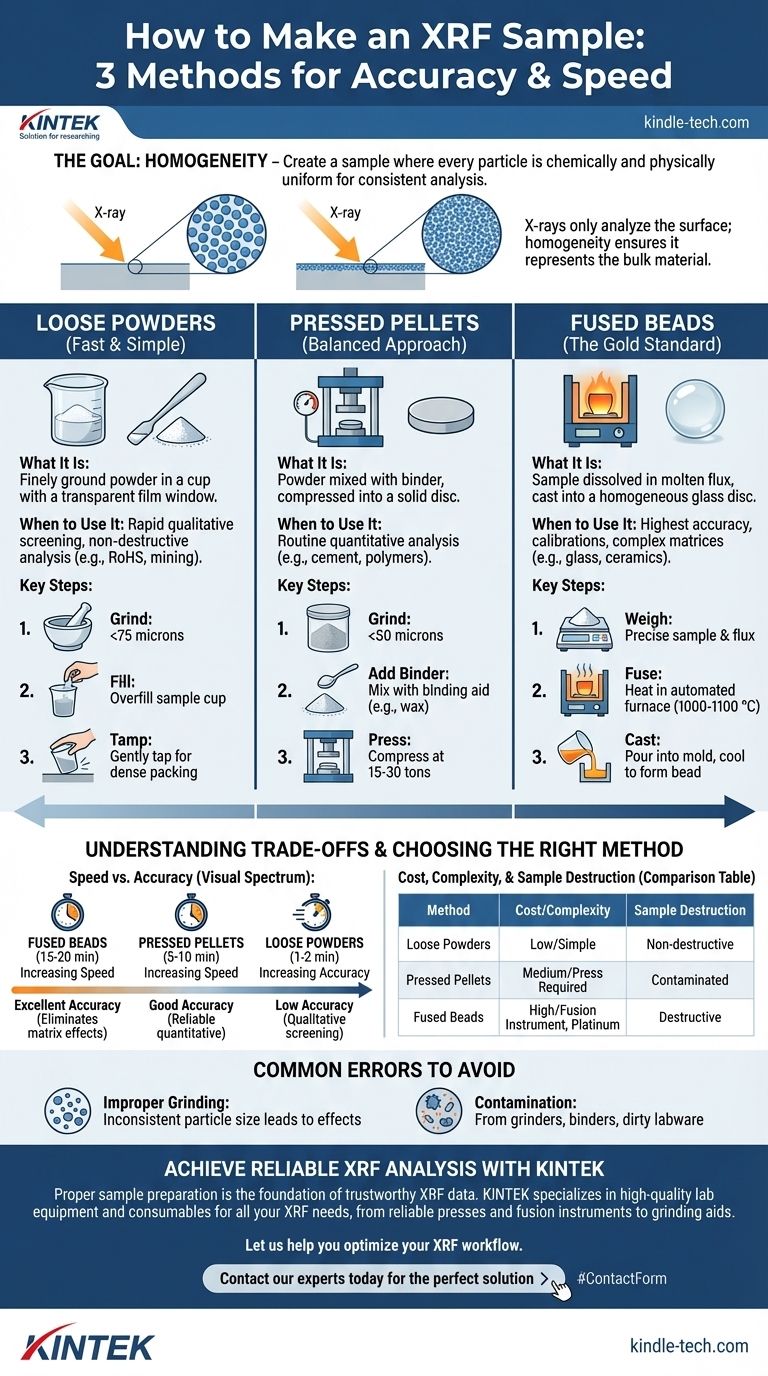

In essence, you create an XRF sample by preparing your material to be as homogeneous and representative as possible for analysis. The three primary methods, chosen based on your required accuracy and available time, are preparing loose powders, pressing the powder into a solid pellet, or fusing the material into a glass-like bead. Each method is designed to minimize physical and chemical errors that can compromise the quality of your results.

The single most important principle of XRF sample preparation is to create a sample that is physically and chemically homogeneous. The method you choose—loose powder, pressed pellet, or fused bead—is a direct trade-off between speed and the ultimate accuracy of your analysis.

The Foundation: Why Sample Preparation is Critical

The quality of your XRF data is determined long before you place the sample into the analyzer. An X-ray beam only analyzes a very small and shallow portion of the sample surface. If that surface isn't a perfect representation of the bulk material, your results will be incorrect.

The Goal: Homogeneity

Homogeneity is the state where every particle in the sample is the same as every other particle in terms of size and composition. The goal of preparation is to get as close to this ideal as possible.

Without proper preparation, a coarse or poorly mixed sample can lead to wildly inconsistent results if you measure it multiple times.

The Enemy: Analytical Errors

Two main types of errors arise from poor sample preparation.

Particle size effects occur when larger particles in the sample emit less fluorescence than smaller particles of the same element, leading to under-reported results. Proper grinding is the only way to mitigate this.

Matrix effects are chemical interferences where the presence of one element affects the X-ray signal of another. This is a fundamental challenge that advanced preparation methods, like fusion, are designed to eliminate.

Method 1: Loose Powders

This is the simplest and fastest method of sample preparation.

What It Is

A finely ground powder is placed into a sample cup that has a thin, X-ray transparent film (like Mylar or Polypropylene) as a bottom window.

When to Use It

Use this method for rapid qualitative or semi-quantitative screening, situations where the sample cannot be destroyed, or when high accuracy is not the primary goal. It is common in applications like screening for hazardous elements (RoHS), mining, and environmental analysis.

