The cost of diamond-like carbon (DLC) is not a fixed price for a material, but a variable cost for a highly technical coating service. This service can range from a few dollars per part for high-volume, simple components to thousands of dollars for a single, complex prototype. The final price is determined by the part's size, the complexity of its geometry, the volume of the production run, and the specific performance requirements of the coating.

The central takeaway is that you are not buying a material, but investing in a manufacturing process. The cost of a DLC coating is driven less by the raw materials and more by the machine time, labor, and engineering expertise required to apply a durable, high-performance film to your specific component.

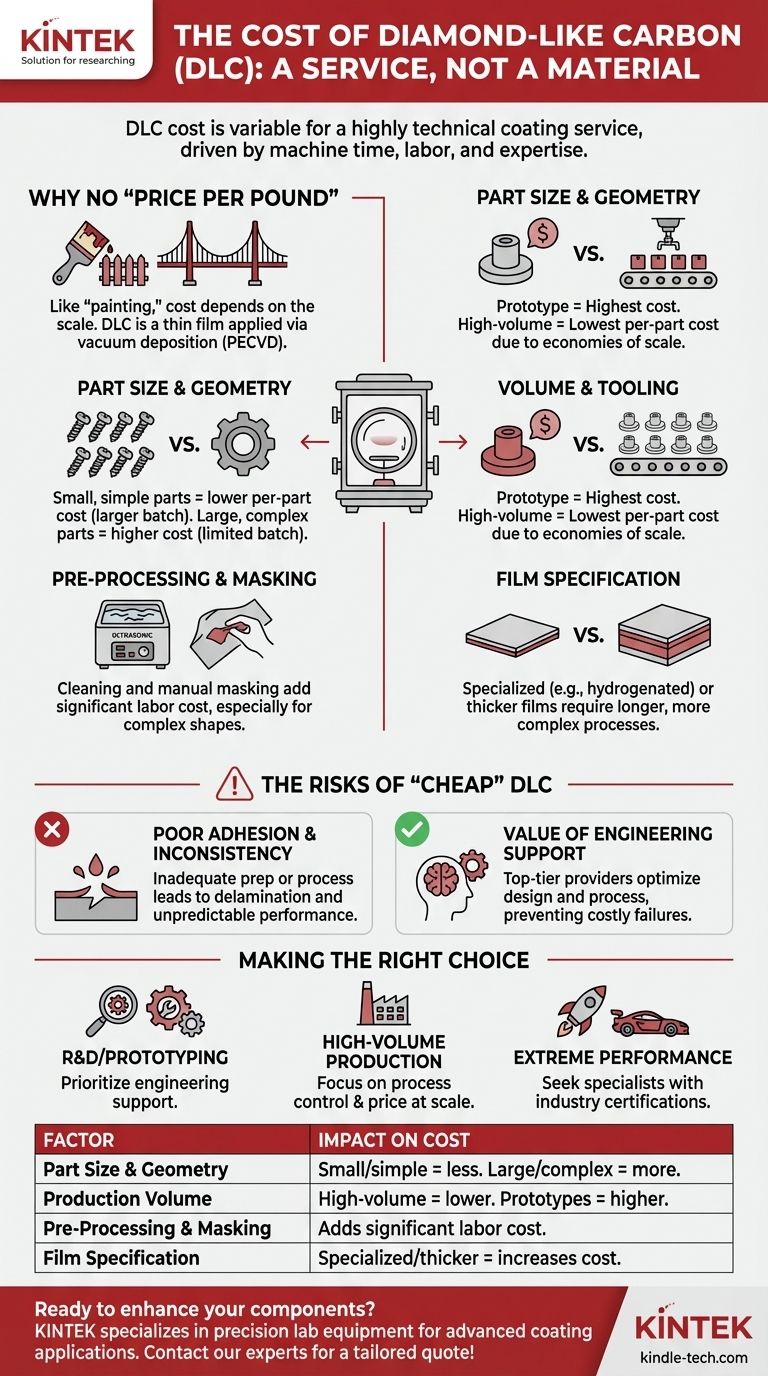

Why There Is No "Price Per Pound" for DLC

Asking for the cost of DLC is like asking for the cost of "painting." The answer depends entirely on whether you're painting a small fence or the Golden Gate Bridge. DLC is a thin film applied to a substrate, and the cost is associated with the service of applying it.

The Core Cost Driver: The Deposition Process

DLC films are applied in a vacuum chamber using advanced deposition methods like Plasma-Assisted Chemical Vapor Deposition (PECVD). This process is the primary factor in its cost.

The cost is a function of machine time. A chamber represents a significant capital investment, and its operating costs (power, vacuum pumps, process gases, maintenance) are high. The more parts you can fit in a single run (or "batch"), the lower the cost per part.

Factor 1: Part Size and Geometry

The physical dimensions of your part directly influence how many can be coated at once.

Small, simple parts like screws or pins can be coated in large quantities in a single batch, leading to a very low per-part cost.

Large or complex parts, like an automotive gear or a unique piece of tooling, take up significant space in the chamber. This limits the batch size, often to just one or a few pieces, dramatically increasing the per-part cost.

Factor 2: Volume and Tooling

Economy of scale is a critical pricing factor.

A one-off prototype is the most expensive scenario. The vendor must account for setup time, engineering review, and the full cost of a machine cycle for a single part.

High-volume production runs (thousands or millions of parts) allow the vendor to optimize the process, create custom fixtures to maximize chamber capacity, and amortize setup costs, resulting in a much lower price per piece.

Factor 3: Pre-Processing and Masking

The DLC film will only adhere to a perfectly clean surface. All parts must undergo a multi-stage, ultrasonic cleaning and drying process before entering the coating chamber.

If only specific areas of your part need coating, the other surfaces must be masked. This is often a manual, labor-intensive process that adds significant cost, especially for complex geometries.

Factor 4: Film Specification

Not all DLC is the same. Different "flavors" of DLC are engineered for specific challenges, and their deposition requirements affect the cost.

A standard, general-purpose DLC might have a shorter cycle time. A highly specialized, hydrogenated, or silicon-doped DLC (for lower friction or higher temperatures) may require a longer, more complex process, increasing the cost. Film thickness also plays a role, as thicker films require more time in the chamber.

Understanding the Trade-offs: Why "Cheap" DLC Can Be Expensive

Choosing a DLC provider based on the lowest quote can lead to significant long-term costs. The price difference between vendors often reflects a difference in process control, quality, and engineering support.

The Risk of Poor Adhesion

The most common failure mode for a DLC coating is delamination or flaking off. This is almost always caused by inadequate surface preparation or improper deposition parameters. A low-cost provider may cut corners on cleaning or rush the process, resulting in a coating that fails prematurely in the field.

The Problem of Inconsistency

Achieving a consistent coating thickness and quality across a single part and from batch to batch requires immense process control. A cheaper service may deliver inconsistent results, leading to unpredictable performance and a higher rate of part rejection.

The Value of Engineering Support

Top-tier coating providers act as partners. They will review your application, suggest the right type of DLC, and help optimize the part design for coating. This expertise is built into their pricing but can prevent costly failures and redesigns down the line.

Making the Right Choice for Your Goal

To get a meaningful quote, you must provide a detailed drawing of your part, specify the material, and state the production volume and performance goals. Approach vendors with this information to get an accurate estimate.

- If your primary focus is R&D or prototyping: Prioritize vendors with strong engineering support who can guide you to the correct coating, even if the cost per part is high.

- If your primary focus is high-volume production: Focus on vendors who can demonstrate robust process control and offer the best per-part price at scale.

- If your primary focus is extreme performance (e.g., aerospace, motorsports): Seek out specialists with a proven track record and certifications in your specific industry.

Ultimately, viewing DLC as a strategic investment in performance, rather than a commodity cost, is the key to leveraging its true value.

Summary Table:

| Factor | Impact on Cost |

|---|---|

| Part Size & Geometry | Small, simple parts cost less per piece. Large, complex parts are more expensive. |

| Production Volume | High-volume runs have a lower per-part cost. Prototypes are more expensive. |

| Pre-Processing & Masking | Complex cleaning and masking requirements add significant labor cost. |

| Film Specification | Specialized DLC types and thicker coatings increase process time and cost. |

Ready to enhance your components with high-performance DLC coatings? At KINTEK, we specialize in precision lab equipment and consumables for advanced coating applications. Our expertise ensures durable, consistent results for your R&D or production needs. Don't leave your project to chance—partner with a trusted supplier. Contact our experts today to discuss your specific requirements and get a tailored quote!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating worth it? Maximize Component Life and Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools