Sintering is the critical manufacturing step that transforms a collection of loose powder particles into a dense, solid object with useful mechanical properties. It fundamentally enhances a material's strength, hardness, and wear resistance by heating it below its melting point, causing the individual particles to bond together at an atomic level and progressively eliminate the empty space between them.

The core principle to understand is that sintering isn't just an "on/off" process; it is a highly tunable method for controlling a material's final microstructure. The mechanical properties you achieve are a direct result of balancing key parameters like temperature and time, which always involves navigating critical trade-offs.

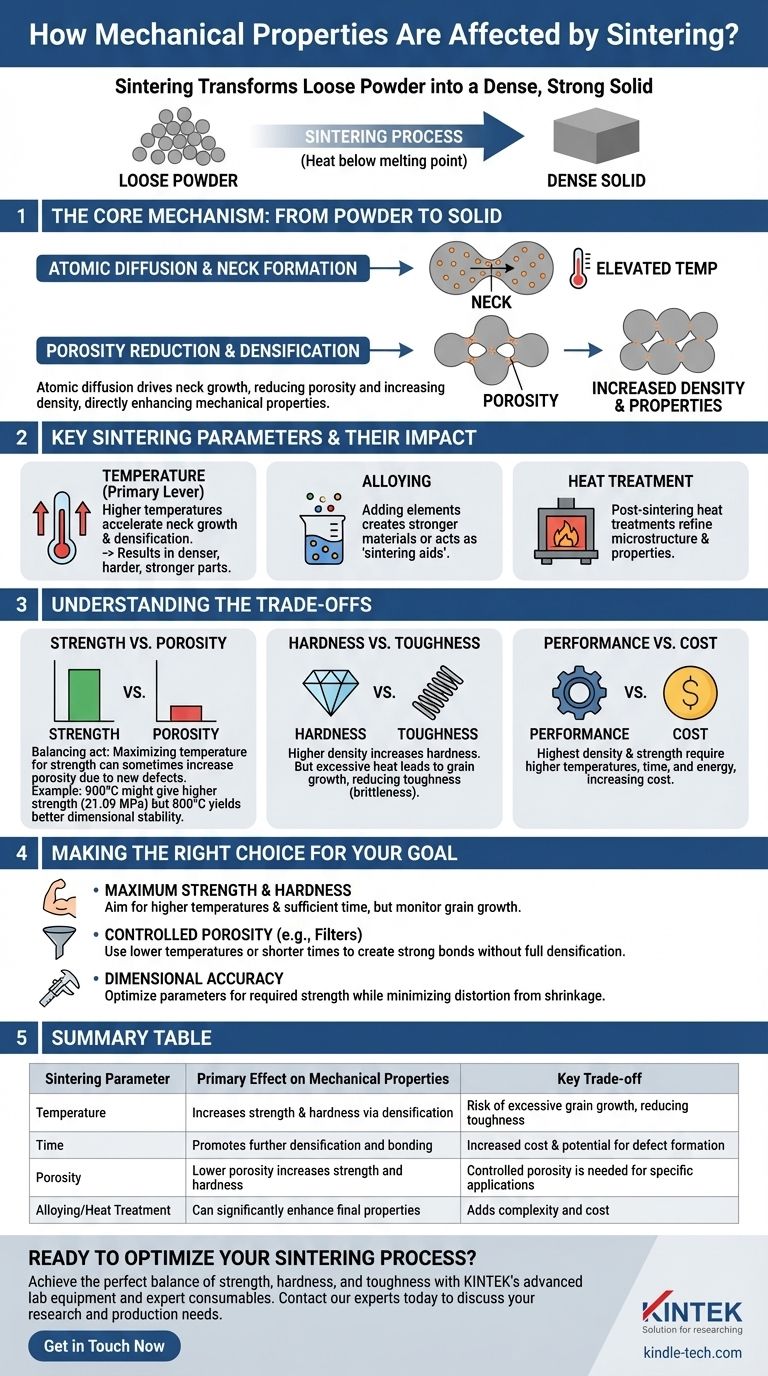

The Core Mechanism: From Powder to Solid

Sintering creates a mechanically strong part by fundamentally altering the material's internal structure. This happens through several distinct but overlapping stages driven by thermal energy.

The Role of Atomic Diffusion

At elevated temperatures, even well below the melting point, atoms in a solid material gain enough energy to move. This movement, or atomic diffusion, is the engine of sintering. Atoms migrate across the surfaces and boundaries of adjacent powder particles, seeking to lower the overall energy of the system.

