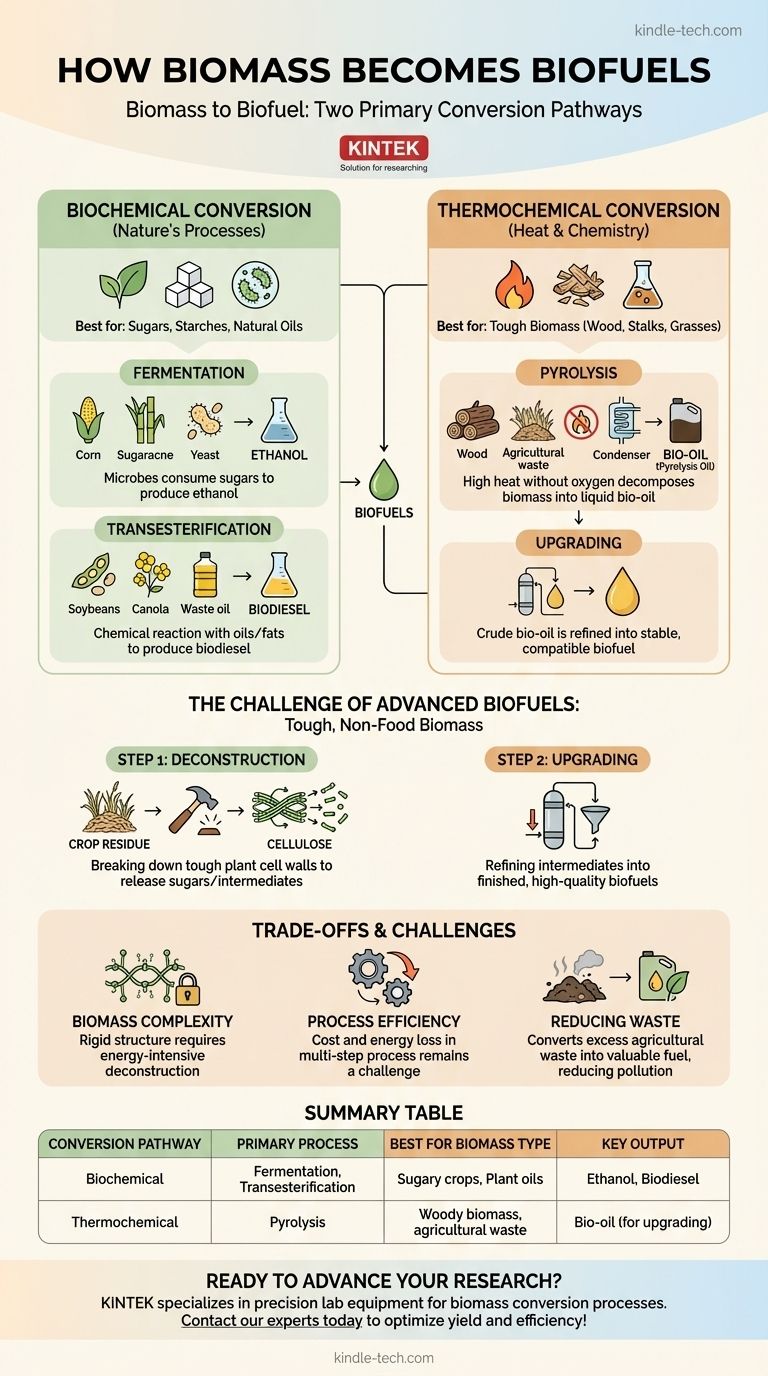

To convert biomass into biofuels, two primary pathways are used: biochemical and thermochemical. Biochemical methods, like fermentation, use microorganisms to break down plant sugars into fuels like ethanol. Thermochemical methods, like pyrolysis, use heat in the absence of oxygen to decompose biomass into a liquid known as bio-oil.

The core principle is that no single conversion method fits all types of biomass. The right process—whether it's biological fermentation or heat-based pyrolysis—is determined by the chemical makeup of the starting material and the desired final fuel.

The Two Primary Conversion Pathways

Understanding how biomass becomes fuel requires separating the methods into two distinct categories. One leverages biology, while the other leverages heat and chemistry.

