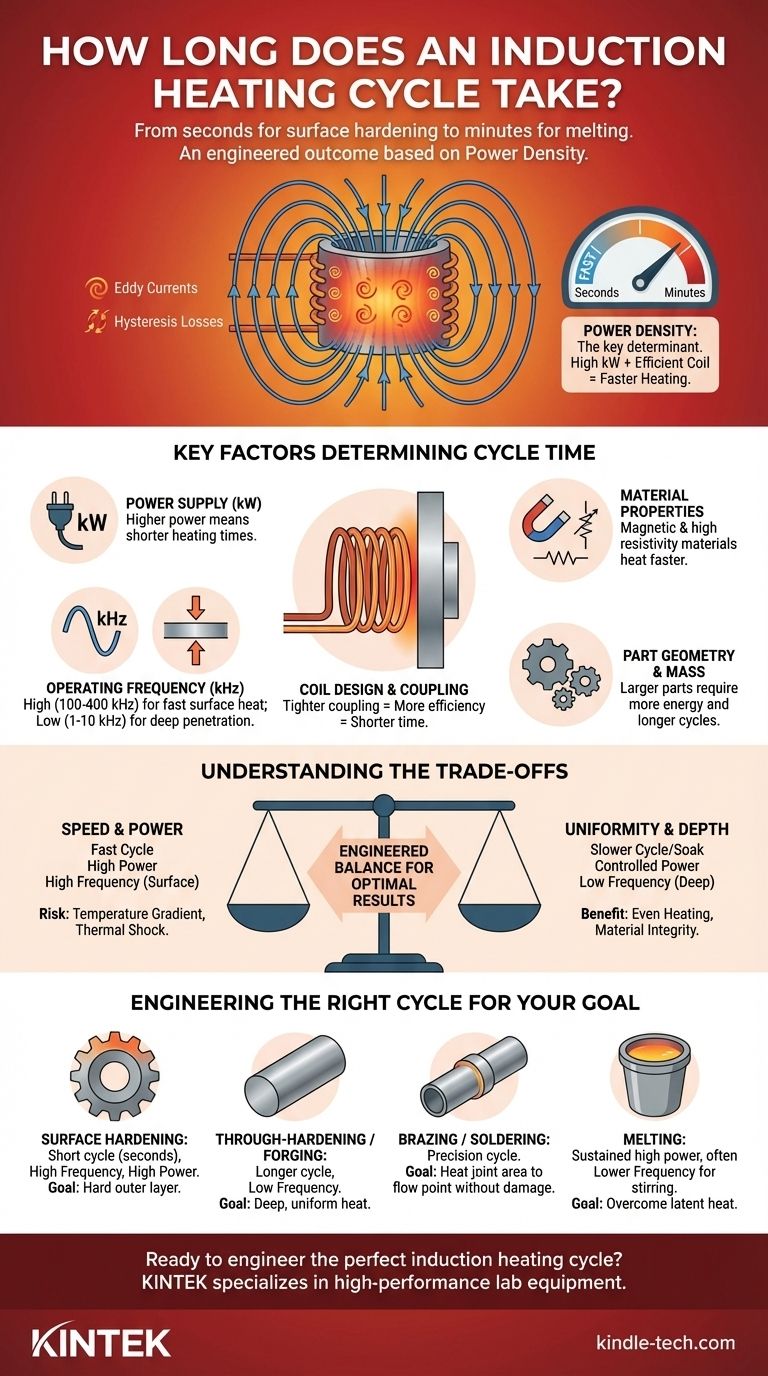

The time required for an induction heating cycle can range from less than a second for surface hardening small components to several minutes for melting large volumes of metal. This duration is not a fixed value but is a direct result of the power applied, the properties of the material being heated, the part's geometry, and the specific goals of the heating process.

Induction heating cycle time is not a given; it is an engineered outcome. The speed is primarily determined by the power density you can deliver to the part, which is a function of the induction system's power, frequency, coil design, and the material's specific properties.

The Core Principle: It's All About Power Density

To understand cycle time, you first need to understand how induction heating works. It’s not about slow, ambient heat transfer; it’s about generating heat directly inside the part itself.

How Induction Delivers Energy

An induction coil generates a powerful, alternating magnetic field. When a conductive part (like metal) is placed inside this field, two things happen:

- Eddy Currents: The magnetic field induces electrical currents that swirl within the part. The material's natural electrical resistance causes these currents to generate precise, intense heat.

- Hysteresis Losses: In magnetic materials (like steel), the rapidly changing magnetic field also causes molecular friction, which generates additional heat. This effect stops once the material passes its Curie temperature and loses its magnetic properties.

Defining Power Density

Power density is the amount of power delivered per unit of surface area. Higher power density means more energy is being transferred to the part in a shorter amount of time, resulting in faster heating. A high-kilowatt power supply coupled with an efficient coil can achieve extremely high power density.

Why Speed is a Key Advantage

This ability to generate instant, internal heat is induction's primary advantage. It allows for incredibly fast and repeatable heating cycles, making it ideal for high-volume manufacturing lines where process time is critical.

