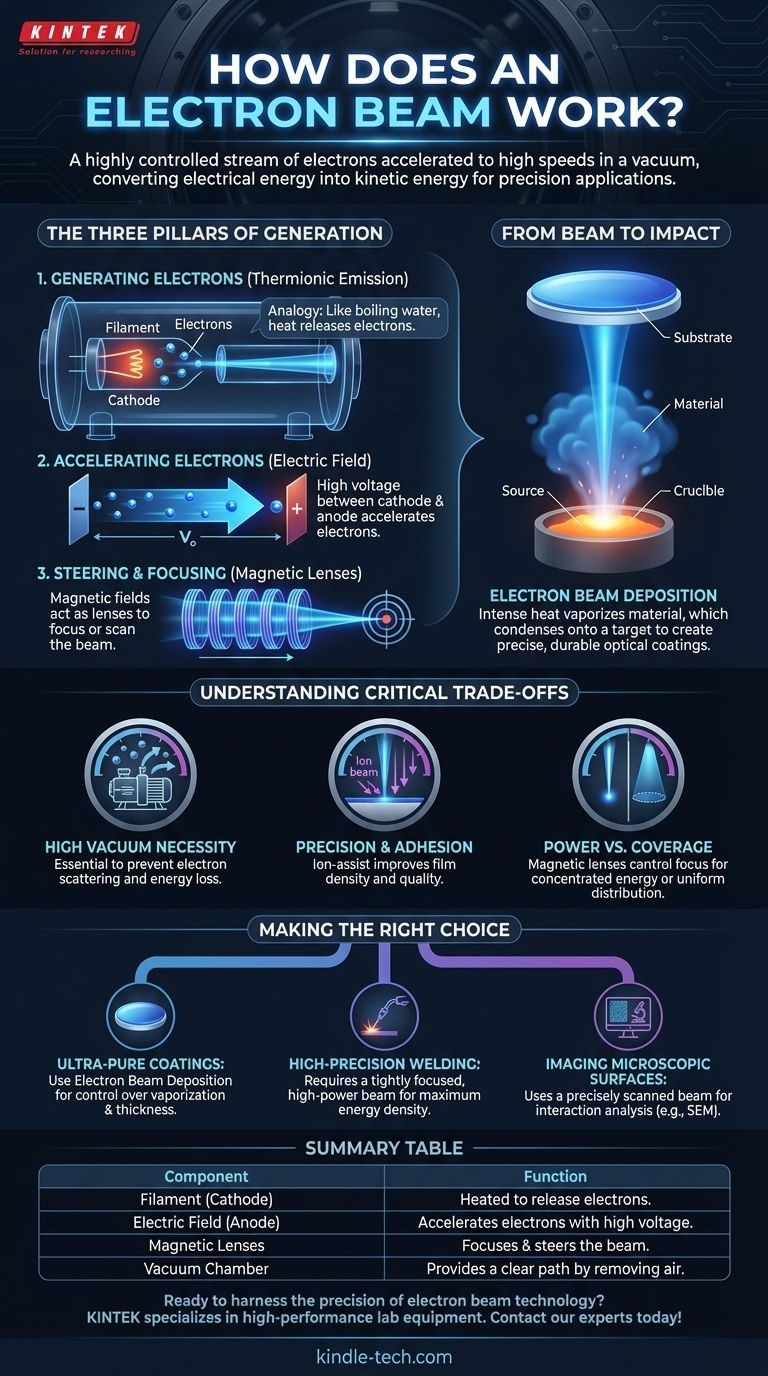

In essence, an electron beam is a highly controlled stream of electrons accelerated to high speeds in a vacuum. It is created by heating a filament to release electrons, using a strong electric field (a voltage difference) to accelerate them, and then using magnetic fields to precisely aim this stream of energy onto a target.

The core principle of an electron beam is converting electrical energy into the kinetic energy of electrons. This focused beam becomes a powerful tool for transferring that energy with incredible precision, either for heating, imaging, or material processing.

The Three Pillars of Electron Beam Generation

An electron beam system might seem complex, but its operation is based on three fundamental steps that occur within a high-vacuum chamber.

Step 1: Generating the Electrons

The process begins with a source, typically a metal filament. When this filament is heated to a very high temperature, it undergoes a process called thermionic emission.

This is analogous to boiling water; the heat provides enough energy for electrons to "escape" from the surface of the filament, forming a cloud of free electrons.

Step 2: Accelerating the Electrons

Once freed, the electrons are drawn away from the filament and accelerated by a powerful electric field. This is created by applying a high voltage between the filament (the cathode) and a positively charged plate (the anode).

Because electrons have a negative charge, they are intensely attracted to the positive anode, causing them to accelerate to extremely high speeds as they travel through the vacuum tube.

Step 3: Steering and Focusing the Beam

The high-velocity stream of electrons is then passed through a series of electromagnets. These magnetic fields act like lenses, focusing the beam to a fine point or steering it.

By precisely controlling these magnets, the beam can be scanned across a target area, creating what is sometimes called an electron "curtain," or held steady to concentrate energy on a single spot.

From Beam to Impact: Putting the Energy to Work

The true utility of an electron beam comes from what happens when these high-energy electrons strike a target material. Their kinetic energy is instantly converted into other forms, primarily intense, localized heat.

Application: Electron Beam Deposition

A primary industrial use is electron beam deposition, a method for creating highly durable and precise optical coatings.

In this process, the beam is directed at a crucible containing source material, such as a powder or granule. The intense heat generated by the beam's impact vaporizes this material.

Creating the Coating

This resulting vapor travels through the vacuum chamber and condenses onto the surface of the target object (like a lens or mirror).

Through precise computer control of the beam's power, vacuum levels, and substrate positioning, this process builds an exceptionally uniform and robust coating of a pre-specified thickness.

Understanding the Critical Trade-offs

While powerful, electron beam technology operates within specific constraints that are critical to its success.

The Necessity of a High Vacuum

The entire process must occur in a high vacuum. If air molecules were present, the electrons would collide with them, scattering the beam and causing it to lose its energy and focus. The vacuum ensures a clear path from the source to the target.

Precision and Adhesion

For applications like optical coatings, the quality is paramount. To improve the film's density and how well it sticks to the surface, an ion beam is sometimes used in conjunction with the electron beam. This "ion-assist" process results in more robust and stress-free coatings.

Power vs. Coverage

The system's magnetic lenses dictate the trade-off between power density and coverage area. A tightly focused beam concentrates all its energy on a tiny spot for cutting or welding, while a scanned beam can evenly distribute energy over a larger surface for coating or curing.

Making the Right Choice for Your Goal

The configuration of an electron beam system is determined entirely by its intended application.

- If your primary focus is creating ultra-pure, high-density coatings: Electron beam deposition is the ideal method, offering unparalleled control over material vaporization and film thickness.

- If your primary focus is high-precision welding or machining: A tightly focused, high-power beam is required to deliver maximum energy density to a single, small point.

- If your primary focus is imaging microscopic surfaces: A precisely scanned beam is used, where detectors measure how the beam interacts with a sample to generate an image (as in a Scanning Electron Microscope).

By mastering the generation and control of electrons in a vacuum, we can direct energy with a precision that enables cutting-edge manufacturing and analysis.

Summary Table:

| Component | Function |

|---|---|

| Filament (Cathode) | Heated to release electrons via thermionic emission. |

| Electric Field (Anode) | Accelerates electrons to high speeds using high voltage. |

| Magnetic Lenses | Focuses and steers the electron beam onto a target. |

| Vacuum Chamber | Provides a clear path for electrons by removing air molecules. |

Ready to harness the precision of electron beam technology in your lab? KINTEK specializes in high-performance lab equipment, including electron beam systems for deposition, welding, and analysis. Our solutions deliver the control and reliability you need for superior results. Contact our experts today to discuss how we can support your laboratory's specific needs!

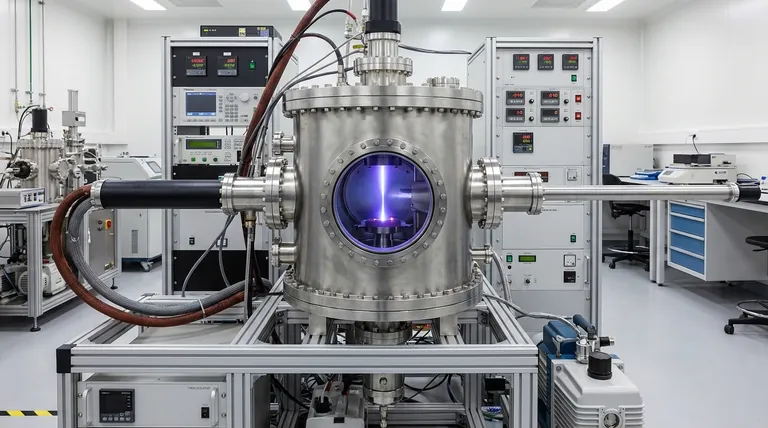

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the advantage of furnace brazing? Achieve Strong, Clean Joints with Minimal Distortion

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space