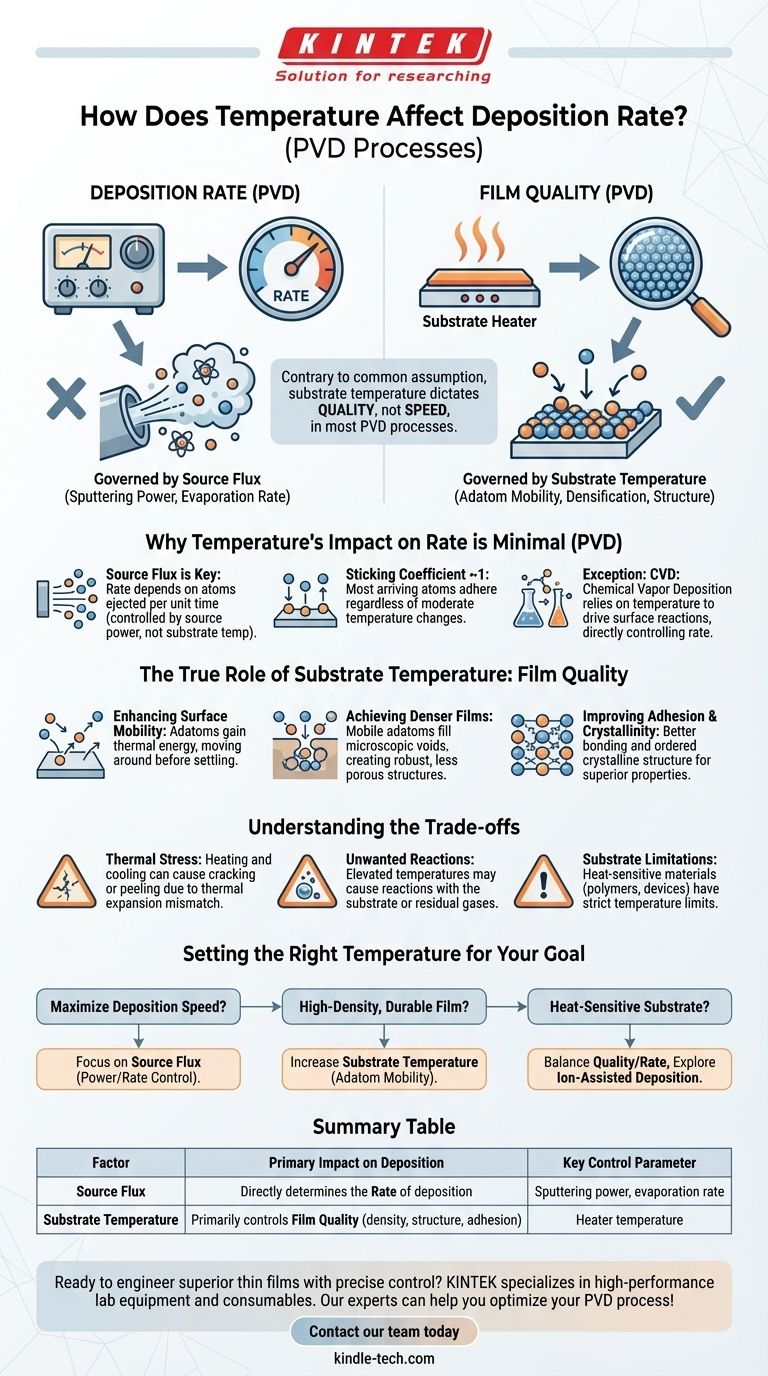

Contrary to a common assumption, substrate temperature has very little direct impact on the deposition rate in most physical vapor deposition (PVD) processes. The rate is primarily governed by the amount of material leaving the source. Temperature's critical role is not in controlling speed, but in dictating the quality, density, and structure of the final film.

The central takeaway is this: Stop thinking of temperature as a control for deposition rate and start seeing it as the primary control for film quality. Your process temperature directly engineers the final properties of the material you are depositing.

Why Temperature's Impact on Rate is Minimal

The Process is Governed by Source Flux

In common deposition techniques like sputtering or thermal evaporation, the process is fundamentally about moving atoms from a source material to a substrate. The rate is almost entirely dependent on how many atoms are ejected from the source per unit of time.

This "source flux" is controlled by parameters like sputtering power or filament temperature, not the temperature of the substrate receiving the atoms.

Surface Sticking Coefficient

For most materials, the "sticking coefficient"—the probability that an arriving atom will adhere to the surface—is already very close to 1. Raising the substrate temperature doesn't significantly change this. The atoms that arrive will almost always stick, regardless of a moderate temperature change.

The Exception: Chemical Vapor Deposition (CVD)

It is critical to distinguish PVD from Chemical Vapor Deposition (CVD). In CVD, precursor gases must thermally decompose and react on the substrate surface to form the film. In this case, substrate temperature is a primary driver of the reaction rate and therefore directly controls the deposition rate.

The True Role of Substrate Temperature: Film Quality

Enhancing Surface Mobility

The most important function of substrate heating is to give depositing atoms (known as "adatoms") more thermal energy once they land on the surface. This energy allows them to move around before locking into place.

Achieving Denser Films

This increased surface mobility is the key to a high-quality film. Mobile adatoms can find more energetically favorable sites, filling in microscopic voids and gaps. This process, known as densification, results in a more robust and less porous film structure.

Improving Adhesion and Crystallinity

Adatom mobility also allows for better bonding with the substrate material, improving adhesion. Furthermore, with enough energy, atoms can arrange themselves into an ordered, crystalline structure rather than a disordered, amorphous one, which can be critical for optical or electronic properties.

Understanding the Trade-offs

Thermal Stress and Mismatch

Heating a substrate and then cooling it after deposition can introduce significant stress. If the film and the substrate have different coefficients of thermal expansion, this stress can cause the film to crack, peel, or delaminate.

Potential for Unwanted Reactions

At elevated temperatures, the depositing material may react with the substrate or with residual gases in the vacuum chamber. This can create undesirable interface layers or contaminate the film, altering its intended properties.

Substrate Limitations

Many substrates, such as polymers, plastics, or complex pre-fabricated devices, have strict temperature limits. Exceeding these limits can damage or destroy the substrate, making high-temperature deposition impossible.

Setting the Right Temperature for Your Goal

To properly control your process, you must decouple the concepts of rate and quality. Use your source controls for rate and your substrate heater for quality.

- If your primary focus is maximizing deposition speed: Concentrate on increasing the source flux (e.g., sputtering power or evaporation rate), as this is the direct control for deposition rate.

- If your primary focus is a high-density, durable film: A higher substrate temperature is your most effective tool for increasing adatom mobility, which reduces voids and improves the film structure.

- If you are working with a heat-sensitive substrate: You must find a balance, potentially accepting a lower-density film or exploring alternative energy sources like ion-assisted deposition to improve quality without high heat.

Ultimately, treat substrate temperature not as a throttle for speed, but as a precision dial for controlling the final quality and performance of your film.

Summary Table:

| Factor | Primary Impact on Deposition | Key Control Parameter |

|---|---|---|

| Source Flux | Directly determines the Rate of deposition | Sputtering power, evaporation rate |

| Substrate Temperature | Primarily controls Film Quality (density, structure, adhesion) | Heater temperature |

Ready to engineer superior thin films with precise control?

KINTEK specializes in high-performance lab equipment and consumables for all your deposition needs. Our experts can help you select the right system to achieve the perfect balance of rate and quality for your specific application.

Contact our team today to optimize your PVD process!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings