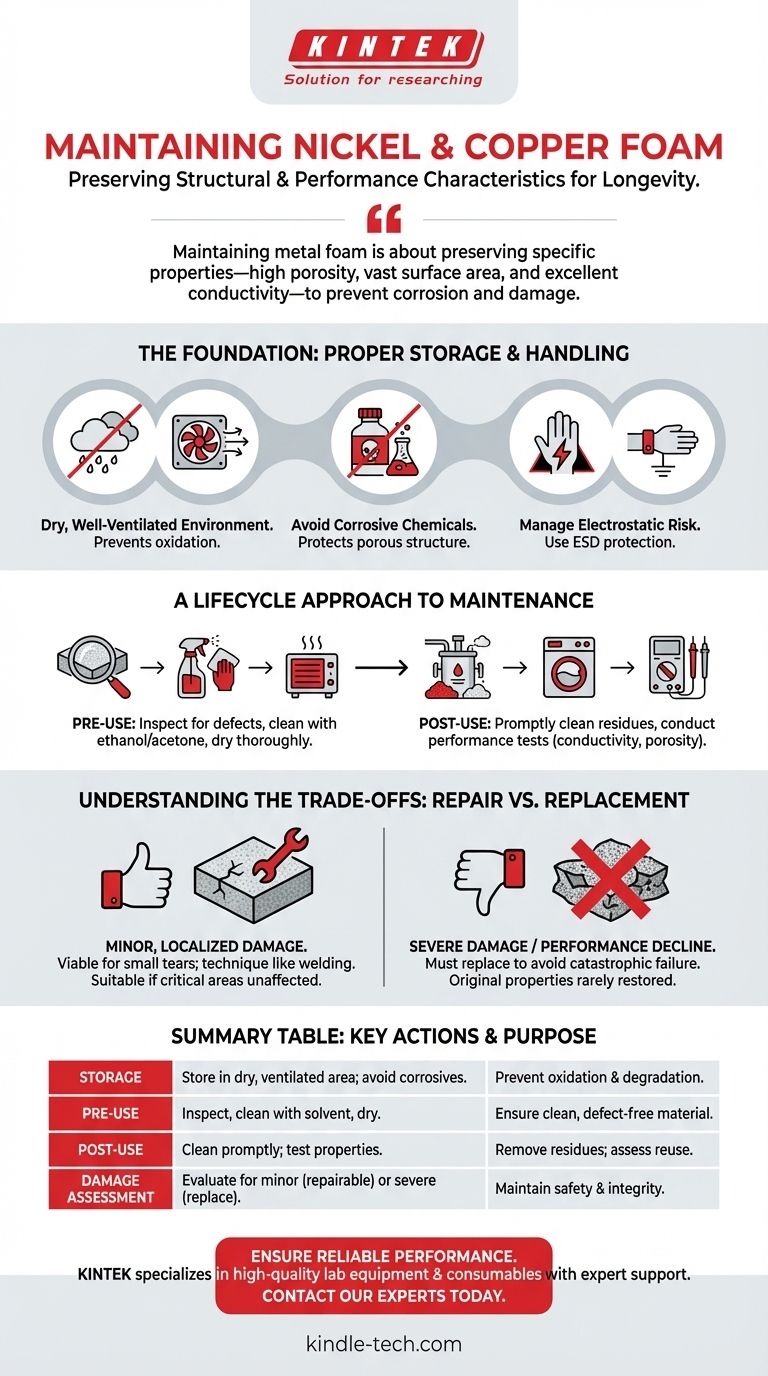

Proper maintenance of nickel and copper foam is essential for preserving their unique structural and performance characteristics. The core of this process involves storing the material in a dry, well-ventilated environment away from corrosive chemicals, performing thorough pre-use and post-use cleaning with appropriate solvents, and conducting regular inspections for physical damage or performance degradation.

Maintaining metal foam is not merely about cleaning; it is about preserving the specific properties—high porosity, vast surface area, and excellent conductivity—that make it valuable. The ultimate goal is to prevent chemical corrosion and physical damage that compromises these attributes, ensuring consistent performance and longevity in your application.

The Foundation: Proper Storage and Handling

The first line of defense in protecting your investment is controlling the material's environment when not in use. Metal foams are sensitive to both chemical and physical influences.

