Making a sintered metal part is a powder metallurgy process that transforms loose metal powder into a solid, functional component. It involves two primary stages: first, compacting the metal powder into a preliminary shape called a "green compact," and second, heating that compact in a controlled-atmosphere furnace to a temperature below its melting point, causing the individual particles to fuse together.

The core principle of sintering is not to melt the material, but to use heat and pressure to induce atomic diffusion between powder particles. This process bonds them into a solid mass, systematically reducing internal pores and creating a strong, dense component with specific, engineered properties.

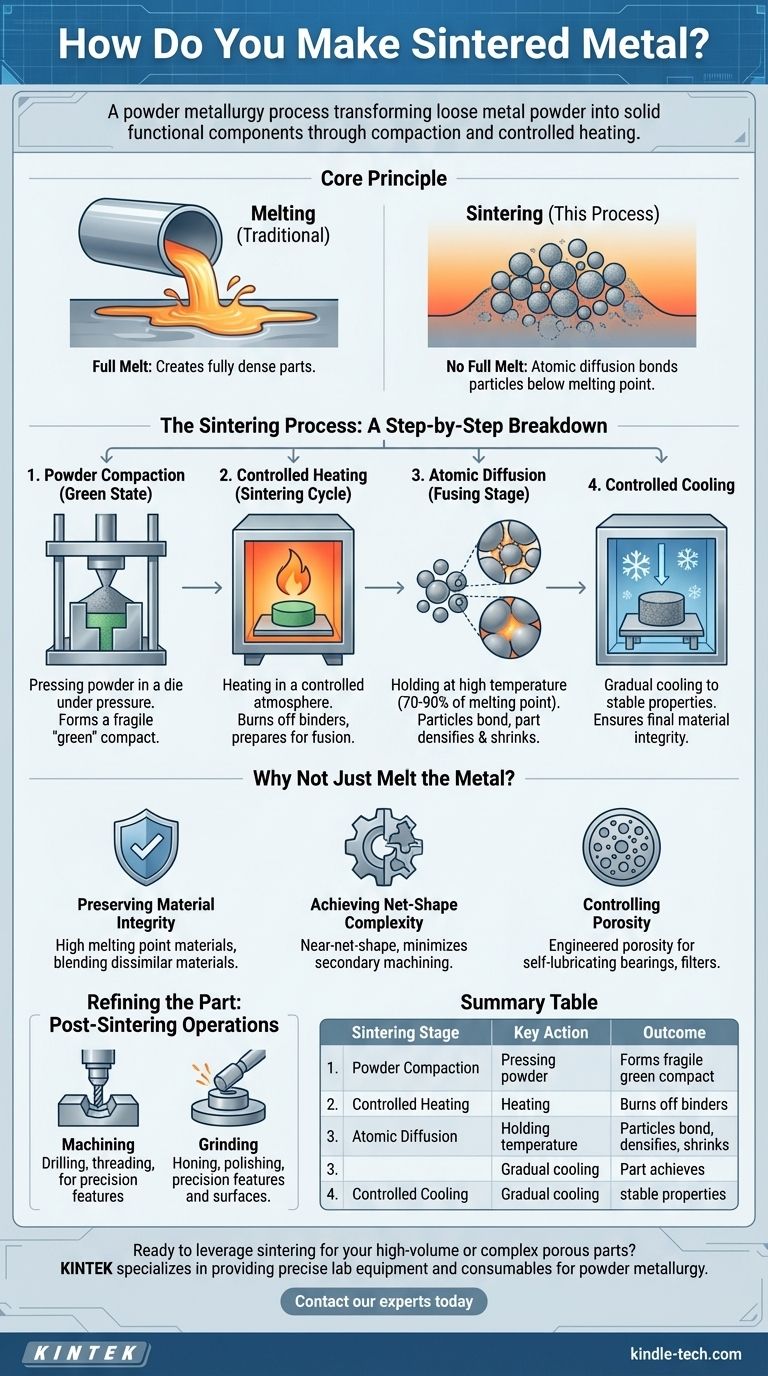

The Sintering Process: A Step-by-Step Breakdown

Sintering is more than just heating a powder; it's a precise thermal treatment designed to achieve a specific outcome. Each stage plays a critical role in the final part's integrity.

Step 1: Powder Compaction (The "Green" State)

Before heating, the chosen metal powder is poured into a die and compacted under immense pressure.

