At its core, isostatic pressing works by using a fluid to apply uniform, all-around pressure to a powder sealed within a flexible mold. This method differs significantly from traditional pressing, which applies force from only one or two directions. By surrounding the mold with a pressurized medium, the powder is compacted evenly from every angle, resulting in a solid part with highly consistent properties.

The defining characteristic of isostatic pressing is its use of hydrostatic pressure—equal force exerted on all surfaces. This eliminates the density variations and internal stresses common in parts made with directional force, leading to superior final components.

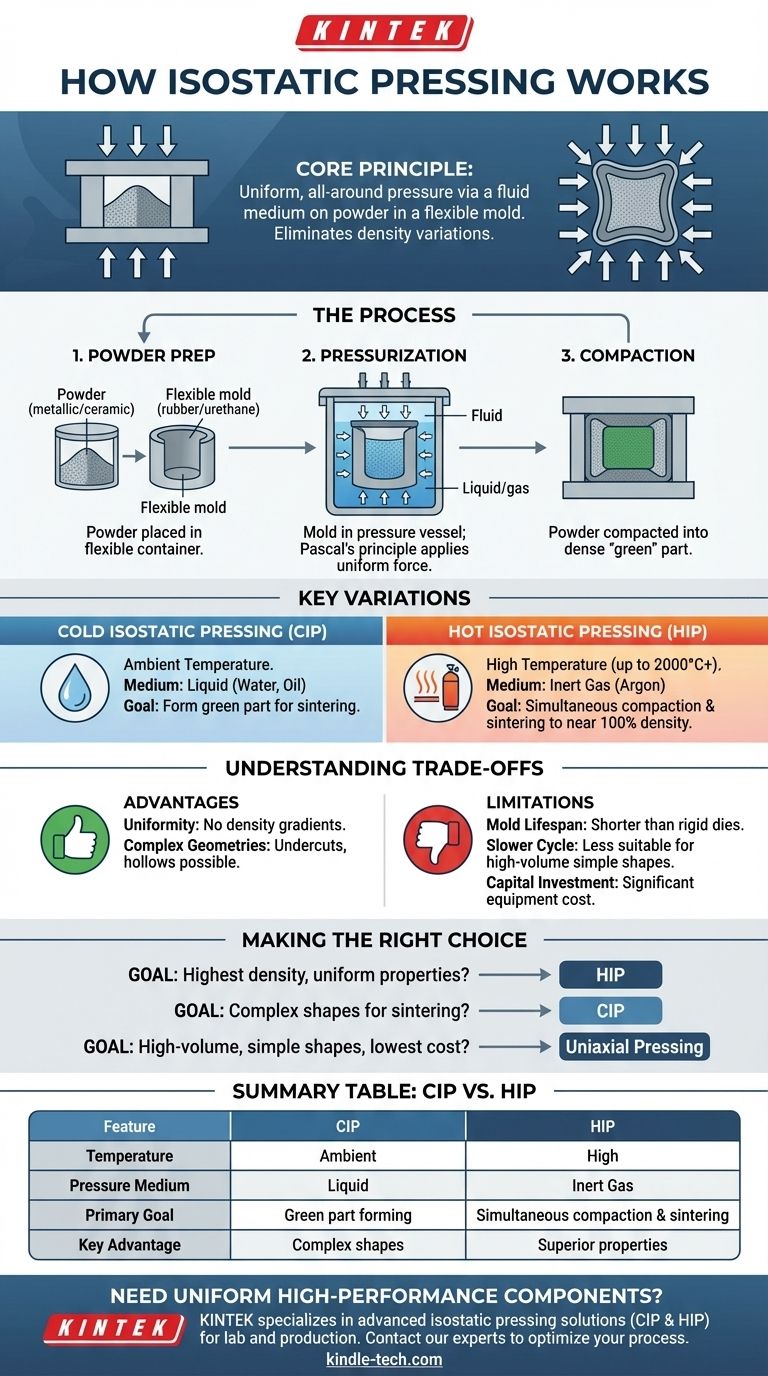

The Fundamental Principle: Pressure from All Directions

Traditional manufacturing often involves pushing a die into a powder, known as uniaxial pressing. Isostatic pressing abandons this directional approach for a more holistic one.

The Role of the Flexible Mold

The process begins by placing a powder, typically metallic or ceramic, into a flexible container or mold. This mold is often made of rubber, urethane, or PVC.

This container acts as a barrier, keeping the powder separate from the pressurizing fluid while accurately transmitting the pressure to the powder inside.

Applying Hydrostatic Pressure

The sealed mold is then placed inside a pressure vessel. This vessel is filled with a fluid, such as water or oil.

Pressure is applied to the fluid, which, according to Pascal's principle, transmits that pressure equally and uniformly to every point on the surface of the flexible mold.

The Compaction Process

As the mold is squeezed from all directions, it collapses inward, compacting the powder into a solid, dense mass called a "green" part. This part has the shape of the mold but is still fragile and requires further processing like sintering.

Key Variations of the Process

While the core principle remains the same, isostatic pressing is adapted for different materials and outcomes, primarily by controlling temperature.

Cold Isostatic Pressing (CIP)

This is the standard process performed at ambient temperature. It is used to create the initial green part with uniform density before it undergoes subsequent heating (sintering) to bond the particles together.

Hot Isostatic Pressing (HIP)

Hot isostatic pressing combines immense pressure with high temperatures inside the vessel. Instead of a liquid, an inert gas like argon is used as the pressure medium.

The simultaneous application of heat and pressure allows for both compaction and sintering to occur in a single step. This process can achieve nearly 100% theoretical density, eliminating internal voids and dramatically improving the material's mechanical properties.

Understanding the Trade-offs

Isostatic pressing offers significant advantages but is not the solution for every application. Understanding its limitations is key to using it effectively.

Advantages Over Uniaxial Pressing

The primary benefit is the uniformity of the final part. Because pressure is applied from all directions, there are no density gradients, which reduces the risk of warping or cracking during the final sintering stage.

This method also allows for the creation of more complex geometries, including parts with undercuts or hollow sections that are impossible to form with a rigid die.

Common Limitations and Considerations

The tooling, specifically the flexible molds, has a shorter lifespan than the hardened steel dies used in conventional pressing.

The process cycle time for isostatic pressing can be slower than for high-speed mechanical presses, making it less suitable for extremely high-volume production of simple shapes.

Finally, the equipment required, especially for hot isostatic pressing, represents a significant capital investment.

Making the Right Choice for Your Goal

Selecting the right compaction method depends entirely on the desired characteristics of the final component.

- If your primary focus is creating parts with the highest possible density and uniform mechanical properties: Hot Isostatic Pressing (HIP) is the superior choice for eliminating all internal porosity.

- If your primary focus is producing complex shapes that cannot be made with rigid dies: Cold Isostatic Pressing (CIP) provides the geometric freedom needed before final sintering.

- If your primary focus is high-volume manufacturing of simple shapes at the lowest cost: Traditional uniaxial die compaction is likely the more economical and faster method.

Ultimately, understanding how isostatic pressing leverages uniform pressure allows you to produce components with a level of quality and complexity that other methods cannot achieve.

Summary Table:

| Feature | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Ambient (Room Temperature) | High Temperature (up to 2000°C+) |

| Pressure Medium | Liquid (Water, Oil) | Inert Gas (Argon) |

| Primary Goal | Forming a 'green' part with uniform density for sintering | Simultaneous compaction and sintering to near 100% density |

| Key Advantage | Ability to form complex shapes | Superior mechanical properties, elimination of porosity |

Need to produce high-performance components with uniform density?

KINTEK specializes in advanced isostatic pressing solutions for your laboratory or production needs. Whether you are working with advanced ceramics, metals, or composites, our expertise in Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) can help you achieve superior material properties and complex geometries that are impossible with traditional methods.

Contact our experts today via our Contact Form to discuss how our lab equipment and consumables can optimize your material development and manufacturing processes.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- What types of materials are used for canisters in the HIP process? Optimized Choices for Material Densification

- What are the examples of cold working metals? Key Processes for Stronger, Precision Parts

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- Is isostatic pressing expensive? Achieve Superior Material Uniformity & Complex Shapes

- Why is a cold isostatic press advantageous for Argyrodite sulfide solid-state batteries? Achieve Optimal Densification

- What is the isostatic pressing method for producing ceramic products? Achieve Uniform, High-Density Ceramic Components

- What is HIP and CIP in powder metallurgy? Choose the Right Process for Your Materials