At its core, a hydraulic press works by using a confined fluid to multiply force. It operates on a fundamental principle of physics known as Pascal's Law, allowing a small effort applied to a small piston to generate a massive force on a larger piston.

The central concept is force multiplication. By applying pressure to an incompressible fluid, the same pressure is transmitted to a second, larger piston. Because this larger piston has a greater surface area, the resulting force is proportionally magnified.

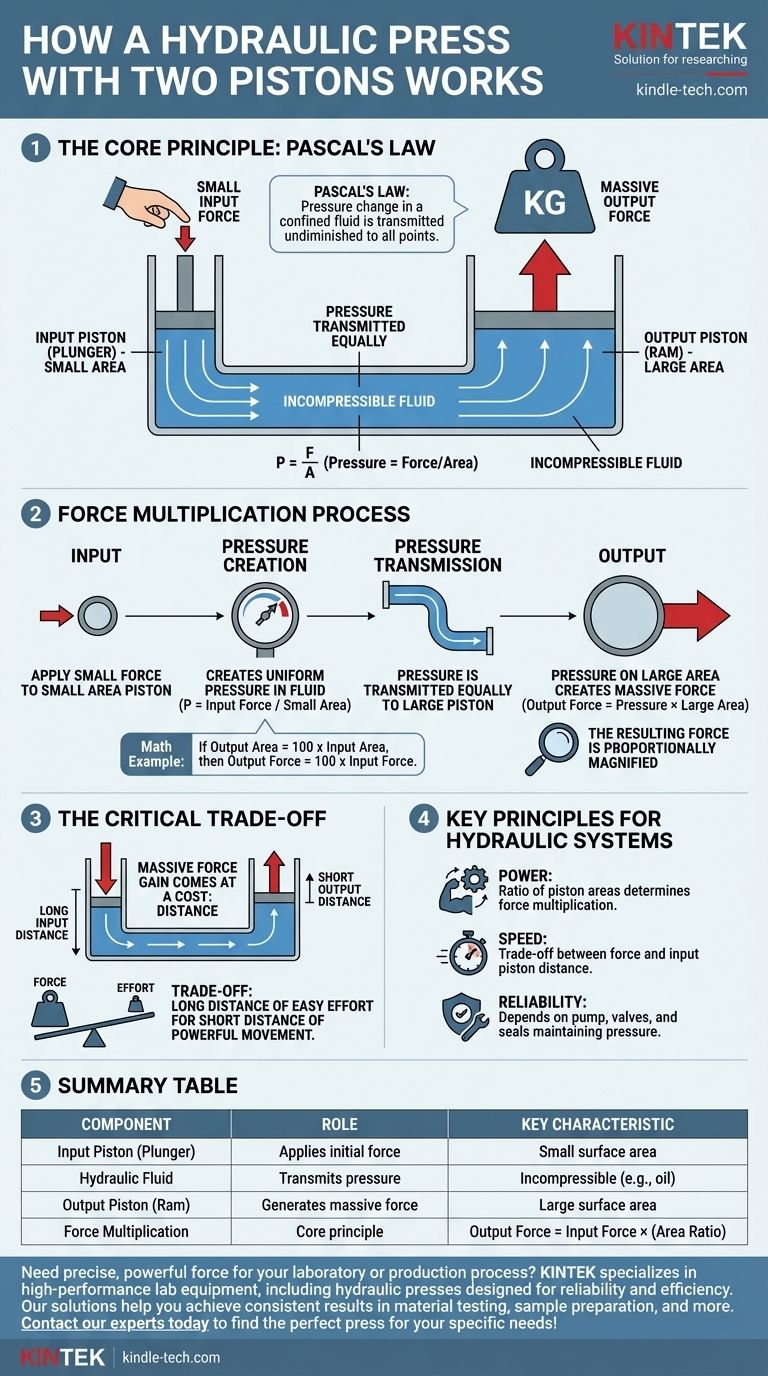

The Core Principle: Pascal's Law

Pascal's Law is the scientific foundation of all hydraulic systems. Understanding it is key to understanding how the press generates immense power.

