less expensive, requires a simpler foundation, and represents a lower initial capital investment.

Hydraulic and mechanical presses, especially those with high tonnage ratings, are massive, complex machines that are significantly more expensive to purchase, install, and maintain.

Die Life and Maintenance

The intense, repeated impacts of a forging hammer cause significant wear and stress on the dies, resulting in a shorter die life and higher tooling replacement costs.

The controlled squeeze of a press is much gentler on the tooling. This leads to longer die life and reduced maintenance, which can offset the higher initial equipment cost over the long term.

Making the Right Choice for Your Application

Selecting the correct forging process requires aligning the method's capabilities with your component's specific engineering and business requirements.

- If your primary focus is large, safety-critical components (e.g., aerospace landing gear, large industrial shafts): Choose press forging for its superior internal grain structure, uniformity, and void-free integrity.

- If your primary focus is high-volume production of smaller, simpler parts (e.g., hand tools, standard automotive components): Hammer forging is often the more cost-effective choice due to its speed and lower initial equipment cost.

- If your primary focus is extreme dimensional precision and complex geometry: Press forging provides the control necessary to achieve tight tolerances and fill intricate die cavities, minimizing final machining.

- If your primary focus is minimizing initial capital investment for a new operation: Hammer forging provides a lower barrier to entry for producing a range of standard forged parts.

Ultimately, the right process is the one that produces a part meeting all engineering specifications at the most effective total cost.

Summary Table:

| Feature | Hammer Forging | Press Forging |

|---|---|---|

| Force Application | High-speed, repeated impacts | Slow, continuous pressure |

| Ideal For | Simpler shapes, surface refinement | Large, complex parts, uniform internal quality |

| Dimensional Accuracy | Lower (more variation) | Higher (tighter tolerances) |

| Die Life | Shorter (due to impact stress) | Longer (gentler on tooling) |

| Initial Equipment Cost | Lower | Higher |

Optimize Your Metal Forming Process with KINTEK Solutions

Choosing between press forging and hammer forging is critical for achieving the right balance of part quality, cost, and performance. At KINTEK, we specialize in providing advanced lab equipment and consumables that support material testing and process development for forging applications. Whether you're researching material behavior, testing die designs, or optimizing production parameters, our reliable tools help you make data-driven decisions.

Let us help you enhance your forging operations:

- Precision Testing Equipment: Evaluate material properties and grain structure.

- Durable Consumables: Ensure consistent results in high-temperature forging simulations.

- Expert Support: Leverage our expertise to select the right tools for your R&D or quality control needs.

Contact us today to discuss how KINTEK's solutions can support your forging challenges and drive efficiency in your laboratory or production environment.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Lab Heat Press

People Also Ask

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes