Calculating filter press capacity involves more than just the physical size of the equipment. The primary calculation determines the total chamber volume, but the true measure of performance—the solids throughput over time—depends heavily on the specific characteristics of your slurry and your operational cycle time.

The essential distinction to understand is between theoretical volumetric capacity and actual operational throughput. While a press has a fixed chamber volume, its ability to process solids per hour is a dynamic variable determined entirely by slurry properties and cycle times.

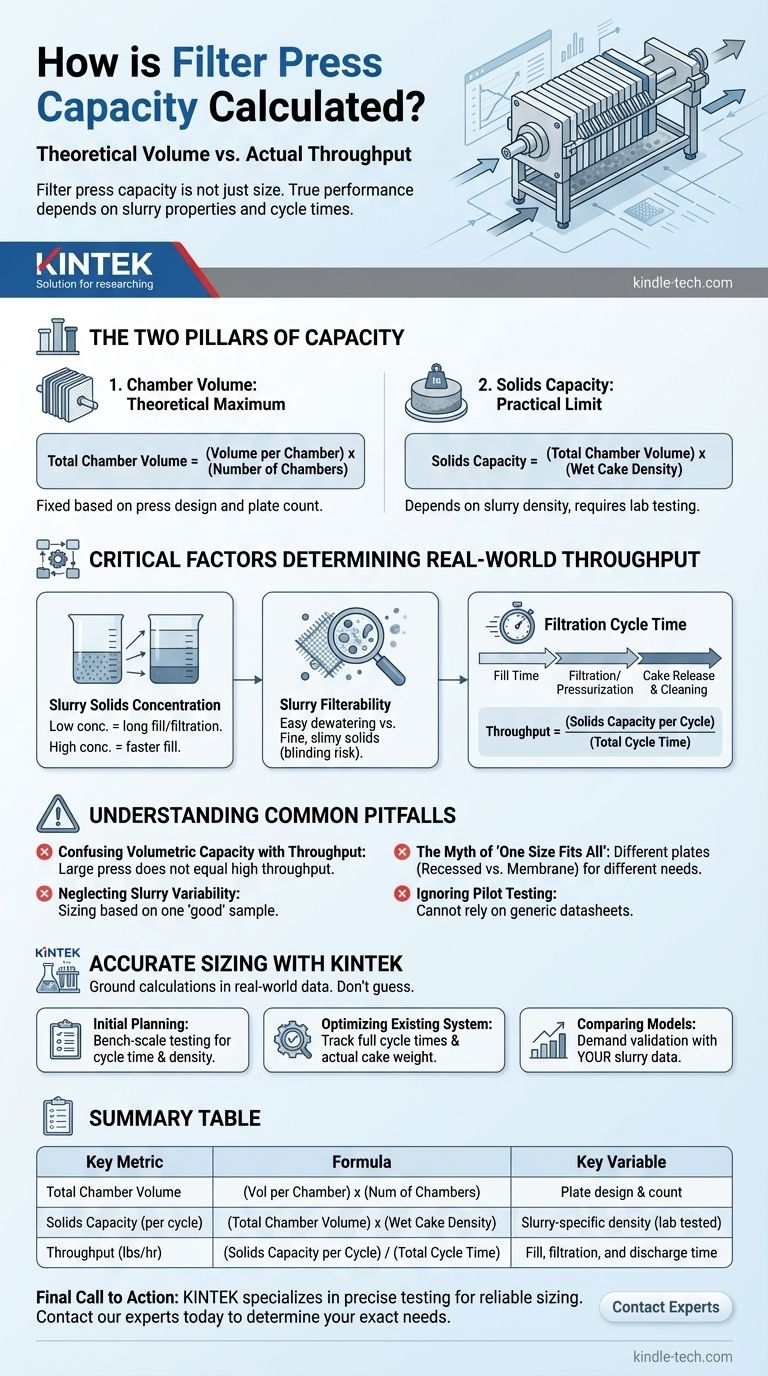

The Two Pillars of Filter Press Capacity

To properly assess capacity, you must calculate both the static volume of the press and the practical amount of solids it can hold.

Chamber Volume: The Theoretical Maximum

The most basic capacity metric is the total internal volume available to form filter cakes. This is a fixed value based on the press's design.

The calculation is straightforward: Total Chamber Volume (ft³ or m³) = (Volume per Chamber) x (Number of Chambers)

The volume per chamber is a specification provided by the manufacturer, determined by the plate thickness and design. The number of chambers is one less than the number of plates.

Solids Capacity: The Practical Limit

More important than raw volume is the dry weight of solids the press can capture in a single cycle. This depends on how densely the solids pack together.

