At its core, vacuum heat treatment is a highly controlled process of heating a material within a sealed chamber from which the air has been removed. By eliminating the atmosphere, this method prevents unwanted surface reactions like oxidation and decarburization. The material is heated, held at a specific temperature, and then cooled in a controlled manner to achieve desired changes in its internal microstructure and physical properties.

The crucial insight is that vacuum heat treatment isn't just about heating metal; it's about fundamentally changing a material's properties in a pristine environment, ensuring the final product is clean, strong, and consistent without surface contamination.

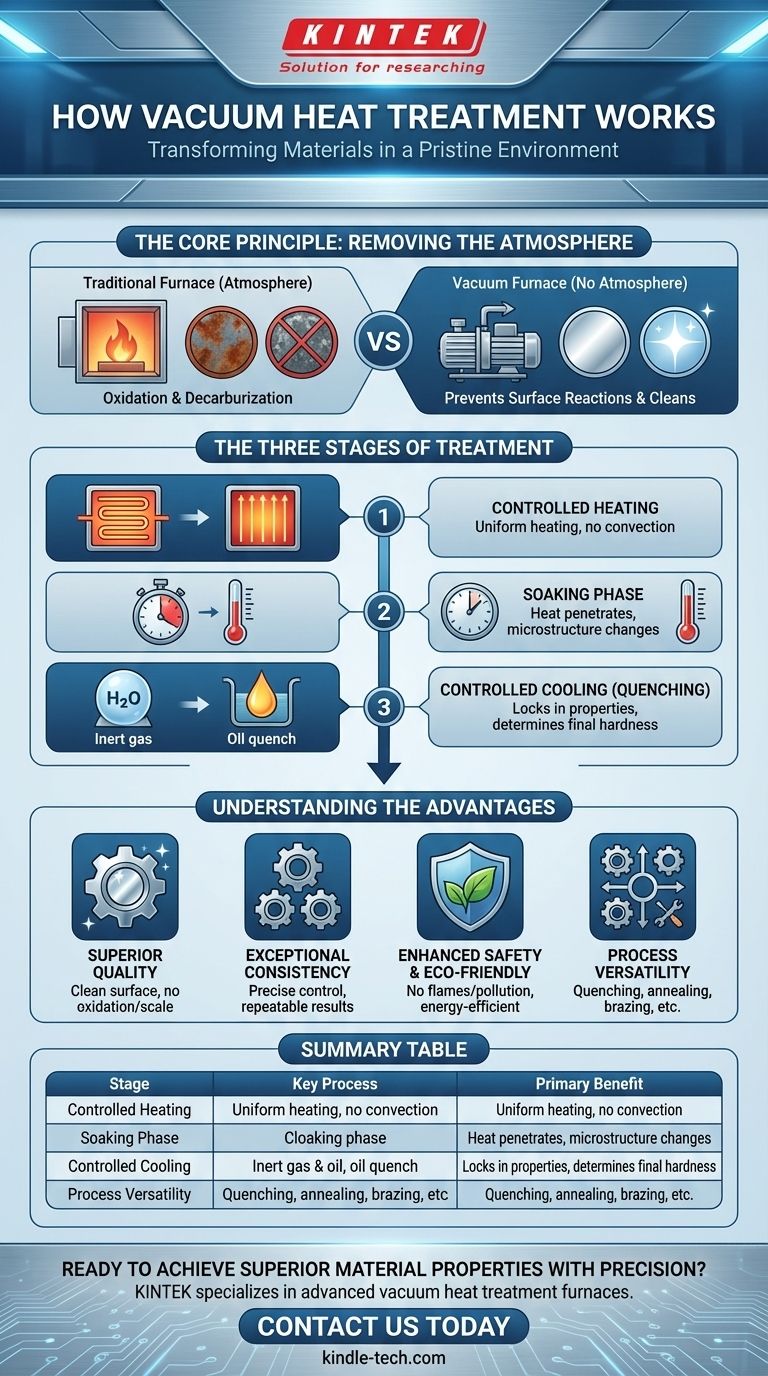

The Core Principle: Removing the Atmosphere

The defining characteristic of this process is the vacuum itself. Creating this environment is the first and most critical step, as it unlocks all the subsequent benefits.

Creating the Vacuum

The process begins by placing parts inside a sealed furnace chamber. A system of vacuum pumps then removes the air and other gases, drastically lowering the pressure inside.

This low-pressure environment is the opposite of a standard atmosphere; a "high vacuum" simply means a very low pressure with very few gas molecules remaining.

Preventing Surface Reactions

The primary reason for removing the atmosphere is to eliminate reactive gases, especially oxygen. In a traditional furnace, oxygen causes oxidation (scaling) and decarburization (loss of carbon from the surface), both of which weaken the material.

