The fundamental method for measuring a leak is to quantify the volume or mass of a substance lost over a specific period. For a simple liquid leak, this can be as direct as collecting the dripping fluid in a measuring cup and timing it. For gases or complex systems, this involves using specialized instruments that measure changes in pressure, flow, or acoustic signals to calculate a precise leak rate.

Measuring a leak is not just about confirming its existence; it is about translating an unknown problem into a quantifiable rate. This rate allows you to assess the leak's impact on cost, safety, and operational integrity, providing the objective data needed to make sound engineering and business decisions.

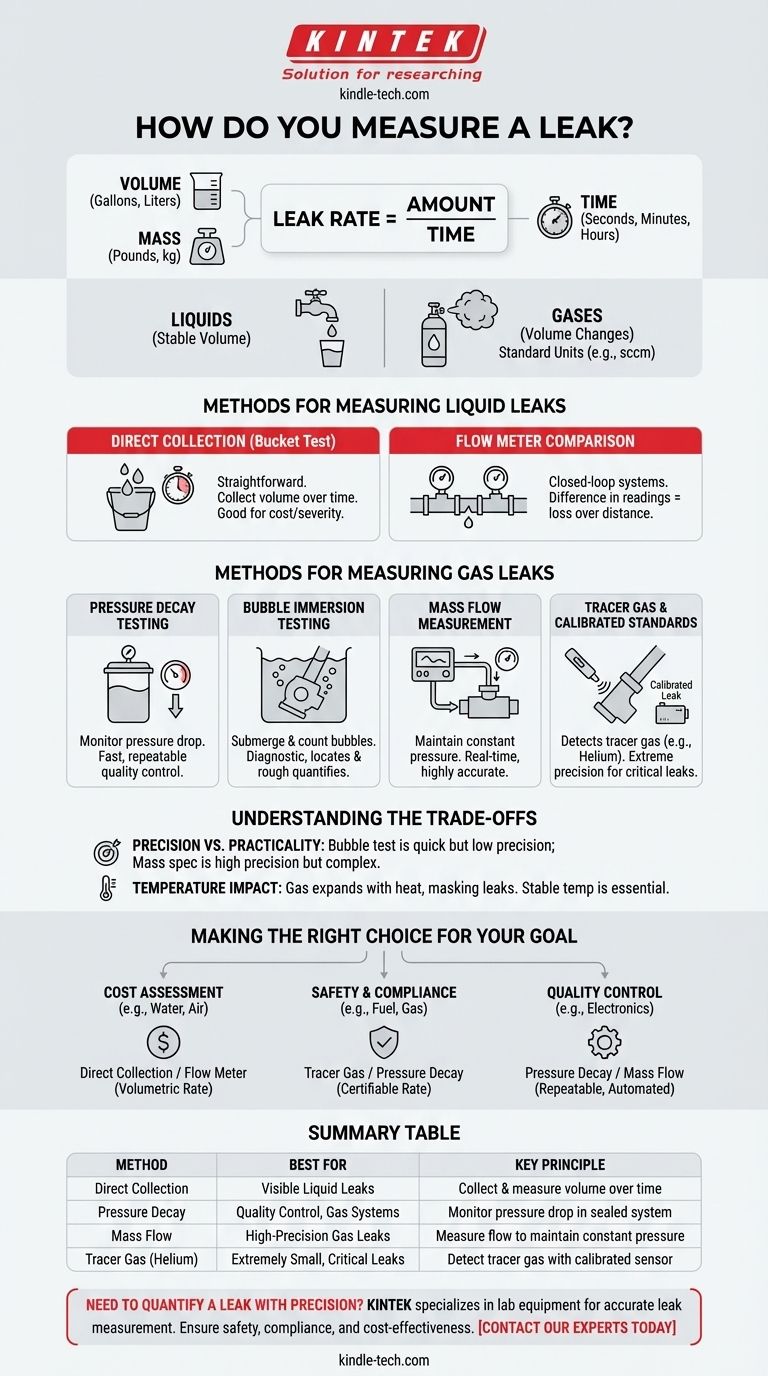

Foundational Principles of Leak Measurement

The Core Equation

At its heart, every leak measurement seeks to solve a simple equation: Leak Rate = Amount of Substance / Time.

The "Amount of Substance" can be volume (gallons, liters, cubic centimeters) or mass (pounds, kilograms). The "Time" is whatever interval you measure over (seconds, minutes, hours).

The challenge lies in accurately capturing the "Amount of Substance," especially when dealing with invisible gases or very slow leaks.

Absolute vs. Standard Conditions

For liquids, volume is relatively stable. For gases, volume changes dramatically with temperature and pressure.

Therefore, gas leak rates are often expressed in standard units, like "standard cubic centimeters per minute" (sccm). This converts the measurement to a baseline condition (e.g., 0°C and 1 atm), allowing for accurate comparisons regardless of the current environment.

Methods for Measuring Liquid Leaks

Direct Collection (The "Bucket Test")

This is the most straightforward method. Place a calibrated container under the leak and use a stopwatch to time how long it takes to collect a specific volume.

From this, you can easily calculate a rate, such as gallons per hour or liters per minute. While simple, it is highly effective for assessing the cost and severity of visible plumbing or equipment leaks.

Flow Meter Comparison

In a closed-loop system, you can install a flow meter before and after a suspected leaking section. The difference in the readings between the two meters indicates the volume of liquid being lost over that distance.

This method is useful for continuous monitoring of critical pipelines where direct collection is not feasible.

Methods for Measuring Gas Leaks

Pressure Decay Testing

This is an industry-standard method for quality control. The part or system is filled with a gas (often air or nitrogen) to a specified pressure, and the supply valve is closed.

An instrument then monitors the system's pressure over time. The rate of pressure drop is used to calculate the leak rate, often expressed in sccm. This test is fast, clean, and highly repeatable.

Bubble Immersion Testing

This method provides both location and a rough quantification. The pressurized part is submerged in a liquid, typically water.

The technician counts the number of bubbles released per minute. By estimating the average bubble size, you can approximate a volumetric leak rate. It is less precise than pressure decay but excellent for diagnostics.

Mass Flow Measurement

This highly accurate method connects a mass flow controller to a leaking part. The controller automatically feeds gas into the part to keep the internal pressure perfectly constant.

The amount of gas the controller must supply to maintain that pressure is exactly equal to the amount of gas leaking out. This provides a direct, real-time measurement of the leak rate.

Tracer Gas and Calibrated Standards

For detecting extremely small leaks, a tracer gas like helium is used. A detector, such as a helium mass spectrometer, "sniffs" the exterior of the part.

To quantify the leak, the detector's reading is compared against a calibrated leak standard—a device with a known, certified micro-leak. This allows the instrument to translate its signal into a precise rate, such as 1x10⁻⁶ sccm.

Understanding the Trade-offs

Precision vs. Practicality

A simple bubble test is immediate and requires minimal equipment but offers low precision. A mass spectrometer offers incredible precision but is expensive and requires a controlled setup.

The required precision depends entirely on the application. A water drip can be measured with a cup, but a medical implant's seal requires certified, high-precision testing.

The Impact of Temperature

For gas leak testing, temperature is a critical variable. If a sealed part heats up during a pressure decay test, the gas inside will expand, potentially masking the pressure drop from a leak.

Stable ambient temperatures are essential for accurate pressure decay and mass flow measurements. Any calculation must account for temperature fluctuations to avoid false results.

Making the Right Choice for Your Goal

- If your primary focus is cost assessment (e.g., a water or compressed air leak): Use direct collection or flow meter comparison to get a clear volumetric rate that can be translated directly into dollars wasted.

- If your primary focus is safety and compliance (e.g., a fuel or natural gas line): Use a tracer gas detector with a calibrated standard or a pressure decay test to get a certifiable, numeric leak rate that proves compliance with safety regulations.

- If your primary focus is manufacturing quality control (e.g., a sealed electronic enclosure): Standardize on pressure decay or mass flow testing for its high repeatability, speed, and ability to be automated for 100% inspection.

By moving from simple detection to precise measurement, you transform a vague problem into a solved one.

Summary Table:

| Method | Best For | Key Principle |

|---|---|---|

| Direct Collection | Visible liquid leaks | Collect and measure volume over time |

| Pressure Decay | Quality control, gas systems | Monitor pressure drop in a sealed system |

| Mass Flow | High-precision gas leaks | Measure gas flow needed to maintain constant pressure |

| Tracer Gas (Helium) | Extremely small, critical leaks | Detect a specific tracer gas with a calibrated sensor |

Need to quantify a leak with precision and reliability? KINTEK specializes in lab equipment and consumables, providing the precise instruments—from flow meters to gas analyzers—that laboratories rely on for accurate leak measurement. Ensure your processes are safe, compliant, and cost-effective. Contact our experts today to find the right solution for your laboratory's needs.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Why is a high-vacuum pumping system necessary during the gas-phase hydrogenation of Zr1Nb alloys? Ensure Material Purity

- Can vacuum tubes be rebuilt? A Guide to Restoring High-Power Industrial Tubes

- What is a vacuum heat treatment? Achieve Pristine, High-Performance Metal Parts

- What is vacuum carburizing? Achieve Superior Hardening with Precision & Speed

- Is brazing flux different to soldering flux? A Guide to Choosing the Right Chemical for Your Joint

- What's the difference between brazing and braze welding? Mastering Joint Strength & Application

- What metals Cannot be brazed? Understanding the Challenges of Low Melting Points and Reactive Oxides

- What is the role of a vacuum drying oven in the casting process of PEO-based polymer electrolyte membranes?