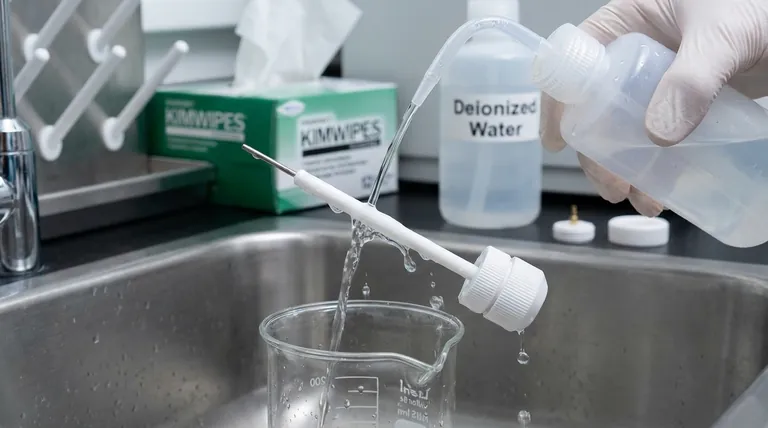

For routine maintenance, an electrode holder should be periodically cleaned by rinsing it with deionized water and then thoroughly drying it. This simple process removes surface dirt, electrolyte residue, and other contaminants without damaging the holder's components.

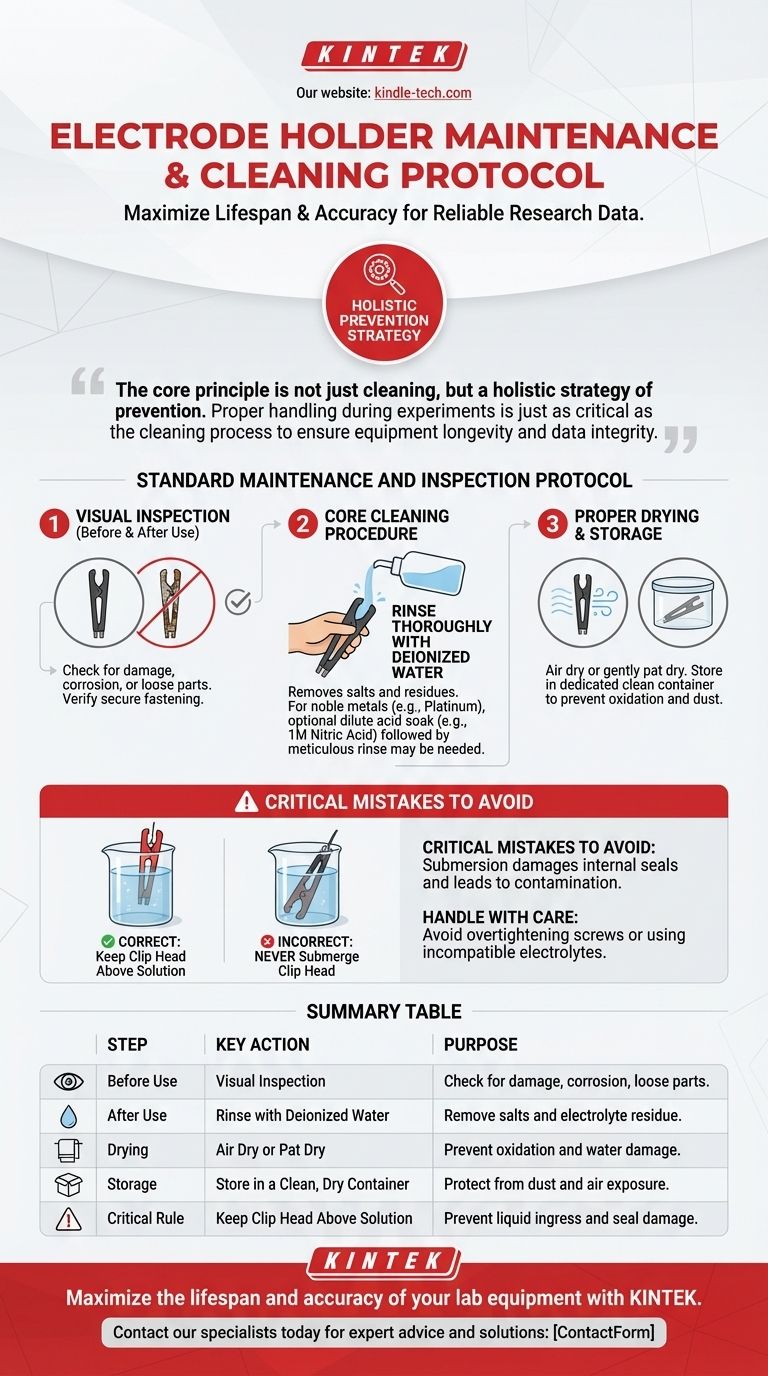

The core principle of electrode holder maintenance is not just cleaning, but a holistic strategy of prevention. Proper handling during experiments is just as critical as the cleaning process itself to ensure both the longevity of the equipment and the integrity of your experimental data.

The Standard Maintenance and Inspection Protocol

Effective maintenance begins with understanding the physical components of your holder and what to look for before and after each use. This routine prevents minor issues from becoming major failures.

Step 1: Visual Inspection Before and After Use

Before cleaning, always perform a quick visual check. Look for any signs of physical damage, corrosion, or wear on the electrode surfaces and the holder itself.

Confirm that fastening components, like screws, are secure and that the clip head opens and closes correctly. Loose or damaged parts should be repaired or replaced immediately.

Step 2: The Core Cleaning Procedure

The most reliable method for routine cleaning is straightforward. Rinse the electrode holder thoroughly with deionized water. This is sufficient to remove most salts and surface residues from your electrolyte.

For noble metal electrodes like platinum that may have more stubborn contaminants, a more intensive cleaning may be needed. This can involve soaking in a dilute acid (e.g., 1M nitric acid) followed by a meticulous rinse with deionized water.

Step 3: Proper Drying and Storage

After rinsing, the holder must be dried completely to prevent oxidation or water damage. Gently pat it dry or allow it to air dry in a clean environment.

When not in use for extended periods, store the dry electrode and holder in a dedicated container. This protects it from dust and, crucially, minimizes exposure to air, which can oxidize certain metal electrodes.

Critical Mistakes to Avoid During Operation

How you use the holder is the most significant factor in its lifespan. Avoiding common operational errors is the best form of maintenance.

The Cardinal Rule: Never Submerge the Clip Head

Only the test sample sheet should be immersed in the electrolyte solution. The clip head of the holder must remain above the liquid level.

The solder points within the clip head are often sealed with an adhesive. Prolonged immersion can damage this seal, leading to solution contamination or liquid seeping into the electrode holder, causing irreparable damage.

Preventing Physical and Chemical Damage

Handle electrodes with care, as many types, such as platinum sheets, are fragile. When securing your sample, tighten the screw just enough to hold it firmly without scratching or deforming the surface.

Always select an electrolyte that is non-corrosive and non-reactive with both your test sample and the holder's conductive materials. An incompatible electrolyte is a primary cause of premature equipment failure.

Applying This to Your Workflow

Your maintenance strategy should adapt to your specific needs and frequency of use. A consistent routine is the key to reliable and repeatable results.

- Before every experiment: Perform a quick visual inspection of the holder and electrode for any damage, corrosion, or loose parts.

- After routine use: Follow the standard protocol of rinsing with deionized water and allowing it to dry completely.

- If you suspect contamination or poor performance: Use a more intensive method appropriate for your electrode type, such as acid washing for platinum or polishing for gold.

- For long-term storage: Ensure the holder is completely dry and kept in a clean, dedicated container to prevent oxidation and contamination.

Adhering to a disciplined maintenance protocol is the foundation of trustworthy electrochemical measurements.

Summary Table:

| Maintenance Step | Key Action | Purpose |

|---|---|---|

| Before Use | Visual Inspection | Check for damage, corrosion, or loose parts. |

| After Use | Rinse with Deionized Water | Remove salts and electrolyte residue. |

| Drying | Air Dry or Pat Dry | Prevent oxidation and water damage. |

| Storage | Store in a Clean, Dry Container | Protect from dust and air exposure. |

| Critical Rule | Keep Clip Head Above Solution | Prevent liquid ingress and seal damage. |

Maximize the lifespan and accuracy of your lab equipment with KINTEK. Proper maintenance is key to reliable data. Whether you need durable electrode holders, high-purity electrodes, or expert advice on electrochemical cell care, KINTEK is your partner for laboratory excellence. Contact our specialists today to find the perfect solutions for your research needs and ensure your experiments run flawlessly.

Visual Guide

Related Products

- Sample Support Body for Electrochemical Tests

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Copper Sulfate Reference Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- How does a single-granule electrochemical fixture assist in analyzing the performance of individual granules within a fixed bed? Unlock Precise Particle Insights

- What are the proper procedures for post-treatment and storage of an electrode holder after an experiment? Ensure Accuracy and Longevity

- What are the factors affecting sample size requirements? Master the Trade-Offs for Credible Research

- How should the PTFE electrode stand be adjusted to fit the electrolytic cell? Ensure Maximum Stability for Your Experiments

- What are the steps for post-experiment procedures after using the cell with a conventional aqueous solution? Ensure Accuracy and Reproducibility