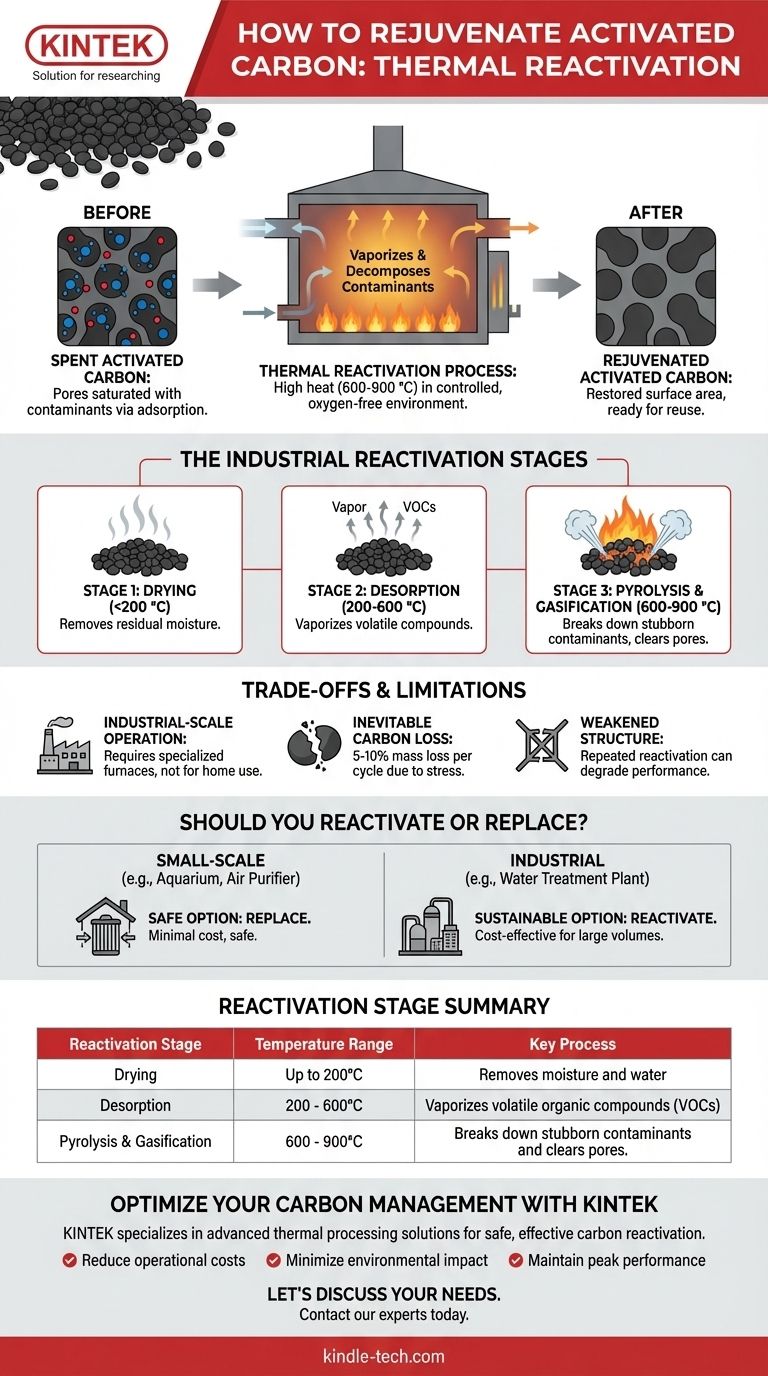

To rejuvenate activated carbon, you must use a process called thermal reactivation. This involves heating the spent carbon to extremely high temperatures, typically between 600 and 900 °C, within a controlled, oxygen-free environment. This intense heat vaporizes and decomposes the contaminants that have clogged the carbon's pores, effectively cleaning it and restoring its ability to adsorb new impurities.

While activated carbon can be rejuvenated, the process requires specialized industrial furnaces and is not a do-it-yourself task. For nearly all consumer or small-scale applications, replacing the carbon is the only practical, safe, and cost-effective option.

The Principle Behind Reactivation

How Adsorption Works

Activated carbon works because it has a vast internal network of microscopic pores, creating an enormous surface area. Contaminants in water or air get trapped within this network through a process called adsorption.

Reaching Saturation

Over time, these pores become completely filled with contaminants. At this point, the carbon is considered "spent" or "saturated" and can no longer effectively purify its surroundings.

The Thermal Solution

Thermal reactivation reverses this process. The extreme heat breaks the physical and chemical bonds holding the adsorbed pollutants. The controlled, oxygen-starved atmosphere is critical; it ensures the contaminants and carbonized residue are burned off without allowing the activated carbon itself to combust.

The Industrial Reactivation Process

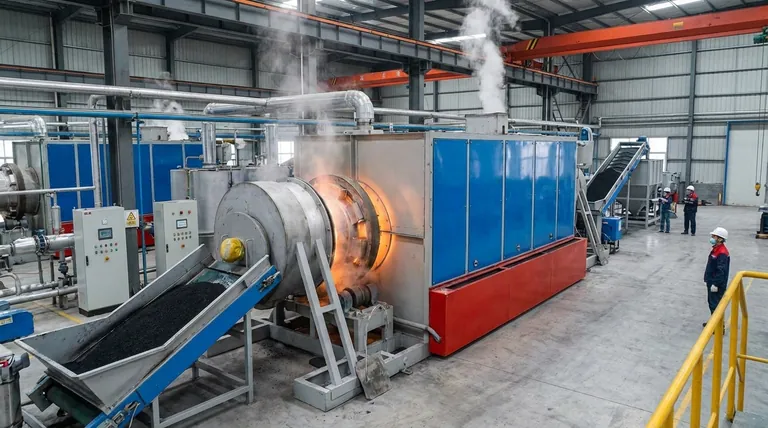

Reactivating carbon isn't a single step but a multi-stage process performed in large rotary kilns or furnaces.

Stage 1: Drying (Up to 200 °C)

The first phase involves gently heating the spent carbon to remove any residual water and moisture trapped within its porous structure.

Stage 2: Desorption (200 - 600 °C)

As the temperature increases, more volatile organic compounds (VOCs) that were adsorbed onto the carbon are vaporized and driven off.

Stage 3: Pyrolysis and Gasification (600 - 900 °C)

This is the core reactivation step. The remaining, more stubborn organic contaminants are broken down (pyrolyzed) into elemental carbon char. A controlled agent like steam is then introduced, which selectively gasifies this char residue, clearing out the original pore structure without significantly damaging the carbon granule itself.

Understanding the Trade-offs and Limitations

It's an Industrial-Scale Operation

Reactivation cannot be done in a conventional oven. The process requires highly specialized equipment that can safely manage extreme temperatures and control the internal atmosphere. Attempting this at home is ineffective and a significant fire hazard.

Inevitable Carbon Loss

The reactivation process is not perfectly efficient. With each cycle, a small percentage (typically 5-10%) of the activated carbon's mass is lost due to thermal stress and abrasion.

Weakened Structure

Repeated reactivation can also gradually degrade the carbon's physical structure, making it more brittle and slightly less effective over time. For this reason, new carbon is often blended with reactivated carbon to maintain performance standards.

Should You Reactivate or Replace?

The right choice depends entirely on the scale of your operation and your access to specialized facilities.

- If you are a homeowner or small-scale user (e.g., for an aquarium or air purifier): Replacement is your only safe and practical option. The cost of new carbon is minimal compared to the industrial expense of reactivation.

- If you manage a large industrial or municipal facility (e.g., a water treatment plant): Thermal reactivation is often the most cost-effective and environmentally sustainable choice for managing tons of spent carbon.

Ultimately, understanding the distinction between industrial capability and consumer practicality is key to managing your activated carbon effectively.

Summary Table:

| Reactivation Stage | Temperature Range | Key Process |

|---|---|---|

| Drying | Up to 200°C | Removes moisture and water |

| Desorption | 200 - 600°C | Vaporizes volatile organic compounds (VOCs) |

| Pyrolysis & Gasification | 600 - 900°C | Breaks down stubborn contaminants and clears pores |

Optimize your activated carbon management with KINTEK.

Whether you're running a large-scale water treatment plant or an industrial purification process, efficient handling of spent activated carbon is crucial for cost savings and sustainability. KINTEK specializes in advanced thermal processing solutions, including industrial furnaces and kilns designed for safe, effective carbon reactivation.

Our expertise helps you:

- Reduce operational costs by reactivating carbon instead of frequent replacement

- Minimize environmental impact through sustainable waste management

- Maintain peak performance with reliable, high-temperature equipment

Let’s discuss your needs. Contact our experts today to explore tailored solutions for your laboratory or industrial requirements.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- How to regenerate activated carbon? Master the 3-Stage Thermal Process for Cost Savings

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- What are the principles of a rotary kiln? Master the Mechanics of High-Temperature Processing

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process