A vacuum environment starves these chemical reactions of the fuel they need to occur, preserving the material's surface integrity.

Cleaning and Degassing

The vacuum actively works to clean the parts. It helps vaporize and remove surface contaminants like oils or residues left over from manufacturing.

Furthermore, the low-pressure environment pulls dissolved gases, such as hydrogen and nitrogen, out from within the metal itself, a process known as degassing. This can prevent issues like hydrogen embrittlement, improving the material's toughness.

The Three Stages of Treatment

Once the vacuum is established, the heat treatment cycle proceeds through three distinct phases to precisely engineer the material's final characteristics.

1. Controlled Heating

Using internal resistance or induction elements, the furnace heats the workpiece to a specific, predetermined temperature. This heating is highly uniform because there is no air to cause convection currents or hot spots.

2. The Soaking Phase

The material is held at this target temperature for a set period. This "soaking" allows the heat to penetrate the entire part evenly, ensuring the desired changes to its internal crystal structure, or microstructure, are completed.

3. Controlled Cooling (Quenching)

After soaking, the part is cooled at a specific rate to lock in the new microstructure. This can be done by backfilling the chamber with a high-purity inert gas like nitrogen or argon, or by moving the part to an integrated oil quench tank.

The cooling speed is critical and determines the final hardness, strength, and other mechanical properties of the component.

Understanding the Advantages

Choosing a vacuum furnace is a decision driven by the need for superior quality, consistency, and safety.

Superior Part Quality

Parts emerge from a vacuum furnace with a clean, bright, and often shiny surface. Because no oxidation occurs, there is no scale to remove, which significantly reduces or eliminates the need for post-treatment cleaning processes like sandblasting or chemical baths.

Exceptional Consistency

Vacuum environments are hermetically sealed and computer-controlled. This allows for extremely precise management of temperature and pressure, leading to unparalleled invariability and repeatability from one batch to the next.

Enhanced Safety and Environmental Friendliness

This technology is inherently safer as it involves no open flames, combustible gases, or toxic byproducts. It is also more energy-efficient than many traditional methods and produces no pollution, making it an environmentally responsible choice.

Process Versatility

Nearly any heat treatment process can be performed in a vacuum. This includes quenching, annealing, tempering, brazing, and sintering, making it an incredibly versatile technology for modern manufacturing.

When to Choose Vacuum Heat Treatment

Your specific goal will determine if the precision and quality of vacuum heat treatment are the right fit for your application.

- If your primary focus is surface integrity and brightness: Vacuum treatment is the superior choice, as it prevents oxidation and delivers a clean part that requires minimal post-processing.

- If your primary focus is process repeatability for critical components: The tightly controlled nature of a vacuum furnace ensures that every part in every batch receives the exact same treatment.

- If your primary focus is joining complex assemblies: Vacuum brazing creates exceptionally strong, clean, and void-free joints without the use of flux, which can be corrosive.

- If your primary focus is environmental compliance and safety: Vacuum treatment eliminates the emissions, pollution, and operational hazards associated with many traditional atmospheric furnaces.

Ultimately, vacuum heat treatment offers an unparalleled level of control, transforming a simple heating process into a precision engineering tool.

Summary Table:

| Stage | Key Process | Primary Benefit |

|---|---|---|

| 1. Vacuum Creation | Removal of air and gases from the chamber | Prevents surface reactions (oxidation, decarburization) |

| 2. Controlled Heating | Uniform heating in a vacuum environment | Ensures consistent temperature throughout the part |

| 3. Soaking Phase | Holding at a specific temperature | Allows for complete microstructural changes |

| 4. Controlled Cooling | Quenching with inert gas or oil | Locks in desired hardness and mechanical properties |

Ready to achieve superior material properties with precision?

KINTEK specializes in advanced laboratory equipment, including vacuum heat treatment furnaces designed for critical applications. Our solutions deliver the clean, consistent, and repeatable results your lab demands, ensuring enhanced part quality, safety, and environmental compliance.

Contact us today to discuss how our vacuum heat treatment technology can meet your specific laboratory needs and elevate your manufacturing processes.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is thermal evaporation in a vacuum pressure? A Guide to High-Purity Thin Film Deposition

- What is the temperature of a vacuum brazing furnace? Key metrics for precision joining

- What role does a high-performance vacuum furnace play in the reduction of Magnéli phase titanium oxide?

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- Why is brazing more extensively used in industrial practice? Unlock High-Strength, Automated Joining

- What are the applications of sintering process? Fabricate Complex Parts with High-Performance Materials

- What is the importance of leakage in a vacuum system? Prevent Contamination and Process Failure

- What is conduction in vacuum? Understanding Heat Transfer in the Absence of Matter