Neck Formation and Growth

The process begins where particles touch. Atoms diffuse to these contact points, forming small bridges or "necks." These necks are the initial bonds that give the component its early "green" strength. As sintering continues, these necks grow wider and stronger.

Porosity Reduction and Densification

As the necks grow, they pull the centers of the particles closer together. This action systematically closes the gaps and voids (known as porosity) that existed in the original loose powder. The reduction in porosity leads to an increase in the material's density, which is directly correlated with improved mechanical properties.

Key Sintering Parameters and Their Impact

You can precisely control the outcome of sintering by manipulating several key process variables. The most influential of these is temperature.

The Dominant Role of Temperature

Temperature is the primary lever for controlling the rate of diffusion. Higher temperatures provide more energy, accelerating neck growth and densification. This generally results in a denser, harder, and stronger final part.

The Influence of Alloying and Heat Treatment

The composition of the powder itself has a massive impact. Adding other elements, or alloying, can be used to create stronger final materials or to act as "sintering aids" that promote densification at lower temperatures. Subsequent heat treatments after sintering can further refine the microstructure and mechanical properties.

Understanding the Trade-offs

Achieving optimal mechanical properties is not as simple as maximizing temperature. Sintering is a balancing act where improving one property can negatively affect another.

Strength vs. Porosity

As seen with some ceramics, the temperature that yields the highest compressive strength is not always the same temperature that produces the lowest porosity or least shrinkage. For example, a temperature of 900°C might produce a compressive strength of 21.09 MPa, while 800°C yields better dimensional stability. This is because excessive temperatures can introduce new defects even as they reduce porosity.

Hardness vs. Toughness

While higher density generally increases hardness, holding a material at a high temperature for too long can cause its internal crystals, or grains, to grow excessively. Large grains can make a material more brittle, reducing its toughness (its ability to absorb energy and resist fracture).

Performance vs. Cost

Achieving the absolute highest density and strength often requires higher temperatures, longer cycle times, or more complex gas atmospheres. These factors directly increase energy consumption and equipment costs, which must be weighed against the performance requirements of the final component.

Making the Right Choice for Your Goal

To effectively use sintering, you must align your process parameters with the most critical property for your specific application.

- If your primary focus is maximum strength and hardness: Aim for higher sintering temperatures and sufficient time to achieve near-full densification, but monitor for excessive grain growth that could reduce toughness.

- If your primary focus is controlled porosity (e.g., for filters or self-lubricating bearings): Use lower temperatures or shorter times to create strong inter-particle bonds without fully eliminating the desired pore network.

- If your primary focus is dimensional accuracy: Optimize the temperature and time to achieve the required strength while minimizing part distortion from shrinkage, accepting that you may not achieve maximum theoretical density.

By understanding these principles, you can precisely control the sintering process to engineer materials that meet your exact performance requirements.

Summary Table:

| Sintering Parameter | Primary Effect on Mechanical Properties | Key Trade-off |

|---|---|---|

| Temperature | Increases strength & hardness via densification | Risk of excessive grain growth, reducing toughness |

| Time | Promotes further densification and bonding | Increased cost & potential for defect formation |

| Porosity | Lower porosity increases strength and hardness | Controlled porosity is needed for specific applications (e.g., filters) |

| Alloying/Heat Treatment | Can significantly enhance final properties | Adds complexity and cost to the manufacturing process |

Ready to optimize your sintering process for superior material performance?

The principles of sintering are complex, but achieving the perfect balance of strength, hardness, and toughness for your specific application doesn't have to be. KINTEK specializes in providing the advanced lab equipment and expert consumables needed to precisely control every stage of your materials development.

Whether you are developing new metal alloys, advanced ceramics, or composite materials, our solutions help you navigate the critical trade-offs to achieve your mechanical property goals efficiently.

Contact our experts today to discuss how we can support your research and production needs.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the side effects of CBD Distillate? Understanding Mild Effects and Critical Risks

- Why is a multi-step cleaning process involving acetone and ethanol necessary? Ensure Pure Electrode Surface Integrity

- What is in pyrolysis oil? Unlocking the Complex Chemistry of Bio-Oil

- Can brazing be done on stainless steel? Yes, Here's How to Overcome the Oxide Challenge

- What is the effect of power in sputtering? Control Deposition Speed and Film Quality

- What are the physical properties of nitrogen gas? A Guide to Its Power and Invisible Dangers

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- Can pyrolysis generate electricity? Unlock Power from Waste and Biomass