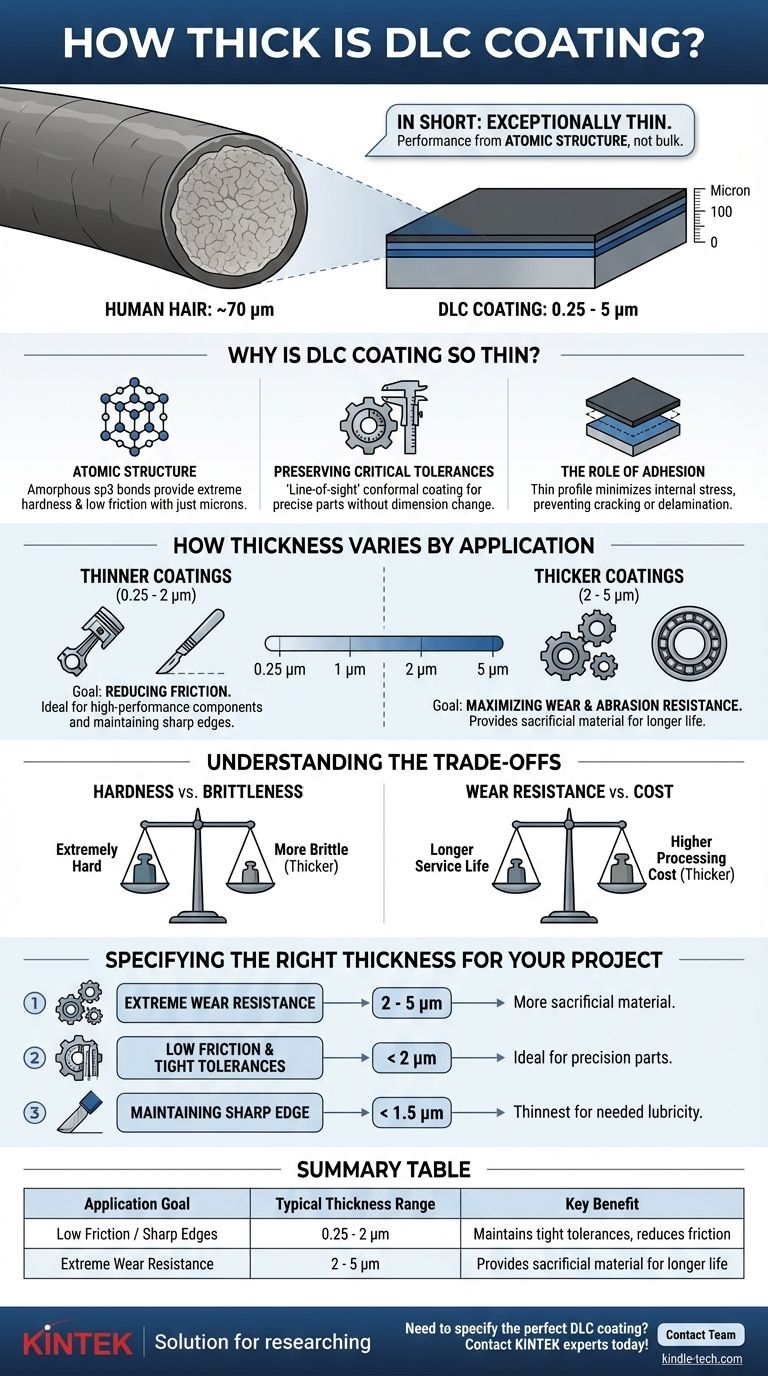

In short, a typical DLC coating is exceptionally thin. Its thickness is measured in microns and generally ranges from 0.25 to 5 microns (µm). For perspective, a human hair is about 70 microns thick, making even the thickest DLC coating over 10 times thinner.

The critical takeaway is that DLC's performance comes from its unique atomic structure, not its bulk. The coating's thickness is a carefully engineered parameter tailored to the specific demands of the application, balancing wear resistance against internal stress and component tolerances.

Why is DLC Coating So Thin?

The effectiveness of Diamond-Like Carbon (DLC) coatings is not a matter of simply adding a thick, hard shell. The value lies in its microscopic properties and how it bonds to a surface.

The Power of Atomic Structure

The defining characteristic of DLC is its amorphous carbon structure, rich in diamond-like sp3 bonds. This atomic arrangement provides extreme hardness and a naturally low coefficient of friction. A layer just a few microns thick is all that is needed to impart these properties to the surface of a component.

Preserving Critical Tolerances

Because DLC is so thin, it's considered a "line-of-sight" conformal coating. This means it can be applied to highly precise components—like engine pistons, fuel injectors, or surgical tools—without materially changing their critical dimensions or requiring subsequent machining.

The Role of Adhesion

A coating is only as good as its bond to the substrate. As a DLC layer gets thicker, internal stresses can build within the coating. If these stresses become too high, the coating can crack or delaminate from the surface, leading to failure. Maintaining a thin profile is key to ensuring its durability and adhesion.

How Thickness Varies by Application

The ideal thickness for a DLC coating is not a single number but a target chosen based on the primary problem you are trying to solve.

Thinner Coatings (0.25 - 2 µm)

For applications where the primary goal is reducing friction, a thinner coating is often optimal. This is common in high-performance automotive components or on cutting tools that require an extremely sharp edge, where any added thickness could dull the blade.

Thicker Coatings (2 - 5 µm)

When the primary goal is maximizing wear and abrasion resistance, a thicker coating is generally specified. This provides more sacrificial material to withstand abrasive contact over a longer period, which is ideal for components like gears, bearings, and industrial tooling.

Understanding the Trade-offs

Choosing the thickness of a DLC coating involves balancing competing factors. Understanding these trade-offs is essential for successful application.

Hardness vs. Brittleness

While DLC is extremely hard, increasing its thickness can also increase its internal stress, making it more brittle. A very thick coating on a part that flexes or experiences high impact can be more prone to cracking than a thinner, more compliant layer.

Wear Resistance vs. Cost

Applying a thicker coating requires a longer deposition time in the PVD (Physical Vapor Deposition) chamber. This directly translates to a higher processing cost. Therefore, one must balance the required service life against the budget for the coating process.

Specifying the Right Thickness for Your Project

The correct DLC thickness is a deliberate engineering choice driven entirely by the component's intended function and environment.

- If your primary focus is extreme wear resistance for industrial parts: A thicker coating in the 2-5 micron range is typically specified to provide more sacrificial material.

- If your primary focus is low friction and preserving tight tolerances for precision components: A thinner coating, often 2 microns or less, is the ideal choice.

- If your primary focus is maintaining a sharp edge on cutting tools: The thinnest possible coating that provides the needed lubricity, often under 1.5 microns, is best.

Ultimately, selecting the right thickness transforms a component from simply being coated to being truly engineered for performance.

Summary Table:

| Application Goal | Typical Thickness Range | Key Benefit |

|---|---|---|

| Low Friction / Sharp Edges | 0.25 - 2 µm | Maintains tight tolerances, reduces friction |

| Extreme Wear Resistance | 2 - 5 µm | Provides sacrificial material for longer life |

Need to specify the perfect DLC coating thickness for your components? KINTEK specializes in precision lab equipment and consumables for surface engineering. Our experts can help you balance wear resistance, friction, and cost to engineer your components for peak performance. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is the frequency of PECVD? Mastering Plasma Control for Superior Thin Films

- Why can plasma-enhanced cvd PECVD operate at relatively lower temperature as compared to lpcvd? Unlock Low-Temp Thin Film Deposition

- What are the technical advantages of PECVD vs. CVD for CF2 films? Master Precision Nano-Engineering

- How strong is DLC coating? Discover the Ultimate Shield for Wear and Friction

- What is plasma assisted physical vapor deposition? Enhance Your Coating Performance with Advanced PA-PVD

- Can you DLC coat plastic? Achieve High-Performance Scratch Resistance for Your Polymer Parts

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films