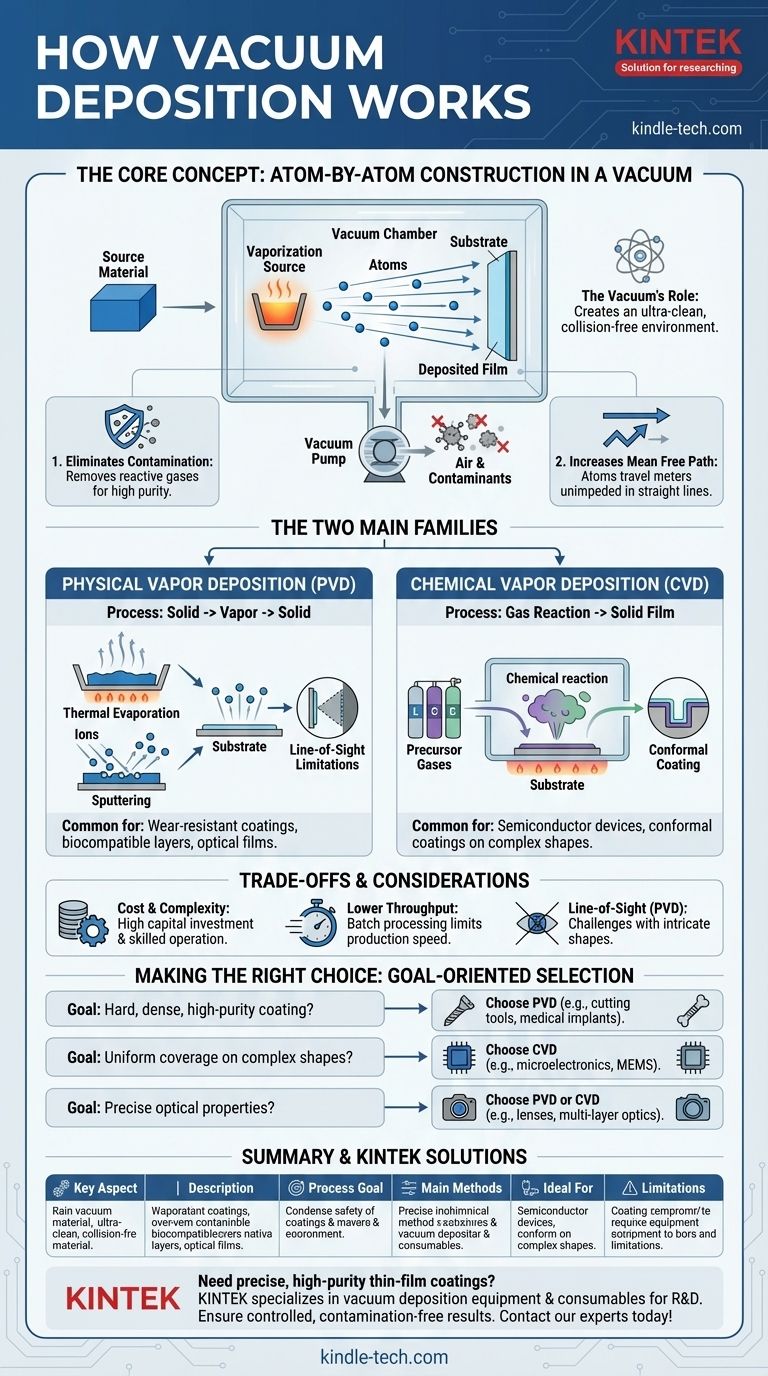

At its core, vacuum deposition is a family of processes for applying extremely thin, high-purity layers of material onto a surface. This is accomplished inside a chamber where the air and other gases have been pumped out to create a vacuum. In this environment, a source material is turned into a vapor, allowing its individual atoms or molecules to travel unimpeded and bond to a target object, known as a substrate.

The critical insight is that the vacuum itself is the most important tool in the process. Its purpose is to create an ultra-clean, collision-free environment that enables the precise, atom-by-atom construction of a film with carefully controlled properties.

The Role of the Vacuum: Creating a Perfect Pathway

The effectiveness of vacuum deposition hinges on what the vacuum environment makes possible. It is not merely the absence of air, but the creation of a highly controlled space for atomic-level construction.

Eliminating Contamination

The normal atmosphere is filled with reactive gases like oxygen, nitrogen, and water vapor. If present during deposition, these molecules would collide with and chemically bond to the coating material, creating impurities and altering the film's properties.

A vacuum removes these potential contaminants, ensuring the deposited film is as chemically pure as possible.

Increasing the "Mean Free Path"

Mean free path refers to the average distance a particle can travel before colliding with another particle. In air at sea level, this distance is incredibly short—only about 68 nanometers.

By creating a vacuum, the mean free path is extended to meters. This ensures that the vaporized material travels in a straight line directly from the source to the substrate without being scattered or blocked by air molecules.

Enabling Precise Control

With atmospheric gases removed, engineers can introduce specific, high-purity gases in precise amounts to assist the process.

This could be an inert gas like argon to bombard a source material (sputtering) or a reactive gas like nitrogen to intentionally form a new compound (like titanium nitride) on the substrate surface. This gives operators complete control over the film's final composition.

The Two Main Families of Vacuum Deposition

While "vacuum deposition" is a broad term, the methods generally fall into two major categories based on how the material is generated and deposited.

Physical Vapor Deposition (PVD)

In PVD, the coating material starts as a solid and is turned into a vapor through a purely physical process. This vapor then travels through the vacuum and condenses on the substrate.

The material of the final film is the same as the source material. Common PVD methods include thermal evaporation (heating a material until it vaporizes) and sputtering (bombarding a material with energetic ions).

Chemical Vapor Deposition (CVD)

In CVD, the process uses chemical reactions to create the film. One or more precursor gases are introduced into the vacuum chamber.

These gases react on or near the hot substrate surface, and one of the byproducts of that chemical reaction is the solid material that forms the film. This method is excellent for creating highly uniform, or "conformal," coatings over complex shapes.

Understanding the Trade-offs

While powerful, vacuum deposition is not a universal solution. It comes with a distinct set of operational and physical limitations that must be considered.

Cost and Complexity

Vacuum systems, including chambers, high-power pumps, and process controllers, represent a significant capital investment. They also require trained technicians to operate and maintain, adding to the overall cost.

Lower Throughput

Most vacuum deposition processes are performed in batches, where a set of parts must be loaded, the chamber sealed and pumped down, the process run, and the chamber vented. This cycle limits production speed compared to continuous processes like electroplating or painting.

Line-of-Sight Limitations

In many PVD processes, the coating can only form on surfaces with a direct, uninterrupted line of sight to the vaporization source. This makes it challenging to uniformly coat intricate shapes with hidden surfaces or deep cavities.

Making the Right Choice for Your Goal

The decision to use vacuum deposition, and which method to choose, depends entirely on the required properties of the final film and the geometry of the part being coated.

- If your primary focus is a hard, dense, and highly pure coating: PVD is often the superior choice for applications like wear-resistant coatings on cutting tools or biocompatible layers on medical implants.

- If your primary focus is perfectly uniform coverage on complex shapes: CVD excels at creating conformal coatings, making it a cornerstone of the semiconductor industry for coating intricate microelectronic components.

- If your primary focus is precise optical properties: Both PVD and CVD are used to create multi-layer coatings on lenses and optics, where precise control over thickness and refractive index is critical for performance.

Ultimately, understanding these core principles empowers you to select the deposition strategy that best aligns with your material and performance requirements.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Apply thin, high-purity material layers onto a substrate (e.g., silicon wafer, tool, lens). |

| Core Mechanism | Vaporize a source material in a vacuum chamber; atoms travel unimpeded to coat the target. |

| Main Methods | PVD (Physical Vapor Deposition): Vaporize solid source (e.g., sputtering, evaporation). CVD (Chemical Vapor Deposition): Use gas reactions to deposit solid films. |

| Ideal For | Semiconductors, optical coatings, medical devices, and wear-resistant tool coatings. |

| Limitations | High equipment cost, batch processing (lower throughput), line-of-sight coating challenges (PVD). |

Need precise, high-purity thin-film coatings for your lab or production? KINTEK specializes in vacuum deposition equipment and consumables for laboratories and R&D teams. Whether you're developing semiconductors, optical components, or medical devices, our solutions ensure controlled, contamination-free results. Contact our experts today to discuss your coating requirements and explore how KINTEK can enhance your material performance!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application