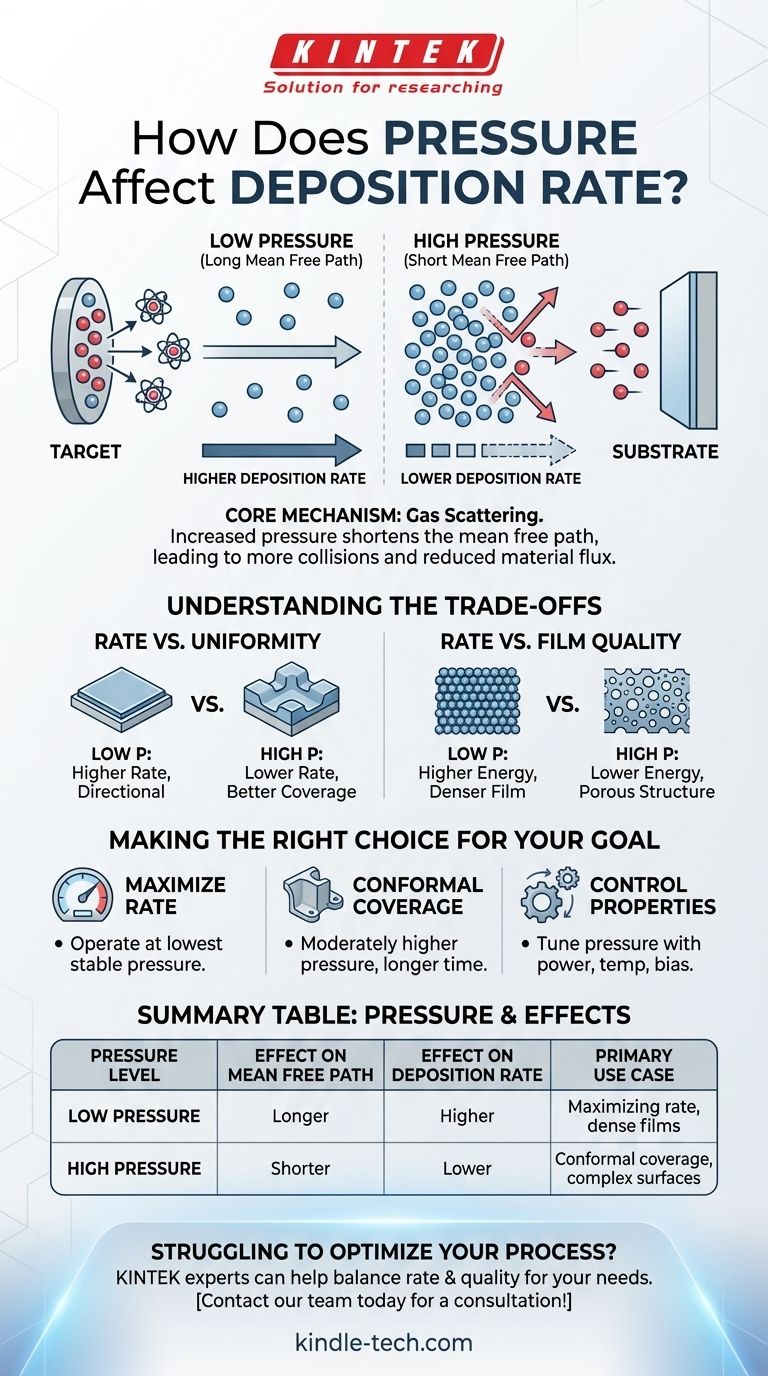

In deposition processes, chamber pressure is a critical parameter that inversely affects the deposition rate. While factors like magnetron power and target-to-substrate distance are primary drivers of how much material is sputtered, pressure governs how efficiently that material travels to your substrate. Generally, as you increase the process pressure, the deposition rate will decrease.

The core reason for this relationship is gas scattering. Higher pressure shortens the mean free path of sputtered atoms, causing more collisions with gas molecules, which reduces the number of atoms that successfully reach and deposit on the substrate.

The Core Mechanism: Gas Scattering

To understand why pressure has this effect, we need to look at what's happening at the atomic level inside the deposition chamber.

Mean Free Path

The mean free path is the average distance a particle—in this case, a sputtered atom from the target—can travel before it collides with another particle, such as an atom of the process gas (e.g., Argon).

How Pressure Affects Collisions

Increasing the chamber pressure means you are increasing the density of gas atoms. With more gas atoms packed into the same space, the mean free path for the sputtered atoms becomes significantly shorter. This directly results in a higher probability of collisions.

The Impact on Material Transport

When a sputtered atom collides with a gas atom, it loses kinetic energy and changes its trajectory. After multiple collisions, the atom may be deflected so much that it never reaches the substrate, instead depositing on the chamber walls.

Why Deposition Rate Decreases with Higher Pressure

The increased scattering at higher pressures has a direct and measurable impact on the rate of film growth.

Reduced Material Flux

The fundamental reason the rate drops is a reduction in material flux—the number of sputtered atoms arriving at the substrate surface per unit of time. More collisions mean fewer atoms complete the journey from target to substrate.

The Role of Other Parameters

It's important to recognize that pressure does not act in isolation. The reference correctly notes that power and target-to-substrate distance are hugely influential. Increasing power sputters more material off the target, while decreasing the distance gives sputtered atoms a shorter, more direct path. However, pressure modulates the efficiency of that transport regardless of these other settings.

Understanding the Trade-offs

Adjusting pressure is not just about changing the deposition rate; it's a critical lever for tuning the final properties of your thin film. Lowering pressure to maximize rate is not always the best strategy.

Rate vs. Uniformity

While a lower pressure (and longer mean free path) is great for rate, it can create a very directional deposition, potentially leading to poor thickness uniformity on substrates with complex 3D topography. A higher pressure increases scattering, which can help coat sidewalls more effectively, improving conformal coverage at the cost of a lower rate.

Rate vs. Film Quality

The energy of the depositing atoms is also critical. At lower pressures, atoms arrive at the substrate with higher kinetic energy, which typically results in a denser, higher-quality film. At higher pressures, repeated collisions thermalize the sputtered atoms, causing them to land with less energy, which can lead to more porous film microstructures.

Making the Right Choice for Your Goal

You must balance the deposition rate with the desired film characteristics for your specific application.

- If your primary focus is maximizing deposition rate: Operate at the lowest pressure that can reliably sustain a stable plasma process.

- If your primary focus is achieving conformal coverage on a complex surface: A moderately higher pressure may be required to increase scattering, but be prepared for a significantly longer deposition time.

- If your primary focus is controlling film properties like density and stress: Pressure is a key tuning parameter that must be optimized alongside power, temperature, and substrate bias to achieve the desired result.

Ultimately, controlling pressure is about mastering the balance between deposition speed and the final quality of your thin film.

Summary Table:

| Pressure Level | Effect on Mean Free Path | Effect on Deposition Rate | Primary Use Case |

|---|---|---|---|

| Low Pressure | Longer | Higher | Maximizing rate, dense films |

| High Pressure | Shorter | Lower | Conformal coverage, complex surfaces |

Struggling to Optimize Your Deposition Process? KINTEK specializes in providing high-performance lab equipment and consumables for precise thin film deposition. Our experts can help you select the right sputtering system and parameters to achieve the perfect balance of deposition rate and film quality for your specific research or production needs. Contact our team today for a consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition