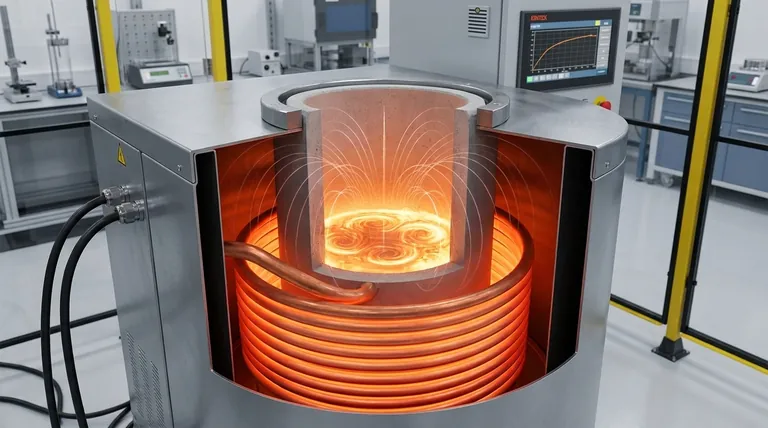

In an induction furnace, heat is generated directly within the metal itself through a process called electromagnetic induction. A powerful, alternating current flows through a copper coil, creating a rapidly reversing magnetic field. This field induces strong electrical currents—known as eddy currents—inside the metal charge, and the material's natural resistance to these currents generates intense heat, causing it to melt.

Unlike a conventional oven that heats from the outside-in, an induction furnace uses electromagnetism to turn the metal into its own heat source. This fundamental difference is the key to its speed, efficiency, and ability to produce high-purity melts.

The Core Principle: Electromagnetic Induction at Work

To understand how an induction furnace operates, it’s best to break the process down into its key physical principles. The entire system is a practical application of Faraday's Law of Induction.

The Copper Coil and the Magnetic Field

An induction furnace is built around a non-conductive crucible, which holds the metal to be melted. This crucible is encircled by a coil of heavy copper tubing.

When a high-frequency alternating current (AC) is passed through this coil, it generates a powerful and rapidly changing magnetic field both inside and outside the coil.

Inducing Eddy Currents

This dynamic magnetic field penetrates the conductive metal placed inside the crucible. As the magnetic field lines rapidly change polarity, they induce circular electrical currents within the metal.

These induced currents are called eddy currents. They are similar to the whirlpools that form in water, but they consist of flowing electrons instead of water molecules.

Joule Heating: Resistance Creates Heat

All conductive materials have some level of electrical resistance. As the strong eddy currents flow through the metal, they encounter this resistance.

This opposition generates immense heat through a principle known as Joule heating. It is the primary mechanism that brings the metal to its melting point and beyond.

An Important Secondary Effect: Magnetic Hysteresis

For certain types of metal, a second heating phenomenon occurs alongside Joule heating, adding to the furnace's efficiency.

What is Magnetic Hysteresis?

This effect only applies to ferromagnetic materials, such as iron. These materials are composed of tiny magnetic "domains."

When exposed to the furnace's magnetic field, these domains rapidly align themselves with the field. Because the field is alternating thousands of times per second, the domains are forced to constantly and rapidly flip their orientation.

How Hysteresis Generates Heat

This rapid realignment creates a kind of internal friction within the material's atomic structure. This friction generates a significant amount of supplemental heat.

This effect stops once the metal reaches a specific temperature (its Curie point), at which it loses its magnetic properties. From that point on, only Joule heating continues the melting process.

Understanding the Trade-offs: Induction vs. Other Furnaces

The unique "inside-out" heating method of an induction furnace gives it distinct advantages and makes it suited for different tasks compared to other furnace types.

Purity: No Contamination from Fuel

Unlike a gas-fired furnace that burns fuel, an induction furnace has no combustion. The heat originates from the charge itself.

This means no impurities from fuel or combustion byproducts can contaminate the metal, making induction ideal for producing high-purity alloys for aerospace, medical, or electronics applications.

Control: Direct and Rapid Heating

In a resistance furnace, heating elements get hot and slowly transfer that heat to the material. Induction is a direct process where energy is instantly transferred to the metal.

This allows for extremely fast startup times and very precise temperature control, as turning off the power immediately stops heat generation.

Application: A Tool for Precision

While an electric arc furnace is a workhorse for melting massive quantities of steel scrap, it does so with a violent electric arc that can be difficult to control precisely.

An induction furnace excels in applications requiring clean, controlled, and repeatable melting of specific alloys, from a few pounds to many tons.

Making the Right Choice for Your Goal

The decision to use an induction furnace over another heating technology depends entirely on the requirements of your final product.

- If your primary focus is material purity and precise control: An induction furnace is superior because it generates heat internally without introducing contaminants from fuel or electrodes.

- If your primary focus is melting large volumes of steel scrap at low cost: An electric arc furnace is often the more economical and robust choice for bulk processing.

- If your primary focus is uniform, slow heating of a sample in a lab: A resistive tube furnace provides excellent thermal stability, even if it lacks the speed of induction.

Understanding these fundamental principles allows you to select the precise heating technology that aligns perfectly with your material and process goals.

Summary Table:

| Principle | How It Generates Heat | Key Materials Affected |

|---|---|---|

| Joule Heating | Electrical resistance to induced eddy currents generates intense heat. | All conductive metals (e.g., Copper, Aluminum, Steel) |

| Magnetic Hysteresis | Internal friction from realigning magnetic domains creates supplemental heat. | Ferromagnetic metals (e.g., Iron) until the Curie point |

Ready to achieve superior metal melting with precision and purity?

KINTEK specializes in advanced lab equipment, including induction furnaces designed for clean, efficient, and highly controlled melting processes. Whether you're in R&D, aerospace, or metallurgy, our solutions ensure high-purity results without contamination.

Contact our experts today to find the perfect induction heating solution for your laboratory's specific needs.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a tube furnace? Achieve Precise High-Temperature Processing in a Controlled Atmosphere

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- What temperature is alumina activated? Unlock Optimal Porosity for Adsorption