This initial pressing forms the material into the desired shape, known as a green compact or green body. While it holds its shape, this component is fragile and has low mechanical strength.

Step 2: Controlled Heating (The Sintering Cycle)

The green compact is placed into a furnace with a controlled atmosphere to prevent oxidation. The temperature is gradually increased.

During this initial heating phase, any residual lubricants or binders from the compaction stage are burned off at lower temperatures.

Step 3: Atomic Diffusion (The Fusing Stage)

As the part reaches the target sintering temperature—typically 70-90% of the metal's melting point—a crucial transformation occurs at the microscopic level.

The individual powder particles begin to diffusion-bond where they touch. The contact area between particles grows, pulling them closer together and reducing the volume of the pores between them.

This fusion results in densification, where the part shrinks slightly as its porosity decreases and its overall density and strength dramatically increase.

Step 4: Controlled Cooling

After being held at the sintering temperature for a specific duration, the newly solidified part is cooled in a controlled manner. This ensures it achieves its final, stable material properties without introducing thermal stress.

Why Not Just Melt the Metal?

Understanding why sintering is chosen over traditional casting or melting reveals its unique engineering advantages. The process is intentionally performed below the material's melting point.

Preserving Material Integrity

By avoiding a full melt, sintering allows for the creation of parts from materials with very high melting points. It also enables the blending of different materials that would not be possible through melting, such as metals and ceramics.

Achieving Net-Shape Complexity

Sintering is a net-shape or near-net-shape process. The initial compaction die is built to the precise dimensions of the final part, minimizing the need for wasteful secondary machining.

Controlling Porosity

Unlike melting, which creates a fully dense part, sintering allows for precise control over the final porosity. This is a critical feature for applications like self-lubricating bearings or filters, where interconnected pores are a design requirement.

Common Pitfalls and Considerations

While powerful, the sintering process has inherent characteristics that must be understood to be properly managed.

Inherent Porosity

Unless secondary operations are performed, most sintered parts retain a small amount of residual porosity. This can be a limiting factor for applications requiring the absolute highest levels of tensile strength or fatigue resistance.

Tooling Costs and Design Limitations

The hard tooling (dies and punches) required for compaction can be complex and expensive to produce. This makes the process most cost-effective for high-volume production runs.

The Need for Secondary Operations

While a near-net-shape process, sintering often cannot produce the ultra-fine tolerances or specific features required for a finished component. Post-processing is a common and expected part of the workflow.

Refining the Part: Post-Sintering Operations

To meet final specifications, sintered parts frequently undergo secondary manufacturing steps.

Machining for Precision Features

Standard machining operations are used to add features that cannot be formed during compaction. This includes processes like threading, drilling, boring, milling, and tapping.

Grinding for Surface and Dimension

For applications requiring high-precision surfaces or tight dimensional accuracy, grinding processes are employed. These include honing, lapping, and polishing to achieve the final desired finish.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on your project's primary objective. Sintering offers a distinct set of capabilities that make it ideal for specific applications.

- If your primary focus is high-volume production of complex parts: Sintering is an excellent choice for its ability to create intricate shapes with minimal material waste and high repeatability.

- If your primary focus is creating components with controlled porosity: Sintering is one of the few processes that allows you to engineer the density of a part, making it essential for filters or self-lubricating bearings.

- If your primary focus is absolute maximum strength and zero porosity: You may need to consider secondary densification steps after sintering or evaluate alternative processes like forging or precision casting.

By understanding sintering as a complete process from powder to finished part, you can effectively leverage its unique advantages in manufacturing.

Summary Table:

| Sintering Stage | Key Action | Outcome |

|---|---|---|

| 1. Powder Compaction | Pressing powder in a die | Forms a fragile "green" compact |

| 2. Controlled Heating | Heating in a furnace below melting point | Burns off binders, prepares for fusion |

| 3. Atomic Diffusion | Holding at high temperature | Particles bond, part densifies and shrinks |

| 4. Controlled Cooling | Gradual cooling in controlled atmosphere | Part achieves final, stable properties |

Ready to leverage sintering for your high-volume or complex porous parts? KINTEK specializes in providing the precise lab equipment and consumables essential for advanced powder metallurgy processes. Whether you're developing new materials or optimizing your sintering cycle, our expertise and reliable products support your laboratory's success. Contact our experts today to discuss how we can enhance your sintering capabilities and help you achieve superior results.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification