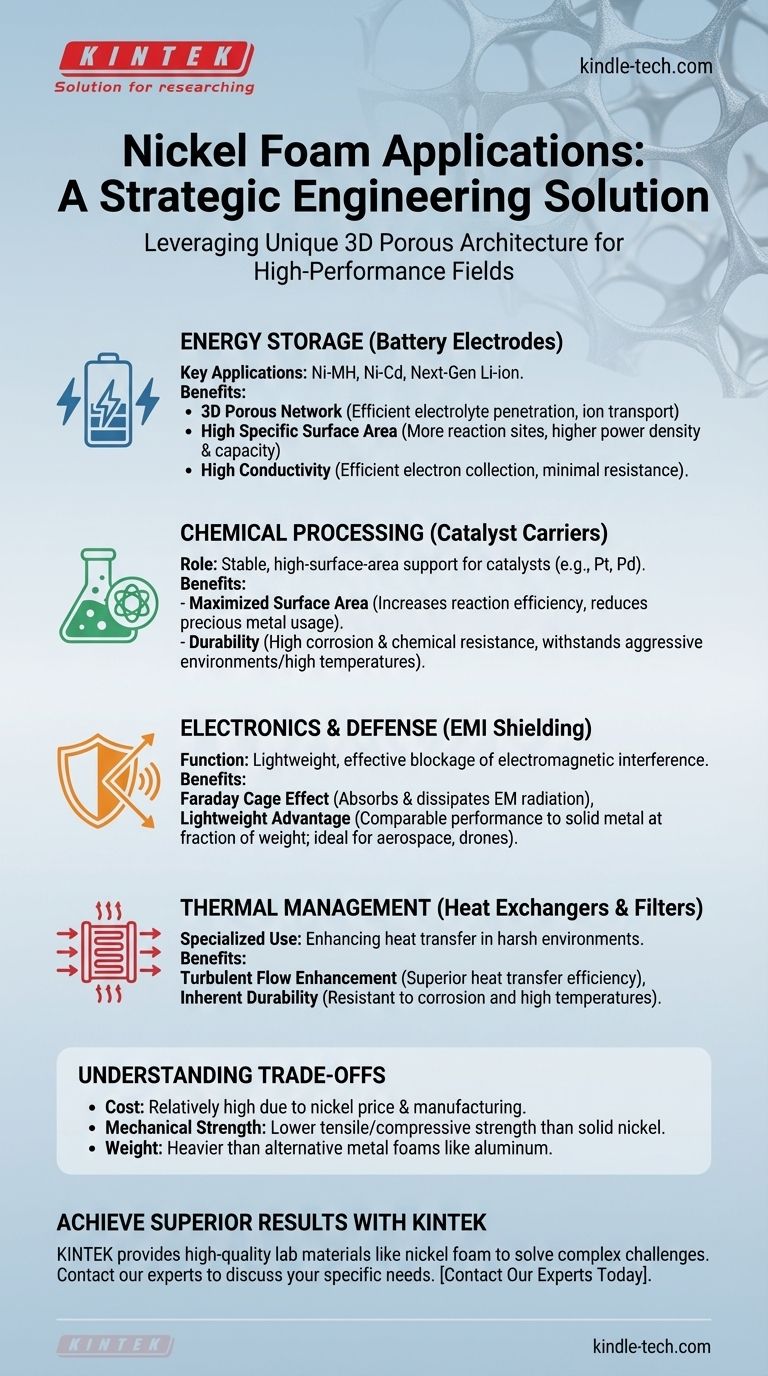

In short, nickel foam's unique structure makes it a critical material in several advanced fields. It is most widely used for high-performance battery electrodes, as a carrier for chemical catalysts, in electromagnetic shielding applications, and for specialized heat exchangers and filters.

The true value of nickel foam lies not in the nickel itself, but in its three-dimensional, porous architecture. This "metal sponge" creates a combination of immense surface area, low weight, and high conductivity that solid metal cannot match, making it a solution for complex engineering problems.

Energy Storage: High-Performance Battery Electrodes

Nickel foam serves as a current collector and electrode substrate, particularly in Nickel-Metal Hydride (Ni-MH) and Nickel-Cadmium (Ni-Cd) batteries, and is being explored for next-generation lithium-ion batteries.

Why it Works for Batteries

The foam's three-dimensional porous network allows the battery's electrolyte to fully penetrate the electrode, ensuring efficient ion transport.

Its high specific surface area provides more reaction sites for the active material. This directly translates to higher power density (faster charging/discharging) and greater overall capacity.

Finally, the inherent electrical conductivity of the nickel skeleton ensures efficient collection and transfer of electrons with minimal resistance.

Chemical Processing: Catalyst Carriers

In industrial chemistry, catalysts are often expensive precious metals. Nickel foam acts as a stable, high-surface-area support structure to hold these catalytic materials.

The Role of Surface Area

The foam’s vast internal surface area allows a very small amount of an active catalyst (like platinum or palladium) to be distributed widely. This maximizes the catalyst's exposure to reactants, dramatically increasing reaction efficiency and reducing costs.

