No, molybdenum disulfide is not used as a heating element. This is a common point of confusion due to its similar name to molybdenum disilicide (MoSi2), which is a premier material for high-power electric heating elements. Molybdenum disulfide's properties make it an excellent solid lubricant, not a material for generating resistive heat.

The critical difference lies in their chemistry and resulting high-temperature behavior. Molybdenum disilicide (MoSi2) forms a protective glass-like layer of silica (SiO2) when heated, allowing it to resist oxidation at extreme temperatures. Molybdenum disulfide (MoS2) is engineered for low friction, not heat generation.

The Premier Choice: Molybdenum Disilicide (MoSi2)

Molybdenum disilicide (MoSi2) is a refractory ceramic specifically engineered for high-temperature heating applications. It is the material of choice for the most demanding industrial furnaces.

Why It Excels at Extreme Temperatures

MoSi2 elements can operate at temperatures up to 1850°C (3360°F), far exceeding the capabilities of many other materials. This allows for processes like ceramic sintering, glass manufacturing, and semiconductor diffusion.

The Protective Silica Shield

The key to MoSi2's performance is its exceptional oxidation resistance. When heated, the silicon in the compound reacts with oxygen to form a thin, protective layer of silica (SiO2) on its surface.

This self-healing layer prevents the underlying material from degrading, enabling thousands of hours of continuous operation in air without deep oxidation.

Common Industrial Applications

Due to its consistent performance and long life, MoSi2 is a staple in several industries:

- Heat treatment furnaces

- Glass industry melting and processing

- Sintering of ceramic materials

- Semiconductor diffusion furnaces

Understanding Other Molybdenum Compounds

While MoSi2 is the top performer for high-heat applications, pure molybdenum and molybdenum disulfide serve entirely different purposes.

Pure Molybdenum (Mo) for Moderate Heat

Pure molybdenum is a refractory metal also used in heating elements, but for more moderate temperatures, typically in vacuum furnaces.

It offers excellent electrical conductivity and strength but becomes brittle above 1700°C (3100°F). It is well-suited for processes like brazing and hardening.

Molybdenum Disulfide (MoS2): A High-Performance Lubricant

Molybdenum disulfide (MoS2) is valued for its extremely low friction and high wear resistance. Its structure allows layers of the material to slide against each other with minimal force.

It is applied as a coating in demanding environments where traditional liquid lubricants would fail, such as in aerospace applications. Its properties are, in many ways, the opposite of what is required for a heating element.

Understanding the Trade-offs

While MoSi2 is an exceptional heating material, it is not without its limitations. Understanding its mechanical properties is crucial for proper furnace design and operation.

Hardness and Brittleness

Molybdenum disilicide is a very hard but brittle ceramic. It has a low impact strength, meaning it can crack or shatter if subjected to mechanical shock, especially when cold.

Deformation Under Load (Creep)

At very high operating temperatures, MoSi2 elements are prone to a phenomenon known as creep, where the material can slowly deform or sag under its own weight over time. This necessitates careful design of the element supports within a furnace.

Making the Right Choice for Your Goal

Selecting the correct molybdenum-based material is entirely dependent on your technical objective.

- If your primary focus is extreme-temperature heating (up to 1850°C) in air: Molybdenum disilicide (MoSi2) is the definitive choice for its unmatched oxidation resistance and performance.

- If your primary focus is moderate-temperature heating (up to 1700°C) in a vacuum: Pure molybdenum offers a durable and reliable solution for applications like vacuum furnace elements.

- If your primary focus is reducing friction and wear in a mechanical system: Molybdenum disulfide (MoS2) is the correct material, serving as a high-performance solid lubricant coating.

Ultimately, specifying the correct compound—disilicide for heat, disulfide for lubrication—is critical for the success of any high-performance engineering project.

