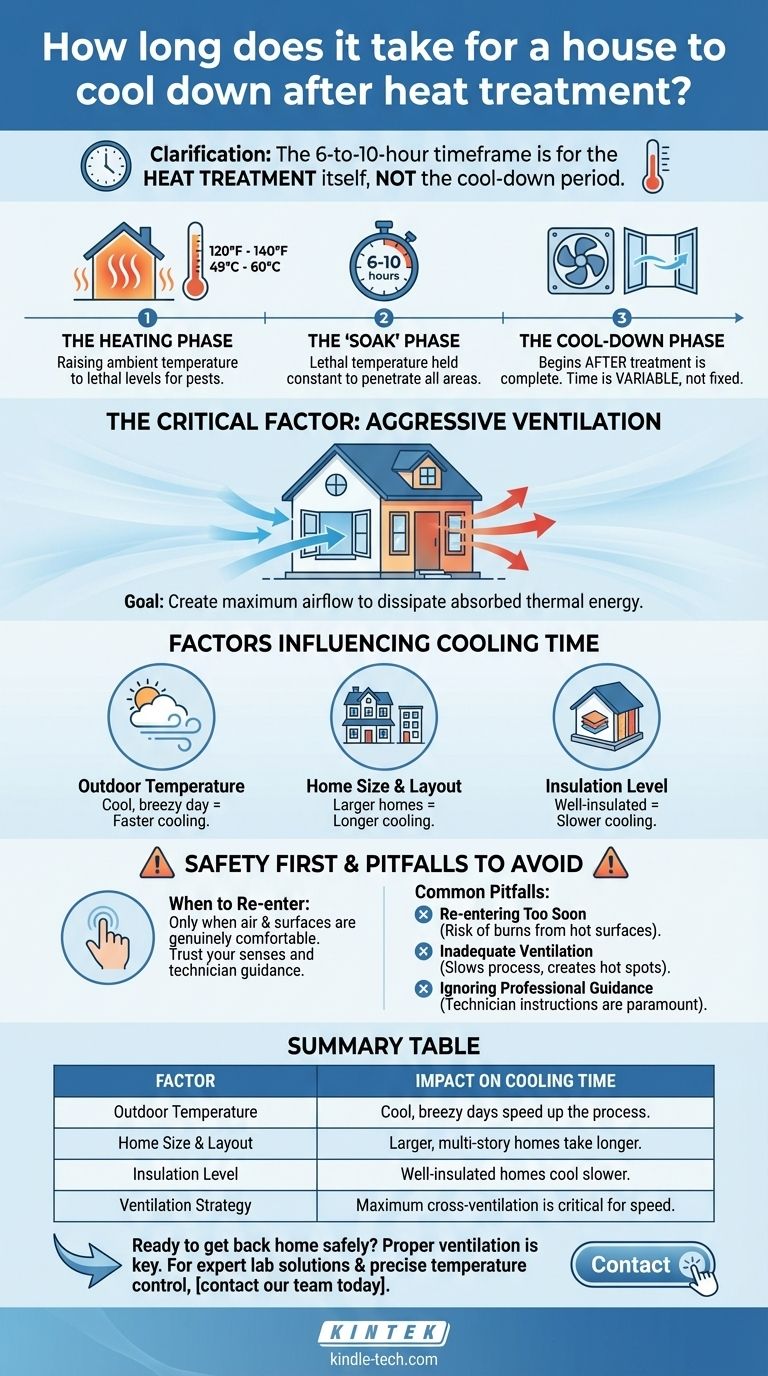

To be clear, the 6-to-10-hour timeframe typically refers to the duration of the heat treatment itself, not the cool-down period. Once the treatment is complete, the process of actively cooling the house begins, and the time it takes for temperatures to return to a safe, tolerable level can vary significantly based on ventilation and outdoor conditions.

The critical factor is not a specific number of hours for cooling, but rather the process of aggressive ventilation. Your goal is to bring the temperature down to a safe and comfortable level, which is achieved by opening windows, doors, and vents to create maximum airflow.

Understanding the Heat Treatment Timeline

A professional heat treatment is a multi-stage process. The cool-down phase is the final, crucial step before you can safely return.

