Deposition time is calculated based on a simple, yet critical, principle: it is the time a legal party spends actively asking questions of a witness. This "on the clock" time is charged to the questioning side only. It strategically excludes breaks, arguments between lawyers, and the time the witness spends formulating and delivering their answers.

The core concept to grasp is that the deposition clock is not a stopwatch for the entire event. Instead, it measures only the time used for oral examination, starting when a question begins and stopping when it ends.

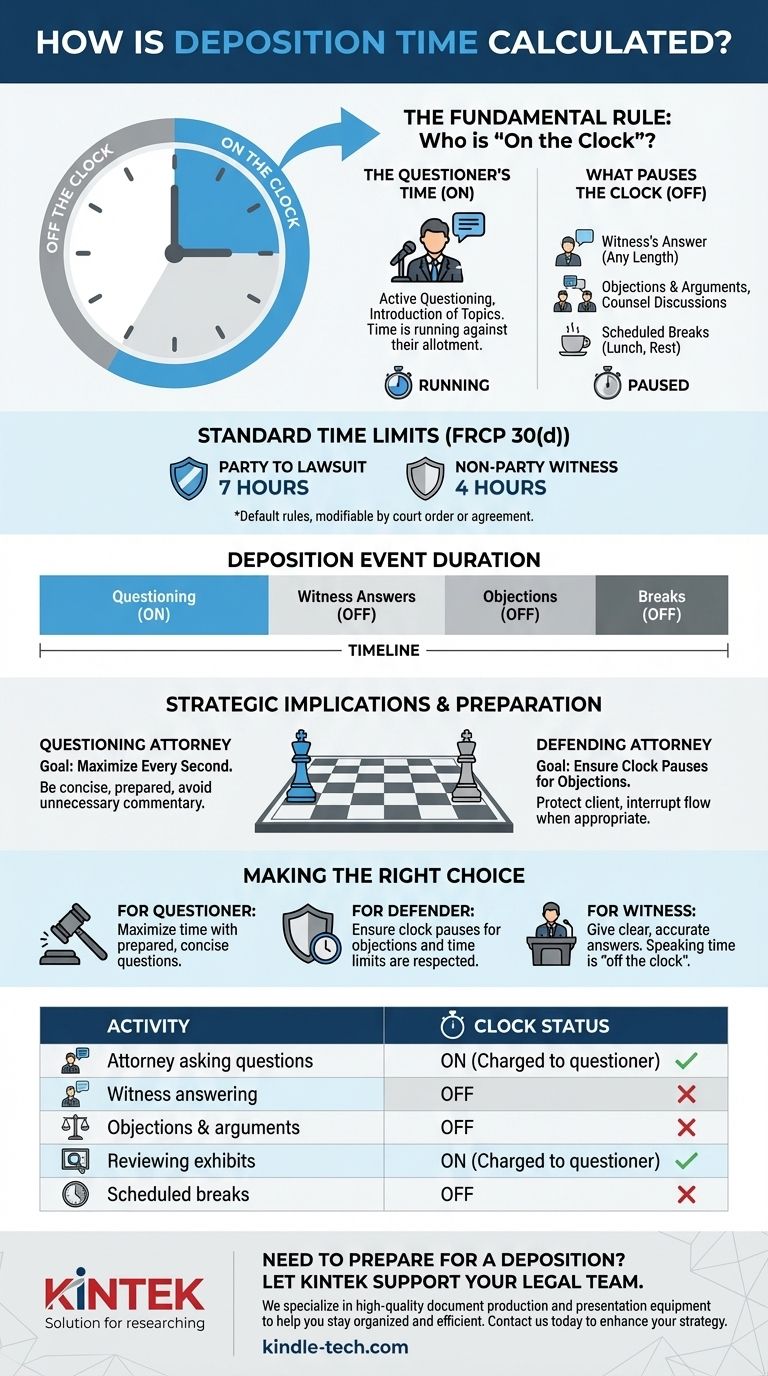

The Fundamental Rule: Who is "On the Clock"?

Understanding how the deposition clock works is less about complex math and more about knowing which activities count against the legally mandated time limits.