Creating a Safe Storage Environment

Nickel and copper foams must be stored in a dry, well-ventilated location. Moisture is a primary catalyst for oxidation and degradation, which can quickly compromise the material's performance.

Preventing Chemical Corrosion

It is critical to avoid all contact with corrosive substances. Store the foam away from strong acids and strong alkalis, as these chemicals can aggressively attack the metal matrix and destroy its intricate porous structure.

Managing Electrostatic Risk

Due to their excellent electrical conductivity, both nickel and copper foam can pose a risk in electrostatically sensitive environments. When handling the foam near sensitive electronics, always use proper electrostatic discharge (ESD) protection to prevent damage to the foam or surrounding equipment.

A Lifecycle Approach to Maintenance

A systematic maintenance protocol that covers every stage of use—from initial preparation to post-application assessment—will yield the most reliable results.

Pre-Use Preparation

Before every use, visually inspect the foam's surface for any defects, deformation, or impurities. This ensures you are starting with a material that meets quality standards.

Following inspection, clean the foam with a suitable solvent like ethanol or acetone to remove surface contaminants such as oil and dust. Ensure the foam is dried thoroughly before use to prevent any interference from residual solvent.

Post-Use Cleaning and Assessment

After an application, such as a catalytic reaction, you must promptly clean the foam. This involves removing any reactant residues, byproducts, or carbon deposits that adhere to the surface.

Once clean, conduct performance tests to quantify any changes. Measuring properties like electrical conductivity and porosity provides an objective assessment of the material's condition and helps you decide if it is suitable for reuse.

Understanding the Trade-offs: Repair vs. Replacement

Not all damage is equal. Knowing when to repair and when to replace is key to maintaining both safety and performance integrity.

When to Attempt a Repair

For minor, localized damage, repair may be a viable option. Techniques like welding can sometimes fix small tears or breaks without significantly impacting the overall structure.

This approach is only suitable if the damage is minimal and does not affect the critical performance areas of the foam.

The Criticality of Replacement

If the foam exhibits severe physical damage or a significant, irreversible decline in performance, it must be replaced. Continuing to use a compromised material risks catastrophic failure and, more importantly, unreliable results in your experiment or product.

Attempting to repair major damage is often a false economy, as the material's original, specified properties can rarely be restored.

Tailoring Your Maintenance to Your Application

The intensity of your maintenance protocol should align with the sensitivity of your work. The right approach ensures the material remains fit for its specific purpose.

- If your primary focus is high-precision applications (e.g., catalysis, electrodes): Rigorous post-use cleaning and performance testing are non-negotiable to ensure data integrity and repeatability.

- If your primary focus is thermal or structural management (e.g., heat sinks, lightweight cores): Prioritize regular visual inspection for physical damage and ensure clean surfaces for optimal thermal or mechanical performance.

- If your primary focus is long-term deployment: Establishing a strict, documented storage and handling protocol is the most critical factor in maximizing the material's operational lifespan.

A disciplined maintenance routine is your best defense against premature material failure and inconsistent outcomes.

Summary Table:

| Maintenance Stage | Key Action | Purpose |

|---|---|---|

| Storage | Store in dry, ventilated area; avoid corrosive chemicals. | Prevent oxidation and chemical degradation. |

| Pre-Use | Inspect for damage; clean with ethanol/acetone; dry thoroughly. | Ensure material is clean and defect-free. |

| Post-Use | Clean promptly; test conductivity/porosity. | Remove residues; assess performance for reuse. |

| Damage Assessment | Evaluate for minor (repairable) or severe (replace) damage. | Maintain safety and performance integrity. |

Ensure your lab's metal foams perform reliably. Proper maintenance is key to preserving the high porosity and conductivity critical for applications in catalysis, filtration, and energy storage. KINTEK specializes in providing high-quality lab equipment and consumables, including nickel and copper foams, backed by expert technical support. Let our team help you select the right materials and establish effective maintenance protocols for consistent, repeatable results. Contact our experts today to discuss your specific laboratory needs.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

People Also Ask

- How is deposition time calculated? Mastering the Clock for Strategic Legal Advantage

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is gold sputtered? A Guide to High-Purity Vacuum Coating for Electronics & SEM

- What is sputter coating used for? Achieve Superior Thin Films for Electronics, Optics, and Tools

- What are sputtering systems used for? A Guide to Advanced Thin-Film Deposition