The Heating Phase

Technicians use specialized equipment to raise the ambient temperature in your home to a level that is lethal to pests, typically between 120°F and 140°F (49°C to 60°C).

The "Soak" Phase

This lethal temperature is then held constant for an extended period, often the 6 to 10 hours mentioned. This ensures the heat penetrates every crack, piece of furniture, and wall void to eradicate the entire pest population.

The Cool-Down Phase

This phase begins only after the treatment is officially complete. The equipment is turned off, and the process of returning the house to a habitable temperature starts. The actual time this takes is not a fixed number.

The Critical Cool-Down Process

The speed and safety of the cool-down depend entirely on how efficiently you can move the super-heated air out of your home and replace it with cooler, fresh air.

Why Aggressive Ventilation is Key

Your home's structure, insulation, and furniture have absorbed a massive amount of thermal energy. The only way to dissipate this heat effectively is to create cross-ventilation.

Opening windows and doors on opposite sides of the house allows cool air to push the hot air out, dramatically speeding up the process.

Factors That Influence Cooling Time

Several variables will determine how long the cooling actually takes:

- Outdoor Temperature: A cool, breezy day will cool a house much faster than a hot, still day.

- Home Size & Layout: Larger, multi-story homes will naturally take longer to cool than smaller apartments.

- Insulation: Well-insulated homes, designed to trap heat, will take longer to cool down.

Safety First: When is it Safe to Re-enter?

Do not re-enter until the temperature is genuinely comfortable and tolerable. The surfaces and air can remain dangerously hot for some time after the equipment is off. Trust your senses and the guidance of your pest control technician.

Common Pitfalls to Avoid

Following the correct procedure after the treatment is just as important as the treatment itself.

Re-entering Too Soon

The primary risk is safety. The air temperature may have dropped, but surfaces like furniture, doorknobs, and countertops can still be hot enough to cause burns.

Inadequate Ventilation

If you only open one or two windows, the process will be extremely slow. This creates hot spots and prolongs the time until you can safely return home.

Ignoring Professional Guidance

Your pest control company will provide specific instructions for your situation. Their guidance always supersedes any general advice, as they understand the specifics of the treatment they performed.

How to Approach the Cool-Down Process

Focus on the goal—a safe environment—rather than a specific time on the clock.

- If your primary focus is safety: Wait until the home's ambient temperature feels normal and all surfaces are cool to the touch before moving back in. Always follow the specific instructions from your technician.

- If your primary focus is a speedy return: Open all possible windows, doors, and vents immediately after the technicians give you the all-clear to begin the ventilation process.

Ultimately, proper and thorough ventilation is the only reliable method for ensuring a safe and timely return to your home.

Summary Table:

| Factor | Impact on Cooling Time |

|---|---|

| Outdoor Temperature | Cool, breezy days speed up the process significantly. |

| Home Size & Layout | Larger, multi-story homes take longer to cool. |

| Insulation Level | Well-insulated homes, designed to retain heat, cool slower. |

| Ventilation Strategy | Maximum cross-ventilation (opposite windows/doors) is critical for speed. |

Ready to get back home safely and efficiently? The key to a quick and safe cool-down is proper ventilation. At KINTEK, we understand the importance of precision and safety in all laboratory and treatment processes. While we specialize in lab equipment and consumables for precise temperature control, our commitment to effective results mirrors the diligence needed for your home's recovery. For expert solutions to your specific needs, contact our team today and let us help you achieve your goals with confidence.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the softening temperature of quartz? Ensure Safe & Effective High-Temp Applications

- What are the advantages and disadvantages of a centrifuge? Weighing Speed Against Cost and Risk

- At what temperature do terpenes evaporate? Unlock the Full Flavor and Effects of Your Cannabis

- What would be an advantage of biomass over the use of coal? A Cleaner, Carbon-Neutral Energy Source

- What are three biomass materials that are pelletized? Wood, Agricultural Waste & Energy Crops

- What is the main component of bio-oil? It's a Complex Mixture, Not a Single Chemical

- How is additive manufacturing used in industry? Unlock Complex, Lightweight, and Custom Parts

- How does the use of co-precipitation or impregnation equipment benefit Cu-Ni catalysts? Unlock Atomic-Scale Synergy