Durability in Harsh Environments

Nickel's natural corrosion resistance and high chemical stability make the foam an ideal support structure inside chemical reactors. It can withstand aggressive chemicals and high temperatures without degrading, ensuring a long operational life.

Electronics and Defense: Electromagnetic Shielding

Electromagnetic interference (EMI) can disrupt or disable sensitive electronic components. Nickel foam provides a lightweight and effective solution for blocking this unwanted radiation.

How it Blocks Interference

The foam's interconnected conductive network functions like a complex Faraday cage. When electromagnetic waves hit the foam, they are absorbed and dissipated throughout the metallic structure, effectively shielding the components behind it.

The Lightweight Advantage

Compared to solid metal plates, nickel foam offers comparable shielding performance at a fraction of the weight. This is a critical advantage in weight-sensitive applications like aerospace, drones, and portable medical devices.

Understanding the Trade-offs

While highly effective, nickel foam is not a universal solution. Its selection requires balancing its benefits against its limitations.

Primary Consideration: Cost

Nickel is a relatively expensive metal, and the manufacturing process for creating high-purity foam adds to the cost. For applications where aluminum or copper foam would suffice, nickel is often the more expensive option.

Mechanical Strength Limitations

By design, a foam is mostly empty space. While rigid, it does not possess the tensile or compressive strength of a solid nickel block. It can be crushed under high mechanical loads, making it unsuitable for primary structural roles.

Weight vs. Other Foams

Although much lighter than solid nickel, it is denser and heavier than other metal foams, such as aluminum foam. In applications where weight is the absolute single most important factor and conductivity or corrosion resistance is secondary, aluminum may be preferred.

Making the Right Choice for Your Application

Your specific goal will determine if nickel foam is the correct material choice.

- If your primary focus is energy density and power delivery: Nickel foam's combination of high surface area, porosity, and conductivity is nearly unmatched for battery electrodes.

- If your primary focus is maximizing catalytic reaction efficiency: Its massive surface area and chemical stability make it an ideal carrier for reducing the amount of precious catalyst needed.

- If your primary focus is lightweight EMI shielding: Its conductive network provides excellent shielding effectiveness without the weight penalty of solid metal plates.

- If your primary focus is thermal transfer in a high-temperature or corrosive environment: The foam's turbulent flow enhancement and nickel's inherent durability make it a superior choice for specialized heat exchangers.

By understanding these core properties, you can leverage nickel foam not just as a material, but as a strategic engineering solution.

Summary Table:

| Field | Primary Application | Key Benefit of Nickel Foam |

|---|---|---|

| Energy Storage | Battery Electrodes | High surface area & conductivity for power density |

| Chemical Processing | Catalyst Carrier | Maximizes catalyst efficiency & resists corrosion |

| Electronics/Defense | EMI Shielding | Lightweight, effective radiation blocking |

| Thermal Management | Heat Exchangers & Filters | Enhances heat transfer in harsh environments |

Need a High-Performance Material Solution for Your Lab?

Nickel foam's unique properties can solve complex challenges in energy storage, catalysis, and shielding. KINTEK specializes in providing high-quality lab equipment and materials, including advanced substrates like nickel foam, to enhance your research and development.

Let us help you achieve superior results. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

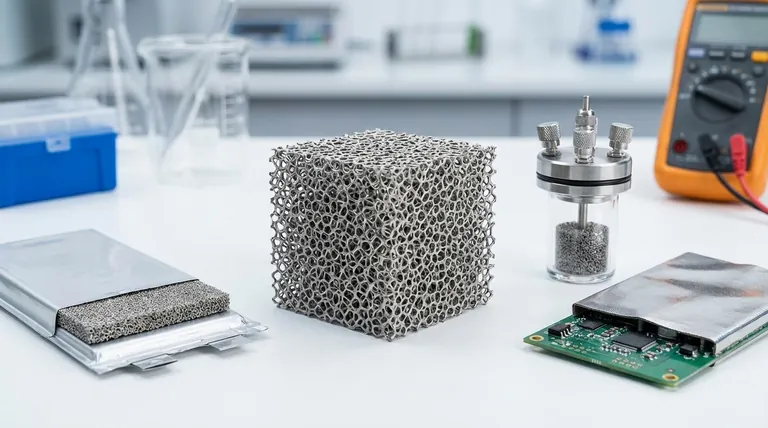

Visual Guide

Related Products

- MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Float Soda-Lime Optical Glass for Laboratory Use

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What role does the dielectric window play in MW-SWP CVD equipment? Ensuring Stable Plasma Generation with Quartz

- Why is a PTFE plate selected as the casting substrate for solid polymer electrolytes? Ensure Damage-Free Release

- What is the substrate for CVD process? Choosing the Right Foundation for Your Thin Film

- What is the best substrate for graphene? It depends on your application's specific needs.

- What is the primary function of a sapphire glass window? Optimizing High-Throughput IR Thermography Reactors