Biochemical Conversion: Using Nature's Processes

This pathway uses enzymes and microorganisms to do the conversion work. It is most effective for biomass that is rich in sugars, starches, or natural oils.

The most common biochemical process is fermentation. In this method, microbes (like yeast) consume simple sugars from crops like corn or sugarcane and produce ethanol as a byproduct.

Another key process is transesterification. This chemical reaction is used to produce biodiesel from oils and fats found in sources like soybeans, canola, or even waste vegetable oil.

Thermochemical Conversion: Using Heat and Chemistry

This pathway uses high temperatures and chemical catalysts to break down the entire structure of the biomass, making it suitable for tougher materials like wood, agricultural stalks, or grasses.

The primary thermochemical process is pyrolysis. Biomass is heated rapidly to high temperatures in an oxygen-free environment. Instead of burning, it decomposes into a mix of gases, which are then rapidly cooled and condensed into a liquid bio-oil, also called pyrolysis oil.

This bio-oil is a dense, crude intermediate that can be further processed or "upgraded" to produce more refined fuels.

The Challenge of Advanced Biofuels

Converting simple sugars or plant oils is relatively straightforward. The real challenge, and the focus of advanced biofuel production, lies in using tough, non-food biomass like crop residue or wood.

Step 1: Deconstruction

This material is primarily composed of cellulose, a rigid plant fiber that is difficult to break down. The first step, deconstruction, uses heat, chemicals, or enzymes to dismantle these tough plant cell walls.

The goal of deconstruction is to release the valuable sugars and other chemical intermediates locked inside the plant fiber.

Step 2: Upgrading

Once deconstructed, the resulting intermediates—whether they are crude bio-oils from pyrolysis or sugars from cellulosic breakdown—are not yet finished fuels.

They must be upgraded. This is a refining stage where impurities are removed and the chemical structure of the liquid is altered to create a stable, high-quality biofuel compatible with existing engines.

Understanding the Trade-offs and Challenges

The primary goal of biofuel conversion is to transform bulky, inconvenient solid biomass into a dense, easily transportable liquid fuel. However, the process is not without its difficulties.

Biomass Complexity

The main obstacle is the rigid structure of plant biomass. While starch from a corn kernel is easy for microbes to access, the cellulose in a corn stalk is chemically locked away, requiring the energy-intensive deconstruction step.

Process Efficiency

Each conversion step, from deconstruction to upgrading, has an associated cost and potential for energy loss. Achieving an affordable and efficient multi-step process for advanced biofuels remains a significant engineering challenge.

Reducing Waste

A key driver for this technology is solving environmental problems, such as the pollution caused by burning excess agricultural waste. Converting this waste into fuel provides a valuable alternative to open-field burning.

Matching the Process to the Goal

Choosing the correct conversion technology depends entirely on your starting material and your desired end product.

- If your primary focus is converting sugary or starchy crops (like corn or sugarcane): Biochemical fermentation is the most direct and established pathway to produce ethanol.

- If your primary focus is converting plant oils or waste grease: Biochemical transesterification is the standard industrial process for creating biodiesel.

- If your primary focus is converting tough, non-food biomass (wood, switchgrass, or agricultural stalks): A thermochemical process like pyrolysis or a multi-step deconstruction-and-upgrading approach is necessary.

Ultimately, mastering these conversion technologies is essential for turning abundant, low-value biomass into a valuable source of renewable energy.

Summary Table:

| Conversion Pathway | Primary Process | Best For Biomass Type | Key Output |

|---|---|---|---|

| Biochemical | Fermentation, Transesterification | Sugary crops (corn), plant oils | Ethanol, Biodiesel |

| Thermochemical | Pyrolysis | Woody biomass, agricultural waste | Bio-oil (for upgrading) |

Ready to advance your biofuel research or production? KINTEK specializes in precision lab equipment and consumables essential for biomass conversion processes, from pyrolysis reactors to fermentation monitoring systems. Our solutions help you optimize yield and efficiency. Contact our experts today to find the right tools for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- What is the most commonly used autoclave? Discover the Industry Standard for Sterilization

- Why is autoclave temperature 134? Achieve Rapid Sterilization for Critical Instruments

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization

- What autoclave is used for sterilization? The Definitive Guide to Steam Sterilization