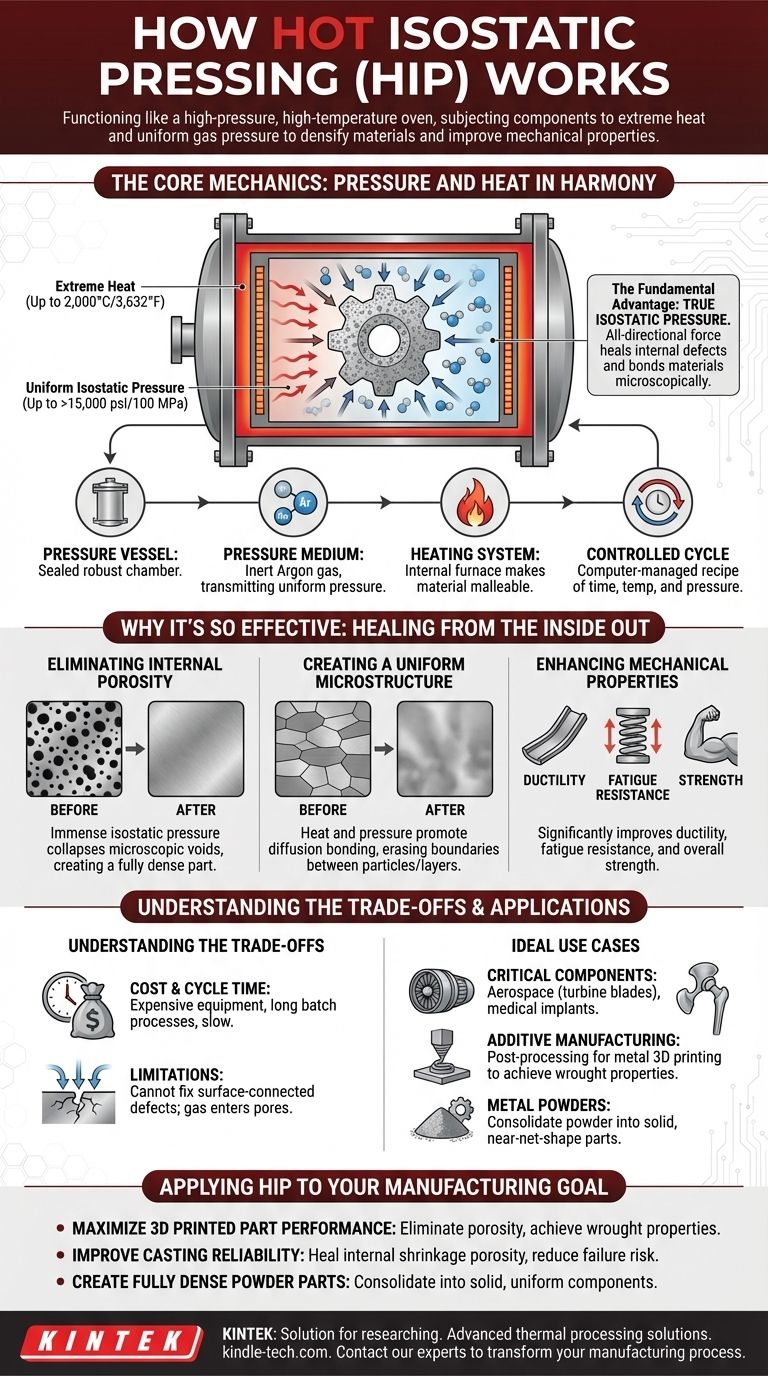

Hot Isostatic Pressing (HIP) is a sophisticated industrial process that functions like a high-pressure, high-temperature oven. It simultaneously subjects components to extreme heat and uniform gas pressure from all directions. This combined action effectively squeezes out internal microscopic defects like pores or voids, densifying the material and significantly improving its mechanical properties.

The fundamental advantage of Hot Isostatic Pressing is its use of truly uniform, or isostatic, pressure. This all-directional force allows it to heal internal defects and bond materials on a microscopic level in a way that directional, mechanical pressing simply cannot achieve.

The Core Mechanics: Pressure and Heat in Harmony

The HIP process takes place inside a specialized piece of equipment and follows a precise, computer-controlled cycle. It combines three critical elements to transform the internal structure of a part.

The Pressure Vessel

Components are loaded into a sealed, robust chamber designed to withstand immense internal pressure and temperature. This vessel acts as the container for the entire process.

The Pressure Medium

The chamber is filled with a chemically inert gas, most commonly argon. This gas is then pressurized to levels often exceeding 15,000 psi (100 MPa). This gas acts as a fluid, transmitting pressure equally and uniformly over the entire surface of the component, regardless of its geometric complexity.