A Confined, Incompressible Fluid

A hydraulic press uses a fluid, typically oil, that is incompressible. This means it doesn't get squeezed into a smaller volume under pressure.

When you push on this fluid, it doesn't absorb the force by compressing. Instead, it instantly transmits that force to every other part of the system.

Pressure is Transmitted Equally

Pascal's Law states that a change in pressure at any point in a confined fluid is transmitted undiminished to all points throughout the fluid.

Think of it as a perfectly rigid messenger. The pressure you create on one end is delivered equally and instantly to the other end.

How Two Pistons Create Force Multiplication

The magic of the hydraulic press happens in the relationship between the two pistons, which have different sizes.

The Input Piston (The Plunger)

A small input force is applied to a piston with a small surface area. This piston is often called the plunger.

This action creates pressure within the hydraulic fluid. The amount of pressure is calculated as Force divided by Area (P = F/A).

The Output Piston (The Ram)

This same pressure is transmitted through the fluid to a second, much larger piston, often called the ram.

Because the pressure is the same, but the area of this second piston is much larger, the resulting output force is also much larger.

The Math of Multiplication

The formula is Force = Pressure × Area. Since the pressure is constant throughout the system, if you increase the area, you must also increase the force.

If the output piston has 100 times the surface area of the input piston, it will produce 100 times the force. This is the essence of force multiplication.

Understanding the Trade-offs

This massive force gain does not come from nowhere. It involves a critical trade-off that is governed by the conservation of energy.

The Cost of Force: Distance

To achieve force multiplication, the small input piston must travel a much greater distance than the large output piston moves.

For example, to lift the large piston by one inch, you might have to push the small piston down by 100 inches. You are trading a long distance of easy effort for a short distance of powerful movement.

System Inefficiencies

In a perfect theoretical system, the transfer of energy is absolute. However, real-world systems lose some energy due to friction between the fluid and the pipes, as well as friction in the piston seals.

Modern presses use sophisticated pumps and electronic controls to manage pressure and minimize these inefficiencies, but the core principle remains the same.

Key Principles for Understanding Any Hydraulic System

Whether analyzing a simple shop press or a massive industrial machine, the fundamentals do not change.

- If your primary focus is power: The ratio of the pistons' surface areas is the single most important factor determining force multiplication.

- If your primary focus is speed: Recognize the trade-off between force and the distance the input piston must travel to move the output ram.

- If your primary focus is reliability: Look beyond the pistons to the components that support the system, such as the pump, valves, and seals, as these are critical for maintaining pressure.

Ultimately, the hydraulic press is a masterclass in using a simple physical law to create extraordinary power.

Summary Table:

| Component | Role | Key Characteristic |

|---|---|---|

| Input Piston (Plunger) | Applies initial force | Small surface area |

| Hydraulic Fluid | Transmits pressure | Incompressible (e.g., oil) |

| Output Piston (Ram) | Generates massive force | Large surface area |

| Force Multiplication | Core principle | Output Force = Input Force × (Area Ratio) |

Need precise, powerful force for your laboratory or production process? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for reliability and efficiency. Our solutions help you achieve consistent results in material testing, sample preparation, and more. Contact our experts today to find the perfect press for your specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the role of a laboratory hydraulic press in the formation of Li7P3S11? Optimize All-Solid-State Battery Density

- What role does a laboratory hydraulic press play in Fe-Cr-Al-Si alloy production? Mastering Powder Consolidation

- How do laboratory hydraulic presses and forming molds create 3D superlattice nanocatalysts? Enhance Material Density

- What is the difference between mechanical presses and hydraulic presses? A Guide to Choosing the Right Force

- Why is a laboratory hydraulic press required for Ti3SiC2 green bodies? Achieve Precision in Reaction Synthesis

- What is the primary function of an industrial vertical hydraulic press? Mastering Steel-Vanadium Composite Fabrication

- How does a laboratory hydraulic press contribute to room-temperature pressure sintering of sodium-based oxysulfide glass?

- What is the PSI rating of a hydraulic cylinder? The Critical Safety Limit for Your System