The Questioner's Time

The clock belongs exclusively to the party conducting the questioning. When their lawyer is speaking to ask a question or introduce a topic for questioning, the time is running against their side's allotment.

What Pauses the Clock

Any activity that is not direct questioning is considered "off the clock." This is the most misunderstood aspect of the calculation.

Common "off the clock" events include:

- The witness's answer, no matter how long it is.

- Objections and arguments made by the opposing counsel.

- Discussions and arguments between the lawyers.

- Scheduled breaks for lunch or rest.

Standard Time Limits

Under the Federal Rules of Civil Procedure, there are default time limits. Rule 30(d) establishes a seven-hour limit for questioning a party to the lawsuit and a four-hour limit for questioning a nonparty.

These are default rules and can be modified by a court order or by an agreement (a stipulation) between the legal parties.

Understanding the Strategic Implications

The rules for calculating deposition time create a strategic landscape that all participants must navigate carefully. It's not just about compliance; it's about control.

Why the Clock Favors the Prepared

An unprepared questioning attorney can easily waste their allotted time with unfocused or repetitive questions. A well-prepared attorney uses every minute to build their case.

Conversely, a defending attorney's primary job is to protect their client and the integrity of the record, using objections to pause the clock and disrupt the questioner's flow when legally appropriate.

The Nuance of Exhibits

Time spent directing a witness to review a document or exhibit is generally considered "on the clock" for the questioner. This is because the review is a necessary predicate to the question itself.

The Risk of Running Out of Time

The time limit is a hard stop. If the questioning party runs out of time, they lose their opportunity to ask further questions, which could be detrimental to their case. This makes efficient time management a critical lawyering skill.

Making the Right Choice for Your Goal

How you approach the time limit depends entirely on your role in the proceeding.

- If you are the questioning attorney: Your goal is to maximize every second by asking concise, prepared questions and avoiding unnecessary commentary that keeps you on the clock.

- If you are the defending attorney: Your objective is to ensure the clock is paused for your objections and that the questioning party does not exceed their allotted time without a formal agreement.

- If you are the witness (deponent): You should focus on giving clear and accurate answers, understanding that the time you spend speaking does not count against the questioner's limit.

Ultimately, mastering the deposition clock is about understanding that only the act of asking questions counts against the limit.

Summary Table:

| Activity | Clock Status (On/Off) |

|---|---|

| Attorney asking questions | On (Charged to questioner) |

| Witness answering | Off |

| Objections & arguments between counsel | Off |

| Reviewing exhibits with witness | On (Charged to questioner) |

| Scheduled breaks (lunch, rest) | Off |

Standard Default Time Limits (FRCP 30(d))

| Deponent Type | Time Limit |

|---|---|

| Party to the lawsuit | 7 hours |

| Non-party witness | 4 hours |

Need to Prepare for a Deposition? Let KINTEK Support Your Legal Team.

A successful deposition requires precise preparation and reliable tools. KINTEK specializes in providing high-quality document production and presentation equipment for legal professionals. From exhibit binders to presentation displays, our solutions help your team stay organized and efficient, ensuring you make the most of every minute on the deposition clock.

We help you:

- Organize and present exhibits clearly and professionally.

- Maintain a seamless workflow during critical legal proceedings.

- Project confidence and preparedness to all parties.

Contact KINTEK today to discuss how our products can enhance your deposition strategy and support your case preparation.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

People Also Ask

- What is the unit of measurement for melting point? Celsius, Kelvin, or Fahrenheit?

- What are the liquid products of pyrolysis? The Ultimate Guide to Bio-Oil Production

- What are the benefits of converting plastic to fuel? Turn Waste into Energy & Reduce Landfill

- What is difference between FTIR and IR? The Revolutionary Leap in Modern Spectroscopy

- What are the disadvantages of wiped film molecular still? High Cost, Complexity & Separation Limits

- What is the primary function of laboratory ovens in biomass moisture determination? Ensure Accurate Energy Calibration

- What are the elements of bio-oil? Unlocking the Chemistry of Renewable Fuel

- What is the function of a magnetic stirrer in MgAl-LDH coprecipitation? Ensure Uniformity and Precision