The Heating System

An internal furnace within the pressure vessel heats the components to very high temperatures, often up to 2,000°C (3,632°F). This heat softens the material, making it malleable enough for the high pressure to effectively close internal voids.

The Controlled Cycle

A computer controls the entire cycle, managing the ramp-up of temperature and pressure, the "soak" time where the component is held at peak conditions, and the controlled cool-down. This specific recipe of time, temperature, and pressure is tailored to the material and the desired final properties.

Why It's So Effective: Healing from the Inside Out

The true value of HIP lies in its ability to fundamentally improve a material's internal structure. It doesn't just treat the surface; it re-engineers the component from its core.

Eliminating Internal Porosity

For components made through casting or additive manufacturing (3D printing), microscopic voids are a common and critical weakness. The immense isostatic pressure physically collapses these voids, forcing the material to bond together and creating a fully dense part.

Creating a Uniform Microstructure

The combination of heat and pressure promotes diffusion bonding. At a microscopic level, atoms move between the surfaces of internal particles or layers, effectively erasing the boundaries between them. This turns a part with potential internal weaknesses into a uniform, monolithic solid.

Enhancing Mechanical Properties

By eliminating defects and unifying the microstructure, HIP dramatically improves a part's performance. The result is a significant increase in ductility (the ability to deform without fracturing), fatigue resistance, and overall strength.

Understanding the Trade-offs

While powerful, HIP is a specific tool for specific challenges. Understanding its limitations is key to using it effectively.

Ideal Use Cases

HIP is essential for high-performance, critical components where failure is not an option. This includes aerospace parts like turbine blades, medical implants, and tools where maximum durability is required. It is a vital post-processing step for metal 3D printing to achieve properties comparable to traditionally forged materials.

The Primary Limitation: Cost and Cycle Time

HIP is a batch process that can be slow and energy-intensive. The equipment is expensive, and cycle times can last for many hours. This makes it unsuitable for high-volume, low-cost components where minor internal porosity is not a functional concern.

When HIP Cannot Help

The process can only fix internal, isolated defects. It cannot fix any flaw that is connected to the part's surface, as the pressurized gas would simply enter the crack or pore instead of closing it.

Applying HIP to Your Manufacturing Goal

The decision to use Hot Isostatic Pressing should be driven by your final performance requirements.

- If your primary focus is maximizing the performance of 3D printed metal parts: Use HIP to eliminate porosity between printed layers and achieve material properties comparable to a solid, wrought block.

- If your primary focus is improving the reliability of critical metal castings: Apply HIP to heal internal shrinkage porosity, dramatically reducing the risk of unexpected part failure under stress.

- If your primary focus is creating fully dense parts from metal powders: Use HIP to consolidate the powder into a solid, near-net-shape component with superior and highly uniform material properties.

Ultimately, Hot Isostatic Pressing transforms a component from a collection of joined particles or grains into a truly monolithic and highly reliable solid.

Summary Table:

| Key Element | Function in the HIP Process |

|---|---|

| Pressure Vessel | A sealed, robust chamber that contains the component and withstands extreme conditions. |

| Pressure Medium (Argon Gas) | Transmits uniform, isostatic pressure (often >15,000 psi) from all directions to collapse internal voids. |

| Internal Furnace | Heats the component (up to 2000°C) to make the material malleable for effective densification. |

| Primary Benefit | Creates a fully dense, monolithic part by eliminating porosity and promoting diffusion bonding. |

| Ideal Applications | Critical components for aerospace, medical implants, and post-processing for metal 3D printing. |

Ready to achieve superior material performance and part reliability?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing systems. Our HIP equipment is designed to help manufacturers in aerospace, medical, and additive manufacturing eliminate internal defects, enhance mechanical properties, and ensure the utmost reliability of their critical components.

Contact our experts today to discuss how HIP can transform your manufacturing process and deliver the high-performance parts your applications demand.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What role does the pressure system of a vacuum hot pressing furnace play? Optimize Ti-Al Laminated Composite Density

- What advantages does a vacuum hot press furnace offer over conventional pressureless sintering for NiCr-Al2O3? Find Out

- Why is it necessary to maintain a high vacuum environment during the hot pressing and sintering of CuCrFeMnNi alloys?

- What role does a Vacuum Hot Press perform in the densification of Mg3Sb2? Achieve 96%+ Density with VHP

- What are the benefits of using a Spark Plasma Sintering (SPS) furnace compared to cold pressing? Boost LLTO Density

- What is SPS and its advantages? A Fast, Efficient Method for High-Performance Materials

- How does a vacuum hot pressing sintering furnace facilitate TiBw/TA15 synthesis? Achieve 100% Dense Titanium Composites

- What pressurization methods are employed in a vacuum hot pressing furnace? Choose the Right Method for Your Materials