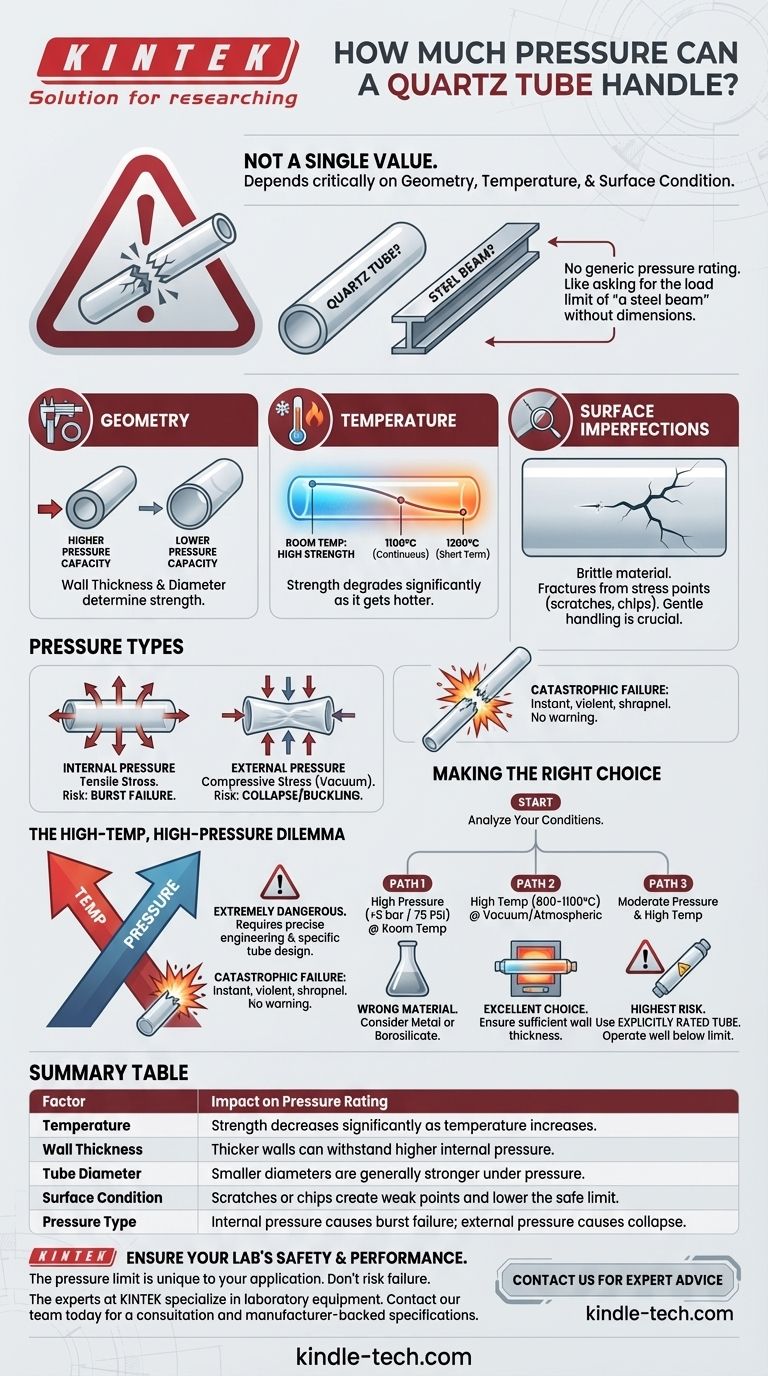

The pressure a quartz tube can handle is not a single value. It is critically dependent on the tube's geometry, operating temperature, and surface condition, meaning a tube that is safe in one application could fail catastrophically in another.

The core takeaway is that you cannot rely on a generic pressure rating for quartz. The actual limit is determined by the tube's specific wall thickness, diameter, and—most importantly—its temperature. Always consult the manufacturer's specifications for your exact tube and apply a significant safety factor.

Why There Is No Single "Pressure Rating"

Attempting to find one pressure rating for "a quartz tube" is like asking for the load limit of "a steel beam." Without knowing the dimensions and conditions, the question is unanswerable. Several interacting factors determine the final strength.

The Critical Role of Geometry

The tube's dimensions are the primary determinant of its strength at any given temperature.

Two key factors are wall thickness and outer diameter. A tube with a thicker wall and a smaller diameter will be substantially stronger and able to withstand much higher internal pressure than a large-diameter, thin-walled tube.

The Overwhelming Impact of Temperature

Quartz is prized for its high-temperature stability, but its mechanical strength degrades significantly as it gets hotter.

While a quartz tube can be used continuously at 1100°C and for short periods up to 1200°C, its strength at these temperatures is a fraction of what it is at room temperature. As you approach its thermal limits, its ability to contain pressure plummets.

The Danger of Surface Imperfections

Quartz is a brittle material. Unlike a metal that might bend or deform under stress, quartz will fracture.

This fracture almost always originates from a stress concentration point, such as a microscopic scratch, chip, or internal impurity. The reference to handling quartz "gently" is not just about preventing immediate breakage; it's about avoiding surface damage that creates a weak point for future failure under pressure or thermal stress.

Internal vs. External Pressure

The type of pressure also matters. Internal pressure creates tensile stress (pulling the material apart), which can lead to a burst failure.

External pressure (a vacuum environment) creates compressive stress. Here, failure often occurs through buckling or collapse, which is heavily dependent on the tube's wall thickness and roundness.

Understanding the Trade-offs and Risks

Using quartz tubes in pressurized systems requires a deep understanding of the material's limitations to ensure safety.

The High-Temperature, High-Pressure Dilemma

The two primary stressors—temperature and pressure—work against each other. The conditions where quartz is most useful (high temperature) are precisely the conditions where it is weakest mechanically.

This makes combining high pressure and high temperature extremely dangerous without precise engineering controls and a tube specifically designed for that purpose.

The Risk of Catastrophic Failure

Because quartz is brittle, it provides no warning before failure. It will not yield or stretch. A failure under pressure is instantaneous, violent, and results in the shattering of the tube.

This presents a significant safety hazard from both the sudden release of pressure and the resulting shrapnel. Proper safety shields and pressure-relief systems are mandatory.

Manufacturer Data Is Non-Negotiable

Never assume a quartz tube is safe for your pressure application based on its dimensions alone.

Reputable manufacturers provide pressure-temperature charts for their specific products. These charts are the only reliable source of information, as they are based on the exact material purity and manufacturing tolerances of the tube.

Making the Right Choice for Your Application

To operate safely, you must shift your thinking from finding a generic number to analyzing your specific operating conditions.

- If your primary focus is high pressure (>5 bar / 75 PSI) at or near room temperature: Quartz is likely the wrong material. Consider a metal or thick-walled borosilicate glass vessel instead.

- If your primary focus is high temperature (800-1100°C) under vacuum or at atmospheric pressure: Quartz is an excellent choice. Ensure the wall thickness is sufficient to prevent collapse under vacuum if applicable.

- If your primary focus is combining moderate pressure and high temperature: This is the highest-risk scenario. You must use a tube explicitly rated by the manufacturer for your target conditions and operate well below the maximum limit.

Ultimately, your safety depends on treating every quartz tube as a unique engineered component with specific, non-transferable limits.

Summary Table:

| Factor | Impact on Pressure Rating |

|---|---|

| Temperature | Strength decreases significantly as temperature increases. |

| Wall Thickness | Thicker walls can withstand higher internal pressure. |

| Tube Diameter | Smaller diameters are generally stronger under pressure. |

| Surface Condition | Scratches or chips create weak points and lower the safe limit. |

| Pressure Type | Internal pressure causes burst failure; external pressure causes collapse. |

Ensure your lab's safety and performance. The pressure limit for your quartz tube is unique to your application's temperature and geometry. Don't risk catastrophic failure. The experts at KINTEK specialize in laboratory equipment and consumables. We can help you select the right quartz tube for your specific high-temperature and pressure needs. Contact our team today for a consultation and get the precise, manufacturer-backed specifications you need for safe operation.

Visual Guide

Related Products

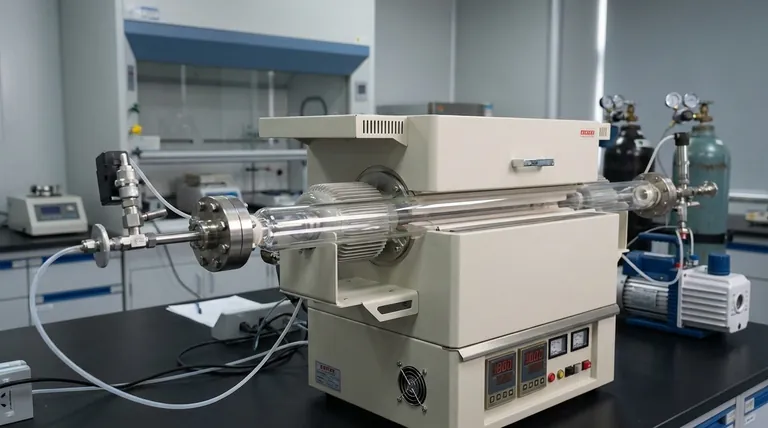

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- Why are high-strength graphite molds used for vacuum hot pressing copper composites? Essential Benefits for Lab Results

- What are the functions of high-purity quartz balls and quartz sand for catalyst testing? Enhance Reactor Performance

- Why use vacuum-sealed quartz ampoules for halide electrolyte synthesis? Ensure Purity & Stoichiometric Accuracy

- How are specialized consumables used to maintain LiMOCl4 stability? Ensure Pure Air-Sensitive Material Processing

- What is the function of a mechanical stirrer in catalyst prep? Ensure Homogeneity in Mixed Oxide Catalyst Supports

- What are the applicable sample dimensions for the sample holder? Ensure a Perfect Fit for Your Lab Samples

- What is the primary function of a quartz glass sample holder in high-temperature corrosion studies? Ensure Data Integrity

- Why Use Zirconia Grinding Media for RPPO Solid Electrolytes? Ensure Purity and Performance