Key Factors Determining Heating Time

The final cycle time is a result of several interconnected variables. Understanding these factors is key to engineering the right process.

Power Supply (kW)

This is the most straightforward factor. The kilowatt (kW) rating of your induction power supply dictates the total amount of energy available. A 50 kW system will heat a part much faster than a 10 kW system, assuming all other factors are equal.

Operating Frequency (kHz)

Frequency determines the depth of heat penetration, a phenomenon known as the skin effect.

- High Frequency (e.g., 100-400 kHz): Induces shallow currents, concentrating heat near the surface. This is ideal for rapid surface hardening where the core must remain soft.

- Low Frequency (e.g., 1-10 kHz): Induces deeper currents, allowing heat to penetrate further into the part. This is used for applications like through-hardening, forging, or melting.

Material Properties

The material of the workpiece has a massive impact.

- Magnetic Permeability: Magnetic materials like carbon steel heat far more efficiently below their Curie temperature (around 770°C / 1420°F) due to hysteresis losses.

- Electrical Resistivity: Materials with higher electrical resistance generate more heat from the induced eddy currents (I²R heating).

Part Geometry and Mass

A larger, more massive part requires more total energy to reach a target temperature, naturally leading to a longer heating cycle. The part's shape also influences how effectively the magnetic field can "couple" with it, affecting energy transfer efficiency.

Coil Design and Coupling

The induction coil is the "applicator" that delivers the energy. Its design is critical. The distance between the coil and the workpiece, known as the coupling distance, is especially important. A smaller gap results in a much more efficient energy transfer and a shorter heating time.

Understanding the Trade-offs

Achieving the fastest possible cycle time is not always the primary goal. You must balance speed against other critical process requirements.

Speed vs. Temperature Uniformity

Heating a part extremely quickly creates a significant temperature differential between the hot surface and the cooler core. For applications like forging, you may need a slower cycle with a "soak" time to allow the heat to conduct evenly throughout the part.

Frequency vs. Heat Depth

You cannot simply use the highest frequency for the fastest time. If your goal is to heat the entire part through, using a high frequency is extremely inefficient. You must match the frequency to the required heating depth and the material's properties.

Power vs. Part Integrity

Applying too much power too quickly can induce thermal shock, causing stress, warping, or even cracking in sensitive materials or complex geometries. The cycle must be engineered to respect the material's physical limitations.

Cost vs. Cycle Time

Faster cycle times generally require higher-power equipment, which comes with a higher capital cost. The ideal system is one that meets the required production rate without being oversized and unnecessarily expensive.

Engineering the Right Cycle for Your Goal

The optimal cycle time depends entirely on your application. Your goal should be to find the right balance of the factors above to achieve a repeatable, high-quality result.

- If your primary focus is surface hardening: Your goal is a very short cycle (often seconds) using high frequency and high power to heat only the outer layer.

- If your primary focus is through-hardening or forging: You will use a lower frequency and a longer, controlled cycle to ensure heat penetrates deep into the material's core.

- If your primary focus is brazing or soldering: Cycle time is secondary to precision; the goal is to apply just enough power to heat the joint area to the filler metal's flow point without damaging components.

- If your primary focus is melting: You need a sustained application of high power to overcome the material's latent heat of fusion, often with lower frequencies that induce a stirring effect for alloy uniformity.

Ultimately, induction heating gives you direct control over the heating process, allowing you to engineer the perfect cycle time for your specific application.

Summary Table:

| Factor | Impact on Cycle Time | Key Consideration |

|---|---|---|

| Power Supply (kW) | Higher kW = Shorter Time | Total energy available for heating |

| Frequency (kHz) | High = Fast Surface; Low = Deep Penetration | Matches required heating depth (skin effect) |

| Material Properties | Magnetic materials heat faster below Curie point | Resistivity and permeability affect efficiency |

| Part Geometry & Mass | Larger/more massive parts require longer cycles | Energy needed to reach target temperature |

| Coil Design & Coupling | Tighter coupling = Shorter, more efficient cycles | Distance between coil and part is critical |

Ready to engineer the perfect induction heating cycle for your application?

At KINTEK, we specialize in designing and supplying high-performance lab equipment, including induction heating systems tailored to your specific needs—whether for rapid surface hardening, through-heating, brazing, or melting. Our experts will help you balance speed, uniformity, and cost to achieve optimal, repeatable results.

Contact our team today to discuss your project and discover how KINTEK's solutions can enhance your laboratory's productivity and precision.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- Does induction heating work with copper? Yes, with the right high-frequency equipment.

- What is the effect of frequency to induction hardening? Control Case Depth with Precision

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- Is induction heating more efficient? Achieve Rapid, Precise, and Energy-Saving Heat

- What is the process of induction melting? A Guide to Clean, Efficient Metal Melting

- What are the different types of induction heating? Choose the Right System for Your Melting & Heat Treating Needs

- How do I control the temperature of my induction heater? Master Precise Power & Feedback Control

- What is the primary product manufactured by an electric induction furnace? It's a State of Matter, Not a Final Product