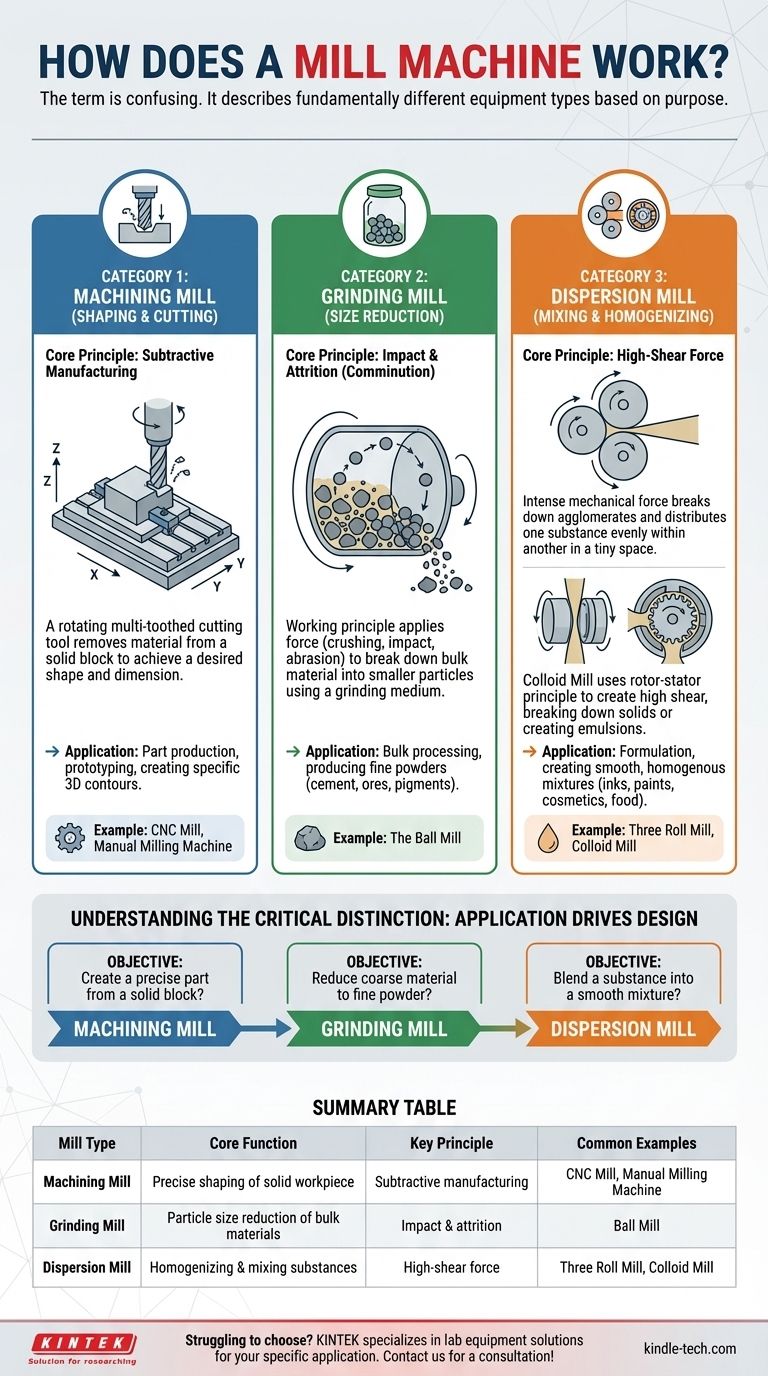

The term "mill machine" is often confusing because it describes several fundamentally different types of equipment. At a high level, a mill either uses a rotating cutter to precisely shape a solid workpiece through material removal, or it uses forces like impact and shear to grind, mix, or disperse bulk materials into smaller particles or a homogenous mixture.

The most critical distinction is the machine's purpose. A machining mill creates a specific shape from a single piece of material, while a grinding or mixing mill processes a bulk substance to change its physical properties, such as particle size or consistency.

Category 1: Mills for Shaping and Cutting (Machining)

This category refers to the classic milling machine found in machine shops for manufacturing parts. Its function is subtractive manufacturing.

The Core Principle: Subtractive Manufacturing

The fundamental goal is to remove material from a solid block or workpiece to achieve a desired shape and dimension. A sharp, multi-toothed cutting tool rotates at high speed, and either the tool or the workpiece is moved along precise paths to shave away material.

How a Milling Machine Works

A workpiece is securely clamped to a table. A rotating cutting tool, known as a mill or end mill, is brought into contact with the workpiece.

By moving the table (and workpiece) along the X and Y axes, and moving the tool or table along the Z axis, the rotating cutter removes material. This process can create a wide variety of features, including flat surfaces, slots, pockets, and complex 3D contours.

Category 2: Mills for Grinding and Size Reduction

These mills are designed not to shape an object, but to break down a bulk material into a smaller, more uniform particle size. This process is often called comminution.

The Core Principle: Impact and Attrition

The working principle is to apply force to a material to cause it to fracture. This is achieved by crushing, impact, or abrasion, often by using a hard grinding medium.

Example: The Ball Mill

A ball mill consists of a large hollow cylinder that rotates on a horizontal axis. The cylinder is partially filled with the material to be ground, along with a grinding medium—typically hard steel or ceramic balls.

As the cylinder rotates, the balls are lifted up the side and then cascade down, crushing and grinding the material through a combination of impact and abrasion. This is a common process for producing fine powders for products like cement, ores, and pigments.

Category 3: Mills for Mixing and Dispersion

This class of mills uses intense mechanical force to mix, disperse, or homogenize substances, particularly viscous liquids or pastes.

The Core Principle: High-Shear Force

The goal is to break down agglomerates (clumps of particles) and ensure one substance is evenly distributed within another. This is achieved by creating extremely high shear in the tiny space between two moving surfaces.

Example: The Three Roll Mill

This machine uses three horizontal rollers rotating in opposite directions at progressively higher speeds. Material is fed into the gap between the first two rollers.

The very narrow, adjustable gaps between the rollers create immense shear forces. As the material is transferred from one roller to the next, it is thinned, dispersed, and homogenized. This process is essential for manufacturing high-quality inks, paints, cosmetics, and chocolate.

Example: The Colloid Mill

A colloid mill operates on a rotor-stator principle. It has a high-speed rotor that spins with very tight clearance inside a stationary stator.

Material is fed into the mill and subjected to intense hydraulic shear as it passes through the narrow gap between the rotor and stator. This action effectively breaks down solid particles and creates stable emulsions or suspensions, common in the production of food products like mayonnaise and various pharmaceuticals.

Understanding the Critical Distinction: Application Drives Design

Choosing the wrong type of "mill" for a task will result in complete failure. The name is less important than the core function.

When to Use a Machining Mill

These are used for part production. The goal is to create a single, precisely dimensioned object from a solid block of metal, plastic, or wood. This is the domain of manufacturing and prototyping.

When to Use a Grinding Mill

These are used for bulk processing. The goal is to take a quantity of a coarse or brittle material and reduce its average particle size. This is common in mining, chemical processing, and material science.

When to Use a Dispersion Mill

These are used for formulation. The goal is to create a smooth, stable, and homogenous mixture from multiple components, often involving a liquid and a solid. This is essential in the food, cosmetic, pharmaceutical, and chemical industries.

Matching the Mill to Your Task

Choosing the correct machine begins with defining your objective.

- If your primary focus is creating a precise part from a solid block: You are looking for a machining mill, often called a CNC mill or manual milling machine.

- If your primary focus is turning a coarse material into a fine powder: A grinding mill, such as a ball mill, is the correct tool for the job.

- If your primary focus is blending a substance into a smooth, homogenous mixture: A dispersion mill, like a three roll mill or colloid mill, is what you need.

Understanding whether you intend to shape, grind, or mix is the definitive first step in navigating this technology.

Summary Table:

| Mill Type | Core Function | Key Principle | Common Examples |

|---|---|---|---|

| Machining Mill | Precise shaping of a solid workpiece | Subtractive manufacturing (material removal) | CNC Mill, Manual Milling Machine |

| Grinding Mill | Particle size reduction of bulk materials | Impact and attrition (crushing/abrasion) | Ball Mill |

| Dispersion/Mixing Mill | Homogenizing and mixing substances | High-shear force | Three Roll Mill, Colloid Mill |

Struggling to choose the right mill for your lab's material processing? The correct equipment is critical for achieving precise results, whether you are shaping prototypes, grinding samples into fine powders, or creating homogenous mixtures. KINTEK specializes in lab equipment and consumables, serving laboratory needs with the right milling solutions for your specific application. Our experts can help you select the perfect machine to enhance your efficiency and product quality. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- What is the diameter of the balls in a ball mill? Optimize Your Grinding Efficiency with the Right Size

- What is the role of a 3-dimensional mixer in glass raw material pretreatment? Enhance Chemical Consistency

- What is an example of pulverized? From Crushing Rocks to Winning Debates

- What size is a ball mill crushing? Understanding Its Role as a Grinding Tool, Not a Crusher

- What are the advantages of using an agate mortar for manual mixing? Protect Particle Integrity in Solid-State Batteries

- What is a grinder used in labs? Essential for Homogeneous Sample Preparation & Analysis

- What is the primary function of a ball mill in WCp/Cu FGM preparation? Achieve Uniform Powder Dispersion

- What is the function of a 3D motion mixer with WC balls for high-entropy alloys? Ensure Perfect Powder Homogeneity