The calculation for solids capacity is: Solids Capacity (lbs or kg) = (Total Chamber Volume) x (Wet Cake Density)

Wet Cake Density is a critical, slurry-specific variable. It represents the weight of the dewatered cake per unit of volume and can only be accurately determined through lab testing of your material.

Critical Factors That Determine Real-World Throughput

A press's volumetric capacity is constant, but its throughput (e.g., tons per hour) is highly variable. Understanding these factors is the key to accurate sizing and optimization.

Slurry Solids Concentration

The percentage of solids in the feed slurry is paramount. A low-concentration slurry (e.g., 2% solids) contains a vast amount of water that must be filtered out, leading to very long fill and filtration times. A higher concentration slurry (e.g., 20% solids) will fill the press with solids much faster.

Slurry Filterability

This refers to how easily water passes through the solid particles. Large, crystalline particles are easy to dewater. Fine, slimy, or biological solids can blind the filter cloth, dramatically increasing the time required to achieve a dry cake.

The Filtration Cycle Time

Throughput is not just about how much a press holds, but how quickly it can complete a cycle. Total cycle time is the sum of several distinct phases:

- Fill Time: The time it takes to pump slurry into all the chambers.

- Filtration/Pressurization Time: The time spent applying pressure to force water out and form a solid cake. This is often the longest and most variable part of the cycle.

- Cake Release & Cleaning: The time needed to open the press, ensure all cakes have discharged, and prepare the cloths for the next cycle.

The total throughput is calculated as: Throughput (lbs/hr or kg/hr) = (Solids Capacity per Cycle) / (Total Cycle Time in hours)

Understanding the Trade-offs and Common Pitfalls

Basing a decision solely on a manufacturer's listed "capacity" is a common and costly mistake.

Confusing Volumetric Capacity with Throughput

The most frequent error is assuming a press with a large chamber volume will automatically have high throughput. A large press processing a difficult-to-filter slurry with a 4-hour cycle time will be outperformed by a smaller press that can cycle the same material in 1 hour.

Neglecting Slurry Variability

Process streams are rarely perfectly consistent. Sizing a filter press based on a single "good" sample can lead to a system that is undersized for more challenging process conditions, creating a bottleneck in your entire operation.

The Myth of "One Size Fits All"

Different plate technologies exist for a reason. Recessed chamber plates are simple and robust. Membrane filter plates add an extra "squeeze" step that can significantly reduce cycle time and produce a drier cake, but at a higher capital cost. The right choice depends entirely on your slurry and operational goals.

Ignoring the Importance of Pilot Testing

You cannot accurately calculate cycle time or final cake density from a datasheet. The only reliable way to determine these critical variables is through bench-scale or on-site pilot testing with a representative sample of your actual slurry. This is a non-negotiable step for any significant investment.

How to Accurately Size Your Filter Press

To move from a rough estimate to a reliable specification, you must ground your calculations in real-world data from your specific process.

- If your primary focus is initial planning: Obtain a representative slurry sample and engage a vendor or lab for bench-scale testing. This will give you the essential data—cycle time, cake density, and final cake moisture—needed for an accurate calculation.

- If your primary focus is optimizing an existing system: Meticulously track your full cycle times and measure the actual weight and volume of your discharged cakes. This will reveal your true solids capacity and highlight bottlenecks, such as slow filtration or long discharge times.

- If your primary focus is comparing different press models: Demand that any capacity or throughput claims be validated with test data from your slurry, not just generic or theoretical values.

An accurate capacity calculation is not a single number, but a comprehensive model of how your unique material will perform in a specific piece of equipment.

Summary Table:

| Key Metric | Formula | Key Variable |

|---|---|---|

| Total Chamber Volume | (Volume per Chamber) x (Number of Chambers) | Plate design & count |

| Solids Capacity (per cycle) | (Total Chamber Volume) x (Wet Cake Density) | Slurry-specific density from lab testing |

| Throughput (e.g., lbs/hr) | (Solids Capacity per Cycle) / (Total Cycle Time) | Fill, filtration, and discharge time |

Stop guessing your filter press capacity.

Accurate sizing is critical to avoid bottlenecks and ensure your dewatering process meets production goals. The calculations depend entirely on your specific slurry properties—something generic datasheets can't provide.

KINTEK specializes in lab equipment and consumables for precise testing. We help laboratories and process engineers like you determine the exact wet cake density and cycle times needed for reliable filter press sizing through bench-scale testing.

Contact our experts today to discuss your slurry characteristics and get the accurate data you need for a successful investment.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the number one cause of failure in hydraulic systems? The Silent Killer of Your Equipment

- What are the failures in a hydraulic system? Prevent Costly Downtime with Expert Diagnosis

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid