At its core, an annealing furnace works by executing a precise three-stage thermal process. It heats a material to a specific temperature above its recrystallization point, holds it there for a set duration, and then cools it at a carefully controlled rate. This disciplined process fundamentally alters the material's internal microstructure, relieving internal stresses, reducing hardness, and increasing its ductility, making it easier to shape or machine.

An annealing furnace is not merely an oven; it is a precision instrument designed to manipulate a material’s atomic structure. Its effectiveness hinges on the absolute control of three variables: temperature, time, and atmosphere, which together determine the final mechanical properties of the workpiece.

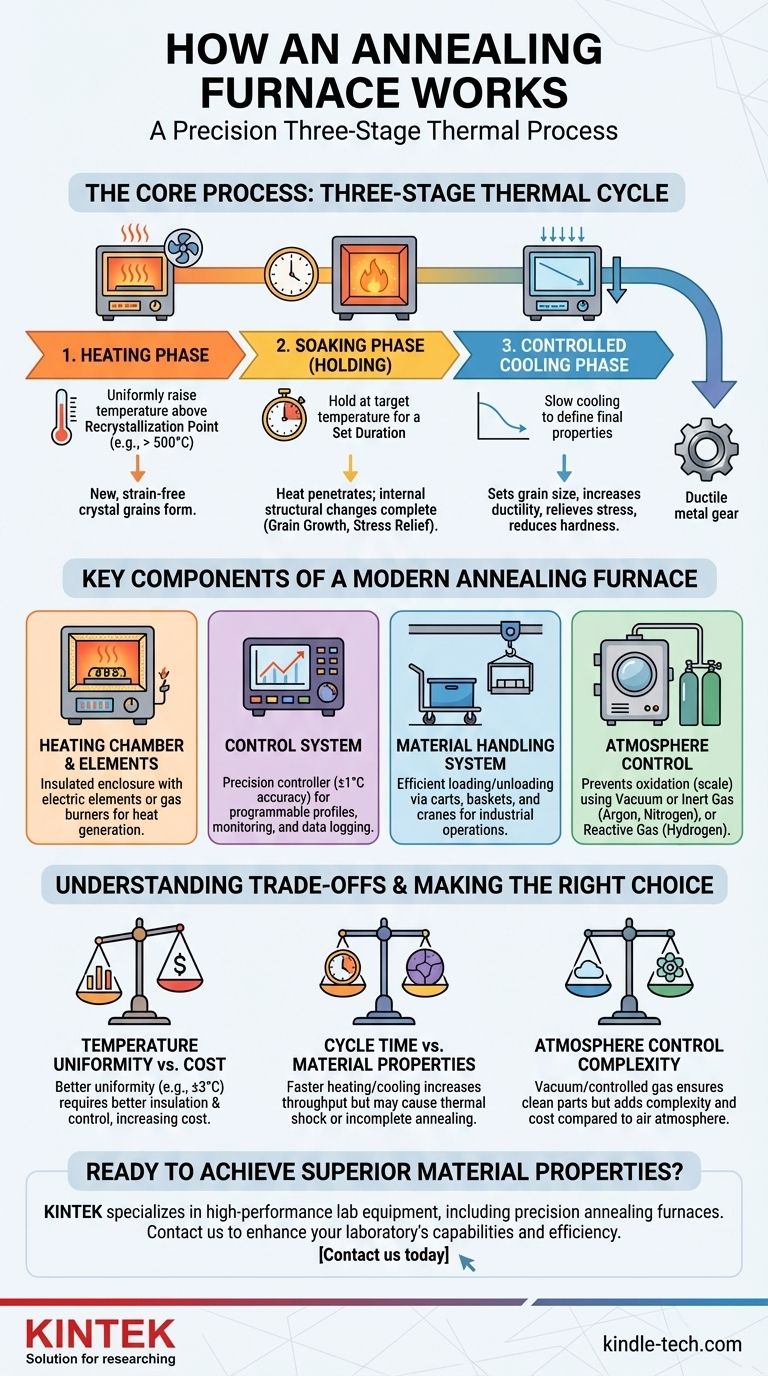

The Three Core Stages of Annealing

The entire annealing process can be broken down into three distinct and critical phases. Each stage serves a specific purpose in restructuring the material.

Stage 1: The Heating Phase

The initial goal is to raise the material's temperature uniformly and without inducing thermal shock. The furnace heats the material to a point above its recrystallization temperature, where new, strain-free crystal grains begin to form.

