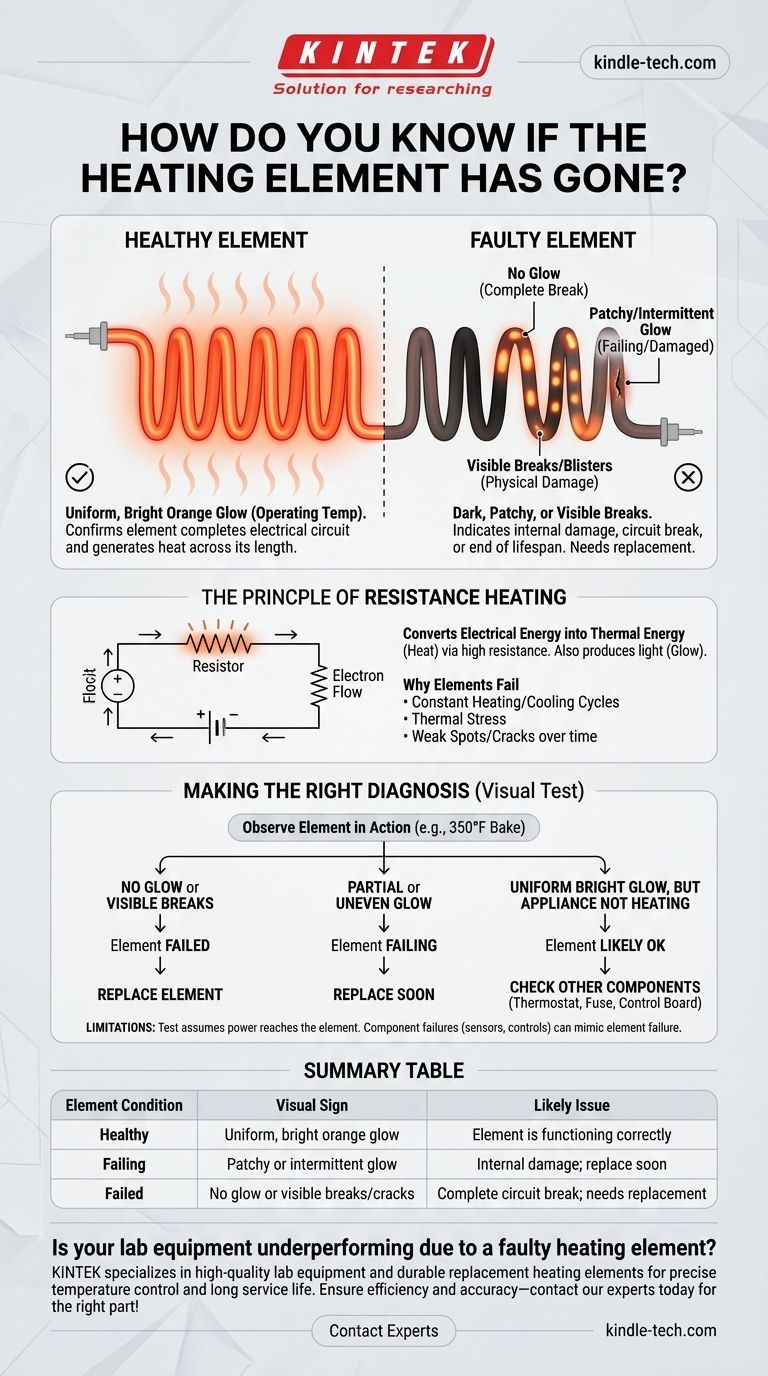

The most direct way to know if a heating element has failed is through a simple visual inspection. A healthy element will glow a consistent, bright orange when it reaches its operating temperature. If the element remains dark, only glows in patches, or shows any visible breaks or blisters, it is faulty and needs to be replaced.

A heating element is a simple component that works by converting electrical energy into heat. The visual "glow test" is the fastest way to confirm if the element is capable of completing this electrical circuit and generating heat across its entire length.

The Principle of Resistance Heating

How an Element Generates Heat

A heating element functions like a resistor. When an electric current is passed through it, the element's high resistance causes friction for the electrons, which converts electrical energy into thermal energy, or heat.

This process also produces light, which is why a functioning element glows.

Why Elements Fail

The constant cycle of extreme heating and cooling puts immense stress on the element's material. Over time, this can cause weak spots, cracks, or a complete break in the internal wiring, interrupting the electrical path.

Once the path is broken, the element can no longer generate heat.

Performing the Visual Diagnostic

The Glow Test

The simplest diagnostic is to observe the element in action. For an oven, you can set it to a bake setting of around 350°F (177°C) and wait for about ten minutes.

A fully functional element will emit a uniform, bright orange glow across its entire surface.

Identifying a Faulty Element

A failed or failing element will behave differently. Look for these key signs:

- No glow at all: This indicates a complete break in the circuit.

- Patchy or intermittent glow: If only certain spots turn orange, it means the element is damaged and will likely fail completely soon.

- Visible damage: Even when cold, inspect the element for any blisters, bubbles, or cracks on its surface.

Understanding the Limitations

The Test Is Not Always Conclusive

While the glow test is a reliable first step, it assumes the element is receiving power in the first place.

If the element doesn't glow, the fault could also lie with another component, such as a thermostat, fuse, or the appliance's control board, which may not be sending power to the element.

Component Quality and Lifespan

Heating elements are designed for specific temperature ranges. For example, standard resistance wire is suitable for temperatures up to 1200°C.

An element is a consumable part. Its failure is typically due to reaching the end of its natural service life through repeated use, not necessarily a defect in the appliance itself.

Making the Right Diagnosis

After performing the visual test, your next step depends on the result. Use these points to guide your decision.

- If you see no glow or visible breaks: The heating element is the most likely cause of the problem and should be replaced.

- If you see a partial or uneven glow: The element is failing and is the source of your heating issue; it needs to be replaced before it fails completely.

- If the element glows bright orange but the appliance still isn't heating correctly: The problem is likely with another part, such as a temperature sensor or controller, and requires further diagnosis.

Trusting a simple, direct observation is the most effective way to begin any technical diagnosis.

Summary Table:

| Element Condition | Visual Sign | Likely Issue |

|---|---|---|

| Healthy | Uniform, bright orange glow | Element is functioning correctly |

| Failing | Patchy or intermittent glow | Internal damage; replace soon |

| Failed | No glow or visible breaks/cracks | Complete circuit break; needs replacement |

Is your lab equipment underperforming due to a faulty heating element? KINTEK specializes in high-quality lab equipment and consumables, including durable replacement heating elements designed for precise temperature control and long service life. Ensure your laboratory's efficiency and accuracy—contact our experts today for a consultation and get the right part for your needs!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- What are the disadvantages of tungsten filament? Key Limitations in Lighting Technology

- What is the advantage of molybdenum? Unlock Superior High-Temperature Performance

- How does a graphite heater work? Achieve Extreme Temperatures with Unmatched Precision

- How do you check the temperature of a heating element? Choose the Right Tool for Accurate Results

- What are the specific temperature control requirements for high-precision thermocouples? Achieve ±0.3°C Precision

- Which element is best for heating? Match the Right Material to Your Application for Optimal Performance

- How does a resistive heating element work? Convert Electricity to Heat Efficiently