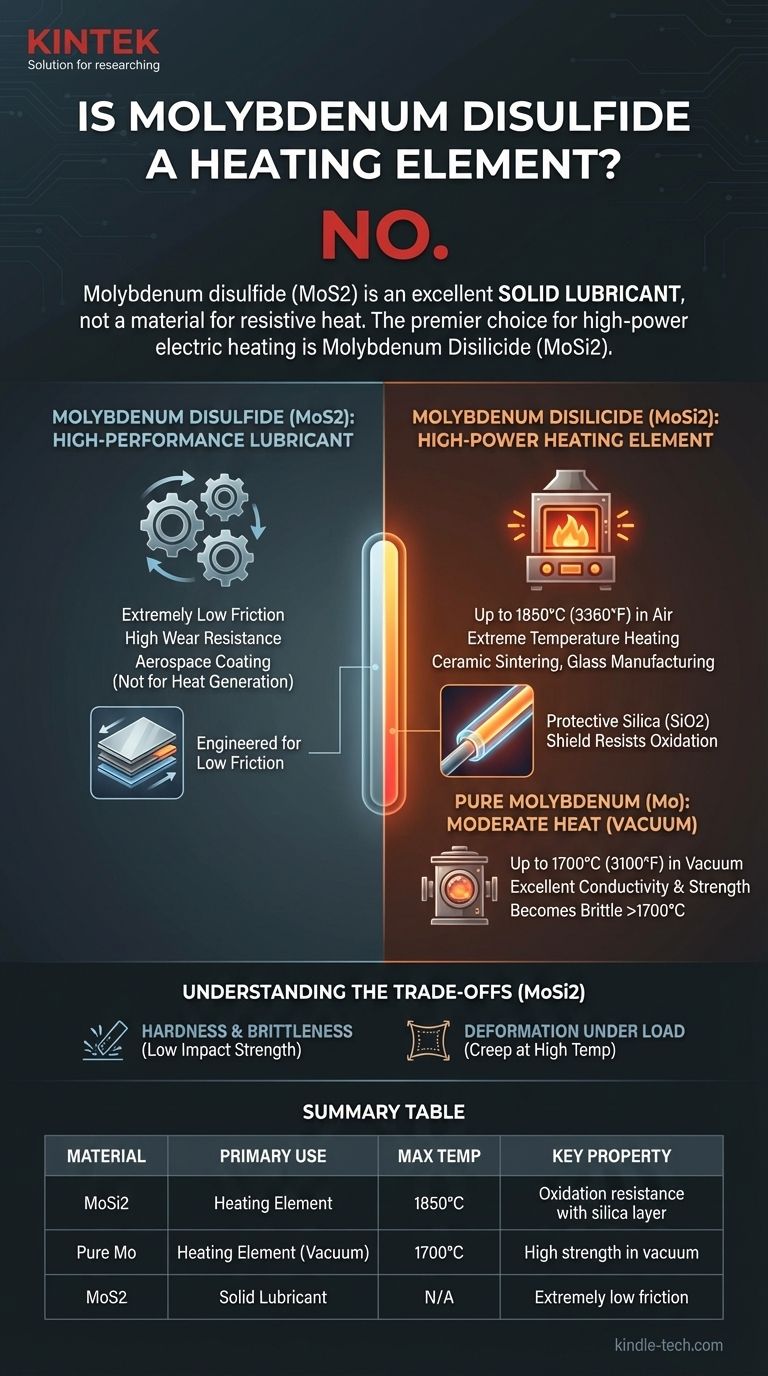

Summary Table:

| Material | Primary Use | Max Temperature | Key Property |

|---|---|---|---|

| Molybdenum Disilicide (MoSi2) | Heating Element | 1850°C (3360°F) | Oxidation resistance with silica layer |

| Pure Molybdenum (Mo) | Heating Element (Vacuum) | 1700°C (3100°F) | High strength in vacuum environments |

| Molybdenum Disulfide (MoS2) | Solid Lubricant | N/A | Extremely low friction and wear resistance |

Need the right high-temperature solution for your lab? KINTEK specializes in lab equipment and consumables, including molybdenum disilicide heating elements for demanding applications. Contact us today to enhance your furnace performance and achieve precise thermal processing!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Square Bidirectional Pressure Mold for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are the key properties of metallic heating elements in heat treatment furnaces?

- How do electric heating coils and PID controllers optimize bio-oil production? Achieve 500°C Precision for Peak Yield

- Why are separate thermocouples required for magnesium vacuum sublimation? Ensure Precision & Protect Your Equipment

- Why use SiC heating elements for Li2ZrO3-MgO synthesis at 1300°C? Achieve Precise Thermal Stability

- Are PTC heaters considered energy efficient and cheap to run? Save Costs with Self-Regulating Heating Technology

- What happens to tungsten when heated? Discover Its Extreme Heat Resistance and Unique Properties

- What are SiC components? Transform Your Power Electronics with Superior Efficiency and Density

- What is graphite heating? A Guide to Durable, High-Temp Industrial Furnace Solutions