Heat is transferred to the material primarily through convection. Basic furnaces may use gravity convection, but high-performance systems use fans or blowers (mechanical convection) to circulate the heated atmosphere, ensuring a much more even and rapid temperature rise across the entire workpiece.

Stage 2: The Soaking Phase (Holding)

Once the target temperature is reached, the material is "soaked" by holding it at that temperature for a predetermined period.

This holding time is not arbitrary; it is calculated to ensure the heat penetrates the material's entire cross-section and that the internal structural changes, like grain growth and stress relief, have time to complete.

Stage 3: The Controlled Cooling Phase

The cooling stage is arguably the most critical for defining the final properties. The rate of cooling directly influences the final grain size and structure of the material.

For most annealing processes, a slow cooling rate is required. This is often achieved by simply turning off the furnace and allowing the material to cool gradually inside the insulated chamber. Other methods may involve forcing air to cool the furnace shell, which in turn slowly cools the internal atmosphere and the product.

Key Components of a Modern Annealing Furnace

A modern annealing furnace is a sophisticated system where several components work in concert to achieve a precise thermal cycle.

The Heating Chamber and Elements

This is the insulated enclosure where the work takes place. It is typically lined with refractory materials to withstand extreme temperatures and minimize heat loss. The heat itself is generated by electric resistance elements or, in some cases, gas burners.

The Control System

This is the brain of the furnace. A modern controller allows operators to program a precise temperature profile, setting the heating rates, soaking temperature, holding time, and cooling rates.

These systems provide real-time temperature monitoring, data logging for quality assurance, and critical safety alarms for over-temperature or system faults. High-precision controllers can maintain temperatures with an accuracy of ±1°C.

Material Handling System

For industrial-scale operations, an efficient system for loading and unloading is essential. This can include mobile carts or chassis that hold material baskets, with overhead cranes or hoists that lift the basket directly into the furnace chamber.

Atmosphere Control

Many materials, especially at high temperatures, will react with oxygen in the air, forming an undesirable surface layer of oxide (scale). To prevent this, advanced furnaces control the internal atmosphere.

A vacuum can be created to remove the air, or the chamber can be filled with a non-reactive inert gas like argon. In some cases, a reactive gas like hydrogen is used to actively clean the surface of the material during the process.

Understanding the Trade-offs

Choosing or operating an annealing furnace involves balancing performance with cost and complexity.

Temperature Uniformity vs. Cost

Achieving high temperature uniformity (e.g., ±3°C across the chamber) requires better insulation, more sophisticated controllers, and mechanical convection systems. While this increases the furnace's cost, it ensures consistent, high-quality results for every part. Less demanding applications may tolerate lower uniformity.

Cycle Time vs. Material Properties

While faster heating and cooling can increase production throughput, it can also create unwanted outcomes. Rapid heating can cause thermal shock in sensitive materials, and rapid cooling can prevent full stress relief or even introduce new hardness, defeating the purpose of annealing. The cycle must be engineered for the material, not just the production schedule.

Atmosphere Control Complexity

A simple air-atmosphere furnace is the least expensive to build and operate. However, the cost of post-process cleaning to remove oxide scale can be significant. A vacuum or controlled-gas furnace is more complex and expensive but delivers a clean, scale-free part directly, which is non-negotiable for many high-value components.

Making the Right Choice for Your Goal

The ideal annealing process is dictated entirely by the desired outcome for the material.

- If your primary focus is general stress relief for non-critical parts: A simple air-atmosphere furnace with basic temperature control and a slow cooling cycle will likely suffice.

- If your primary focus is achieving maximum ductility and a pristine surface finish: A furnace with high-precision temperature control, excellent uniformity, and a controlled atmosphere (vacuum or inert gas) is essential.

- If your primary focus is high-volume production of consistent parts: You need a system with automated material handling, programmable process controls, and carefully optimized cycle times that balance throughput with metallurgical requirements.

Understanding these core principles allows you to move beyond simply operating a furnace to truly engineering a material's final properties.

Summary Table:

| Stage | Purpose | Key Process |

|---|---|---|

| Heating | Raise material above recrystallization temperature | Uniform heating, often with mechanical convection |

| Soaking | Allow internal structural changes to complete | Hold at target temperature for a calculated duration |

| Cooling | Define final material properties | Controlled, slow cooling to set grain size and structure |

Ready to achieve superior material properties in your lab?

KINTEK specializes in high-performance lab equipment, including precision annealing furnaces. Our solutions deliver the exact temperature control, uniformity, and atmosphere management your projects demand.

Contact us today to discuss your specific application and discover how KINTEK can enhance your laboratory's capabilities and efficiency.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control