Key Steps

- Grind: The material must be ground to a fine, consistent particle size (typically below 75 microns).

- Fill: Overfill the sample cup with the powder.

- Tamp: Gently tap the cup on a hard surface to ensure the powder is densely and evenly packed against the film window.

Method 2: Pressed Pellets

This method offers a significant improvement in accuracy and repeatability over loose powders.

What It Is

A finely ground powder is mixed with a binding agent and then compressed under high pressure (typically 15-30 tons) to form a solid, durable disc.

When to Use It

This is the workhorse method for most routine quantitative analysis. It provides an excellent balance of accuracy, throughput, and cost for applications in cement, polymers, and industrial minerals.

Key Steps

- Grind: The sample must be ground to an extremely fine powder (ideally below 50 microns) to minimize particle size effects.

- Add Binder: A small, precise amount of grinding/binding aid (e.g., cellulose wax) is mixed with the sample.

- Press: The mixture is placed in a die and compressed in a hydraulic press to form a pellet with a perfectly flat, stable analytical surface.

Method 3: Fused Beads (The Gold Standard)

Fusion is the most complex method but provides the highest level of accuracy by eliminating most sources of error.

What It Is

The sample is dissolved in a molten lithium borate flux at high temperature (around 1000-1100 °C). This molten mixture is then cast into a mold to cool into a perfectly homogeneous glass disc, or "bead."

When to Use It

Use fusion when the highest accuracy is non-negotiable. This is the required method for creating calibrations, certifying materials, and performing process control in industries like glass, ceramics, metals, and geological research where matrix effects are severe.

Key Steps

- Weigh: A precise amount of sample and flux are weighed into a platinum crucible.

- Fuse: The crucible is heated in an automated fusion instrument until the sample completely dissolves into the flux. The machine agitates the mixture to ensure homogeneity.

- Cast: The molten glass is poured into a platinum mold and rapidly cooled to form the final bead.

Understanding the Trade-offs

Choosing a preparation method requires balancing competing priorities. There is no single "best" method for all situations.

Speed vs. Accuracy

This is the central trade-off.

- Loose Powders: Fastest (1-2 minutes), but least accurate and repeatable.

- Pressed Pellets: Good balance (5-10 minutes), offering reliable quantitative results.

- Fused Beads: Slowest (15-20 minutes), but provides the highest possible accuracy by eliminating physical and mineralogical effects.

Cost and Complexity

The required equipment and consumables vary significantly. Fusion requires a significant investment in an automated fusion machine, platinum labware, and expensive flux chemicals. Pressing requires a press and die set. Loose powders only require disposable cups.

Sample Destruction

Fusion is a completely destructive technique; the original sample cannot be recovered. Pressed pellets can sometimes be broken apart to recover the material, but it will be contaminated with binder. Loose powders are non-destructive and can be fully recovered.

Common Errors to Avoid

The most common mistake is improper grinding. A sample that is not ground finely enough will suffer from particle size effects, regardless of the subsequent method used. Another frequent error is contamination from grinders, binders, or dirty labware, which can introduce false elements into your analysis.

Choosing the Right Method for Your Goal

Your analytical objective dictates your preparation strategy.

- If your primary focus is rapid screening or sorting materials: Use loose powders for their speed and simplicity.

- If your primary focus is reliable, routine quantitative analysis: Use pressed pellets for a robust balance of accuracy, speed, and cost.

- If your primary focus is the highest possible accuracy, method development, or analyzing complex matrices: Use fused beads to eliminate errors and produce reference-quality data.

Ultimately, investing time in the correct sample preparation is the most effective way to ensure your analytical results are trustworthy and valuable.

Summary Table:

| Method | Key Feature | Best For | Accuracy | Speed |

|---|---|---|---|---|

| Loose Powders | Fast & simple | Qualitative screening, non-destructive analysis | Low | 1-2 min |

| Pressed Pellets | Balanced approach | Routine quantitative analysis (cement, polymers) | Good | 5-10 min |

| Fused Beads | Highest accuracy | Complex matrices, reference materials (glass, ceramics) | Excellent | 15-20 min |

Achieve Reliable and Accurate XRF Analysis with KINTEK

Proper sample preparation is the foundation of trustworthy XRF data. The method you choose directly impacts the quality of your results. Whether you need the speed of loose powders for screening, the robust balance of pressed pellets for routine work, or the unparalleled accuracy of fused beads for complex materials, having the right equipment is crucial.

KINTEK specializes in high-quality lab equipment and consumables for all your XRF sample preparation needs. We provide the reliable presses, fusion instruments, grinding aids, and consumables that laboratories depend on for consistent, high-integrity results.

Let us help you optimize your XRF workflow. Contact our experts today to discuss your specific application and find the perfect preparation solution for your laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the limitation of XRF? Understanding the Key Constraints for Accurate Analysis

- What happens if you don't change hydraulic oil? Avoid Costly Equipment Failure and Downtime

- How hot is too hot for hydraulics? Protect Your System from Costly Heat Damage

- Why must pressing equipment for metal nanopowders be equipped with vacuum or atmospheric protection? Prevent Oxidation

- Why must a hydraulic press apply 720 MPa for solid-state batteries? Achieve Optimal Ion Path & Density

- How much does it cost to build a hydraulic press? A DIY Guide to Budgeting for Power and Safety

- Why is a laboratory hydraulic press used during the solid-state preparation of TiO2 catalysts? Optimize Doping Now

- What kind of press is used for forging? The Definitive Guide to Hydraulic Forging Presses