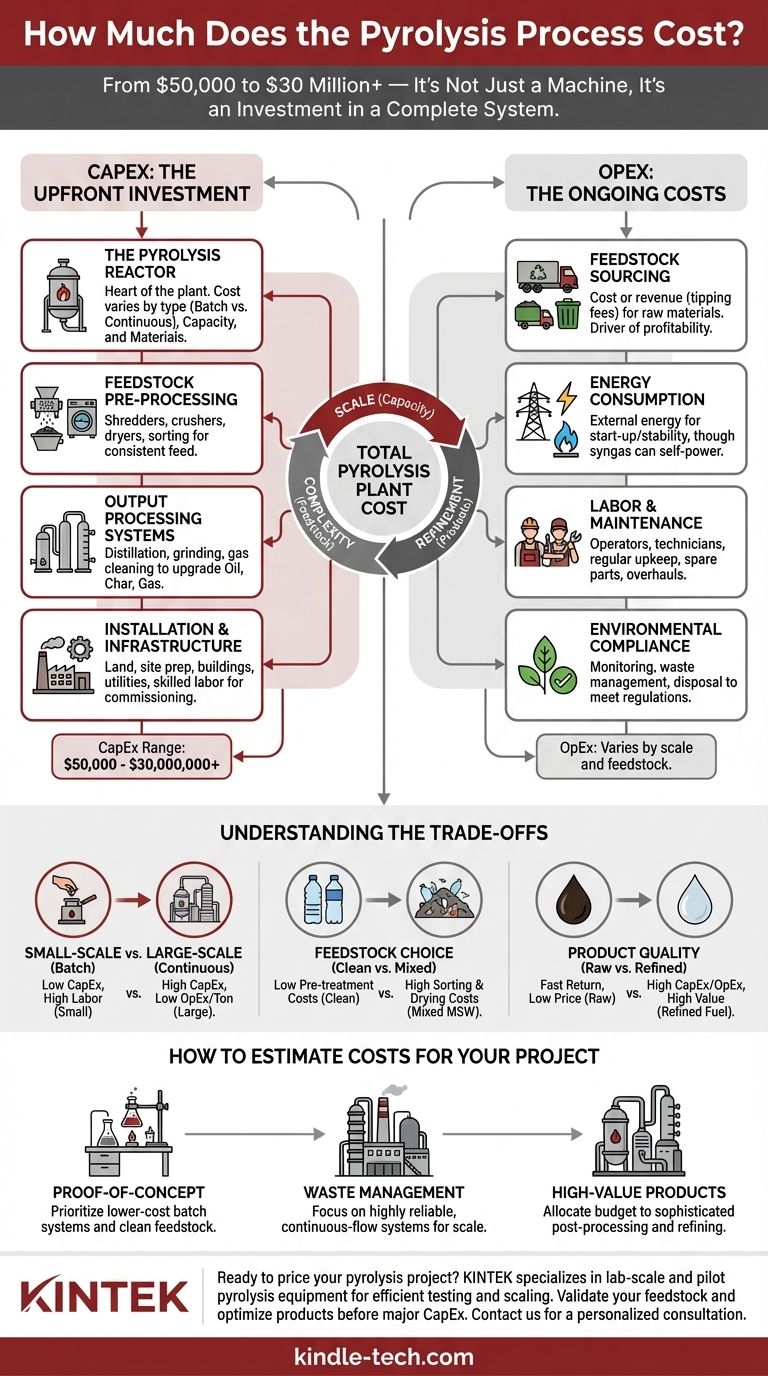

The cost of a pyrolysis plant is not a single number but a vast range, stretching from as little as $50,000 for a small-scale, basic batch system to well over $30 million for a large-scale, continuous industrial facility. This price is fundamentally determined by the plant's capacity, the type of feedstock it processes, and the quality of the final products it is designed to produce.

The crucial insight is that you are not just buying a machine; you are investing in a complete system. The final cost is a direct function of three key variables: the scale of operation, the complexity of handling your specific feedstock, and the degree of refinement required for your target end-products.

The Core Components of Pyrolysis Costs

A pyrolysis project's total cost is divided into two primary categories: the initial, one-time investment (CapEx) and the recurring costs to run the plant (OpEx). Understanding both is essential for a realistic financial assessment.

Capital Expenditures (CapEx): The Upfront Investment

This is the most significant initial outlay and includes all the physical equipment and infrastructure needed to get the plant operational.

The Pyrolysis Reactor

This is the heart of the plant and the single largest cost component. The price varies dramatically based on its type (batch vs. continuous), capacity (measured in tons per day), and materials of construction.

Feedstock Pre-processing Equipment

Raw materials are rarely ready for pyrolysis. You must budget for equipment like shredders or crushers (for plastics, tires), dryers (for wet biomass or sludge), and sorting systems to ensure a consistent feed.

Output Processing Systems

The raw outputs of pyrolysis—oil, gas, and char—often require upgrading to be valuable. This can include distillation units to refine pyrolysis oil into fuel, grinding and bagging systems for biochar, or gas scrubbers to clean syngas for energy generation.

Installation and Infrastructure

This category includes the cost of land, site preparation, buildings, utility connections (electricity, water), and the skilled labor required for engineering, installation, and commissioning the entire plant.

Operational Expenditures (OpEx): The Ongoing Costs

Once the plant is built, you must account for the continuous costs required to keep it running profitably.

Feedstock Sourcing

The cost of your raw material is a primary driver of profitability. This can range from paying for high-quality plastic waste to receiving "tipping fees" for processing municipal solid waste, turning a cost into a revenue stream.

Energy Consumption

While a pyrolysis system can often power itself by using its own non-condensable syngas, it requires an external energy source (like natural gas or electricity) to start up and maintain temperature stability.

Labor and Maintenance

This includes salaries for operators, technicians, and managers. Regular maintenance, spare parts, and periodic overhauls are also significant ongoing expenses that ensure the plant's longevity and safety.

Environmental Compliance

Meeting environmental regulations is non-negotiable. Costs include monitoring emissions, managing wastewater, and properly disposing of any hazardous materials or byproducts that cannot be sold.

Understanding the Trade-offs

The cheapest option upfront is rarely the most profitable long-term. Your business goals must dictate your investment strategy.

Small-Scale vs. Large-Scale

A small, simple batch plant has a low initial CapEx but often requires more manual labor per ton of processed material. A large, fully automated continuous plant has a massive upfront cost but achieves economies of scale, resulting in a much lower operational cost per ton.

The Impact of Feedstock Choice

Processing clean, uniform industrial plastic waste requires minimal pre-treatment, keeping CapEx and OpEx low. Conversely, processing mixed municipal solid waste (MSW) or wet agricultural waste demands complex and expensive sorting and drying systems.

End-Product Quality vs. Revenue

Selling raw, unrefined pyrolysis oil generates the fastest return but fetches the lowest price. Investing in distillation technology to produce a diesel-like fuel requires higher CapEx and OpEx but creates a much more valuable product, dramatically increasing potential revenue.

How to Estimate Costs for Your Project

Your project's specific goals will determine where your budget should be focused.

- If your primary focus is a proof-of-concept or small community project: Prioritize a lower-cost batch system and secure a consistent source of simple, clean feedstock to minimize upfront investment.

- If your primary focus is large-scale waste management: Your model must center on a highly reliable, continuous-flow system designed for feedstock flexibility and minimal labor costs to maximize long-term operational efficiency.

- If your primary focus is producing high-value fuels or chemicals: Allocate a significant portion of your capital budget to sophisticated post-processing and refining technologies, as this is where your product's value is created.

Ultimately, a successful pyrolysis venture is built not on a single price tag, but on a clear understanding of the direct link between your investment, your operational choices, and your final product's market value.

Summary Table:

| Cost Category | Key Components | Typical Range |

|---|---|---|

| Capital Expenditure (CapEx) | Reactor, Pre-processing, Output Systems, Installation | $50,000 - $30,000,000+ |

| Operational Expenditure (OpEx) | Feedstock, Energy, Labor, Maintenance, Compliance | Varies by scale and feedstock |

| Primary Cost Drivers | Plant Capacity, Feedstock Type, End-Product Quality | Determines final investment level |

Ready to accurately price your pyrolysis project? The experts at KINTEK specialize in lab-scale and pilot pyrolysis equipment, helping you test and scale your process efficiently. We provide the reliable equipment and consumables you need to validate your feedstock and optimize your end-products before making a major capital investment. Contact our team today for a personalized consultation and discover how KINTEK can support your pyrolysis venture from concept to reality.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Wall Mounted Water Distillation Unit

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What are the technical characteristics of PTFE (Teflon) lined hydrothermal reactors? Comparing α-ZrP Synthesis Methods

- Why must SCWG reactors maintain a specific heating rate? Protect Your High-Pressure Vessels from Thermal Stress

- Why are high-strength alloy tube reactors critical for HHIP? Ensuring Safety and Purity in High-Pressure Environments

- What is the advantage of using high-pressure hydrothermal reactors to treat biomass waste? Efficient Resource Recovery

- What is the function of a PTFE-lined hydrothermal autoclave in cys-CDs synthesis? Achieve High-Purity Carbon Dots