To prepare a pressed powder pellet, you must first grind the sample to a fine, uniform particle size, often with a binding agent. This homogeneous mixture is then poured into a die set and compressed under high pressure using a hydraulic press. The final pellet is carefully ejected for analysis.

The critical insight is that the quality of your final analytical data is determined not by the press itself, but by the meticulous and consistent preparation of the powder before it ever enters the die. Attention to detail in this early stage is non-negotiable for reliable results.

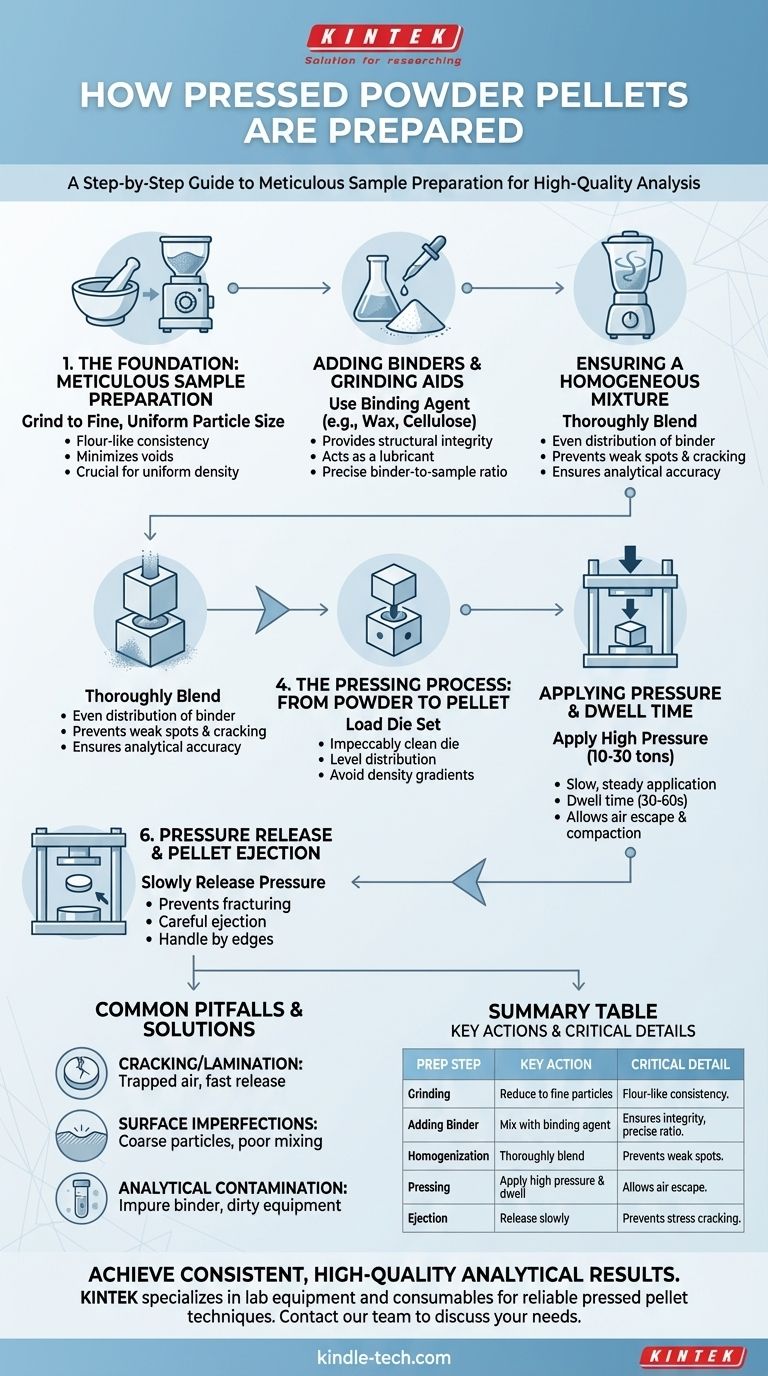

The Foundation: Meticulous Sample Preparation

The most common errors in pellet analysis originate from poor sample preparation. A mechanically sound pellet is the direct result of a well-homogenized powder.

Achieving Particle Size Homogeneity

The first step is to reduce your sample to a fine, flour-like consistency. This is typically done with a high-performance mill or a simple mortar and pestle.

A uniform, small particle size is crucial. It minimizes voids in the final pellet, reduces the effects of particle segregation, and ensures a more uniform density, which is critical for many analytical techniques like XRF.

The Role of Binders and Grinding Aids

Most samples require a binding agent or grinding aid to create a durable pellet that can withstand handling. Common binders include waxes, cellulose, or boric acid.

The binder acts as a lubricant during pressing and provides structural integrity to the finished pellet. The ratio of binder to sample must be precise and consistent from sample to sample to ensure analytical accuracy.

Ensuring a Homogeneous Mixture

Once ground, the sample and binder must be thoroughly blended. This ensures that the binder is evenly distributed throughout the powder.

Inadequate mixing can lead to weak spots, cracking, or an uneven surface on the pellet, all of which compromise the quality of your analysis.

The Pressing Process: From Powder to Pellet

With a properly prepared powder, the pressing stage becomes a controlled, repeatable process. The goal is to compact the powder into a solid disc with a smooth, flat analytical surface.

Loading the Die Set

The die set, consisting of a body, a plunger, and a base, must be impeccably clean. The prepared powder is carefully poured into the die.

It is important to ensure the powder is level before inserting the plunger. An uneven distribution can create density gradients and structural weaknesses in the pellet.

Applying Pressure and Dwell Time

The die is placed in a hydraulic press, and pressure is applied slowly and steadily. The final pressure can range from 10 to 30 tons, depending on the material and die size.

This pressure is typically held for a specific period, known as dwell time (e.g., 30-60 seconds). This allows trapped air to escape and the particles to fully compact, reducing the risk of lamination or cracking.

Pressure Release and Pellet Ejection

Releasing the pressure too quickly is a common cause of pellet failure. The pressure must be released slowly and smoothly to prevent the pellet from fracturing due to internal stresses.

Once the pressure is fully released, the pellet is carefully ejected from the die. It should be handled only by its edges, preferably with tweezers, to avoid contaminating the analytical surface.

Understanding the Trade-offs and Common Pitfalls

Even with a defined method, problems can arise. Understanding why they happen is key to troubleshooting and perfecting your technique.

Pellet Cracking or Lamination

This is the most frequent issue, often caused by trapped air. A slow pressure application, sufficient dwell time, and a slow pressure release are the primary solutions. An incorrect binder-to-sample ratio can also contribute to a weak pellet.

Surface Imperfections

A dull, pockmarked, or uneven surface (sometimes called "orange peel") indicates a problem. This is usually due to particles being too coarse, poor mixing, or a worn or dirty die surface.

Analytical Contamination

The binder itself can be a source of contamination if it contains elements you are trying to measure. Always select a binder that is free of your analytes of interest. Furthermore, cross-contamination between samples can be prevented by rigorously cleaning the die set and grinding equipment after every use.

A Checklist for High-Quality Pellets

Your preparation strategy should be guided by your ultimate analytical goal.

- If your primary focus is high-accuracy quantitative analysis (e.g., XRF): Your top priority is consistency in particle size, sample mass, and the binder-to-sample ratio for every pellet.

- If your primary focus is qualitative identification (e.g., FTIR): Your main concern is selecting the right matrix (like KBr) that is transparent in the infrared region and free of impurities to avoid spectral interference.

- If your primary focus is routine, high-throughput screening: The key is to establish a standardized and documented procedure that every operator can follow precisely to ensure inter-user consistency.

Ultimately, a meticulously prepared pellet is the foundation of trustworthy analytical data.

Summary Table:

| Preparation Step | Key Action | Critical Detail |

|---|---|---|

| Sample Grinding | Reduce to fine, uniform particles | Achieves flour-like consistency for uniform density |

| Adding Binder | Mix with binding agent (e.g., wax, cellulose) | Ensures pellet integrity; ratio must be precise |

| Homogenization | Thoroughly blend powder and binder | Prevents weak spots and uneven surfaces |

| Pressing | Apply high pressure (10-30 tons) with dwell time | Allows air escape and proper compaction |

| Ejection | Release pressure slowly and eject carefully | Prevents cracking from internal stress |

Achieve consistent, high-quality analytical results with every pellet. The precision of your analysis starts with perfect sample preparation. KINTEK specializes in the lab equipment and consumables—including mills, presses, dies, and binders—that laboratories rely on for reliable pressed pellet techniques.

Let our experts help you optimize your preparation workflow. Contact our team today to discuss your specific application needs.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the purpose of the uniaxial pressure provided by a hydraulic loading system? Achieve Maximum Densification

- Why KBr is used in IR spectrophotometry? A Key to Transparent Sample Analysis

- How do you prepare pressed pellets for XRF? A Step-by-Step Guide to Reliable Sample Analysis

- What is the thickness of filter press cloth? Selecting the Right Cloth for Your Filtration Goals

- How much pressure can a hydraulic press? Understand the Difference Between Pressure and Force

- Why is a laboratory hydraulic press utilized for layered pre-pressing? Mastering Ti2AlN/TiN Material Fabrication

- What is the function of laboratory hydraulic presses and precision molds? Ensure HEA-Ceramic Composite Integrity

- Why we use KBr pellets in IR? Unlock Clear Sample Analysis with Infrared-Transparent Matrix