At its core, induction melting uses powerful, changing magnetic fields to turn metal into its own heat source. Instead of applying external flames or heating elements, this process induces strong electrical currents directly within the metal, causing it to heat rapidly and uniformly from the inside out.

The central principle of induction melting is electromagnetic induction. An alternating current in an outer coil generates a magnetic field that induces internal electrical currents, called eddy currents, within the metal. The metal’s own electrical resistance converts these currents into intense heat, leading to a clean, controlled, and rapid melt.

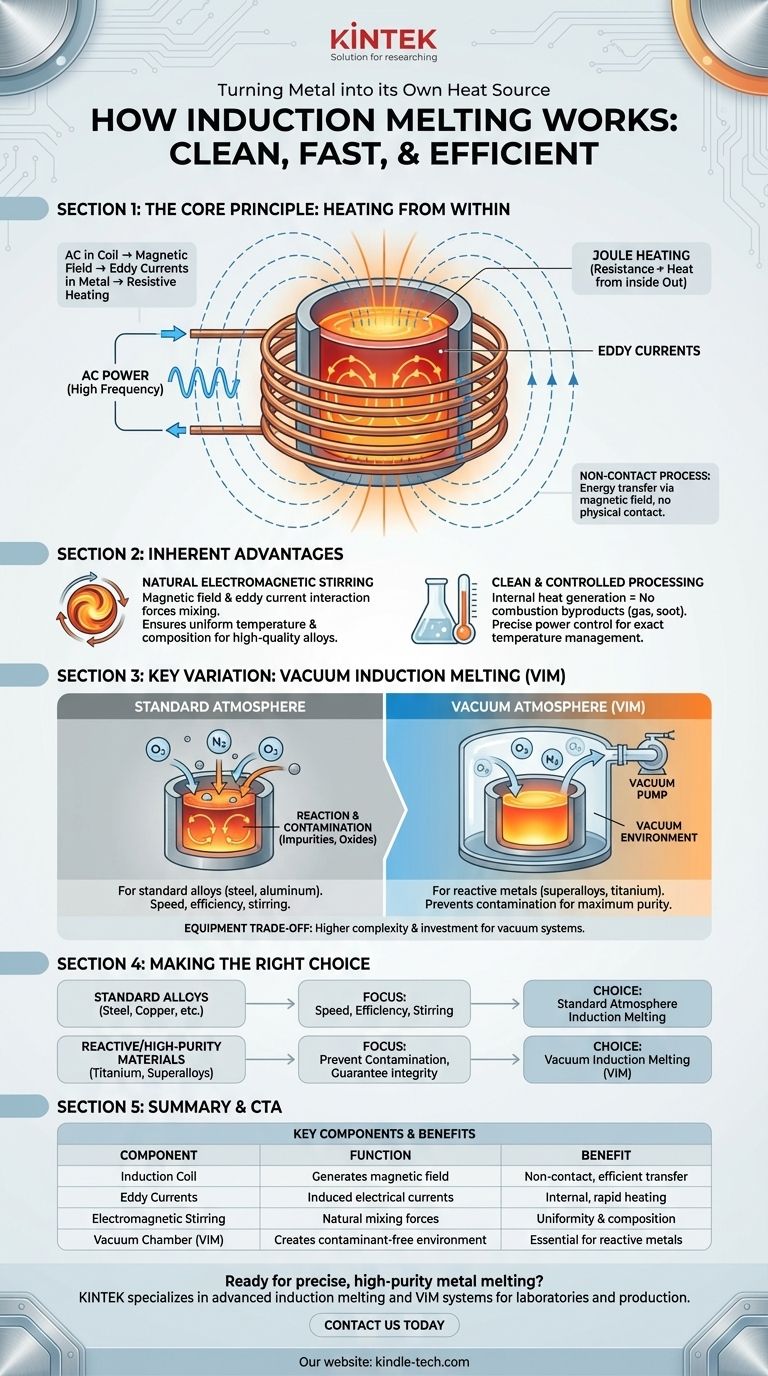

The Core Principle: Heating from Within

Induction melting is a non-contact process. The elegance of the system lies in its ability to transfer energy through a magnetic field without the heating source ever touching the material.

The Induction Coil and Power Supply

The process begins with a high-frequency alternating current (AC) sent through a copper induction coil. This coil, often water-cooled to handle the immense energy, is shaped to surround the crucible containing the metal charge.

The Magnetic Field and Eddy Currents

According to Faraday's Law of Induction, the alternating current in the coil produces a powerful and rapidly changing magnetic field around it. When the conductive metal is placed within this field, the field induces circulating electrical currents within the metal itself. These are known as eddy currents.

Think of it like a transformer. The induction coil is the primary winding, and the piece of metal being melted acts as a single-turn secondary winding that is short-circuited on itself.

Resistive Heating (Joule Heating)

All metals have some natural electrical resistance. As the powerful eddy currents are forced to flow through the metal, they encounter this resistance. This opposition converts the electrical energy directly into thermal energy, a phenomenon known as Joule heating. This heat is generated inside the metal, ensuring an extremely fast and efficient melting process.

Beyond Melting: Inherent Advantages

The physics that drives induction melting also provides unique benefits that are critical for modern metallurgy, especially when creating high-performance alloys.

Natural Electromagnetic Stirring

The interaction between the magnetic field and the eddy currents creates forces within the molten metal bath. These forces produce a natural stirring or mixing action. This electromagnetic stirring is crucial for ensuring the melt has a uniform temperature and chemical composition, which is vital for producing high-quality, homogenous alloys.

Clean and Controlled Processing

Since heat is generated internally, there is no contamination from combustion byproducts like gas or soot, which are common in traditional fuel-fired furnaces. This results in a much purer final product. The power supplied to the coil can be precisely controlled, allowing for exact temperature management throughout the melting cycle.

Understanding the Key Variation: Vacuum Induction Melting

While the principle remains the same, the environment in which melting occurs is a critical variable. This leads to a major distinction in furnace design and application.

The Need for a Vacuum: When Air is the Enemy

Many advanced metals and superalloys, such as those based on titanium or nickel, are highly reactive. When melted in the open air, they will readily react with oxygen and nitrogen. This forms undesirable impurities and oxides that compromise the material's final mechanical properties.

Vacuum Induction Melting (VIM) solves this problem by placing the entire furnace—coil, crucible, and charge—inside a sealed, airtight chamber. Air is pumped out to create a vacuum before melting begins. This protects the reactive molten metal from atmospheric contamination, ensuring maximum purity and performance.

Equipment Complexity and Trade-offs

The primary trade-off of induction melting, especially VIM, is equipment complexity. The systems require sophisticated high-frequency power supplies, robust water-cooling circuits to protect the induction coil, and, in the case of VIM, extensive vacuum pumps and monitoring gauges. This represents a significant capital investment and requires specialized maintenance.

Making the Right Choice for Your Goal

Understanding induction melting allows you to select the right process for your specific material and quality requirements.

- If your primary focus is rapidly melting standard alloys (e.g., steel, iron, copper, aluminum): Standard atmosphere induction melting provides unmatched speed, energy efficiency, and the homogenizing benefit of electromagnetic stirring.

- If your primary focus is producing high-purity, reactive materials (e.g., superalloys, titanium, specialty steels): Vacuum Induction Melting (VIM) is the essential choice to prevent atmospheric contamination and guarantee the integrity of the final material.

Ultimately, induction melting provides a level of precision and purity that is often unattainable with other methods.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Induction Coil | Generates alternating magnetic field | Non-contact, efficient energy transfer |

| Eddy Currents | Induced electrical currents within the metal | Internal, rapid heating (Joule effect) |

| Electromagnetic Stirring | Natural mixing from magnetic forces | Uniform temperature and composition |

| Vacuum Chamber (VIM) | Creates a contaminant-free environment | Essential for reactive metals like titanium and superalloys |

Ready to achieve precise, high-purity metal melting? KINTEK specializes in advanced induction melting solutions, including Vacuum Induction Melting (VIM) systems, designed for laboratories and production facilities working with high-performance alloys. Our equipment ensures rapid, contamination-free processing with exact temperature control. Let our experts help you select the ideal system for your material goals. Contact us today to discuss your application!

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion