Yes, brazing is a fundamental and widely used metal joining process. It joins two or more base metal components by heating them and using a molten filler material to form a strong bond. Critically, the process melts the filler material but does not melt the base metals being joined.

Brazing is a distinct joining method that sits between soldering and welding. Its defining characteristic is the ability to create strong, permanent joints without melting the base materials, which preserves their integrity and allows for high-precision assemblies.

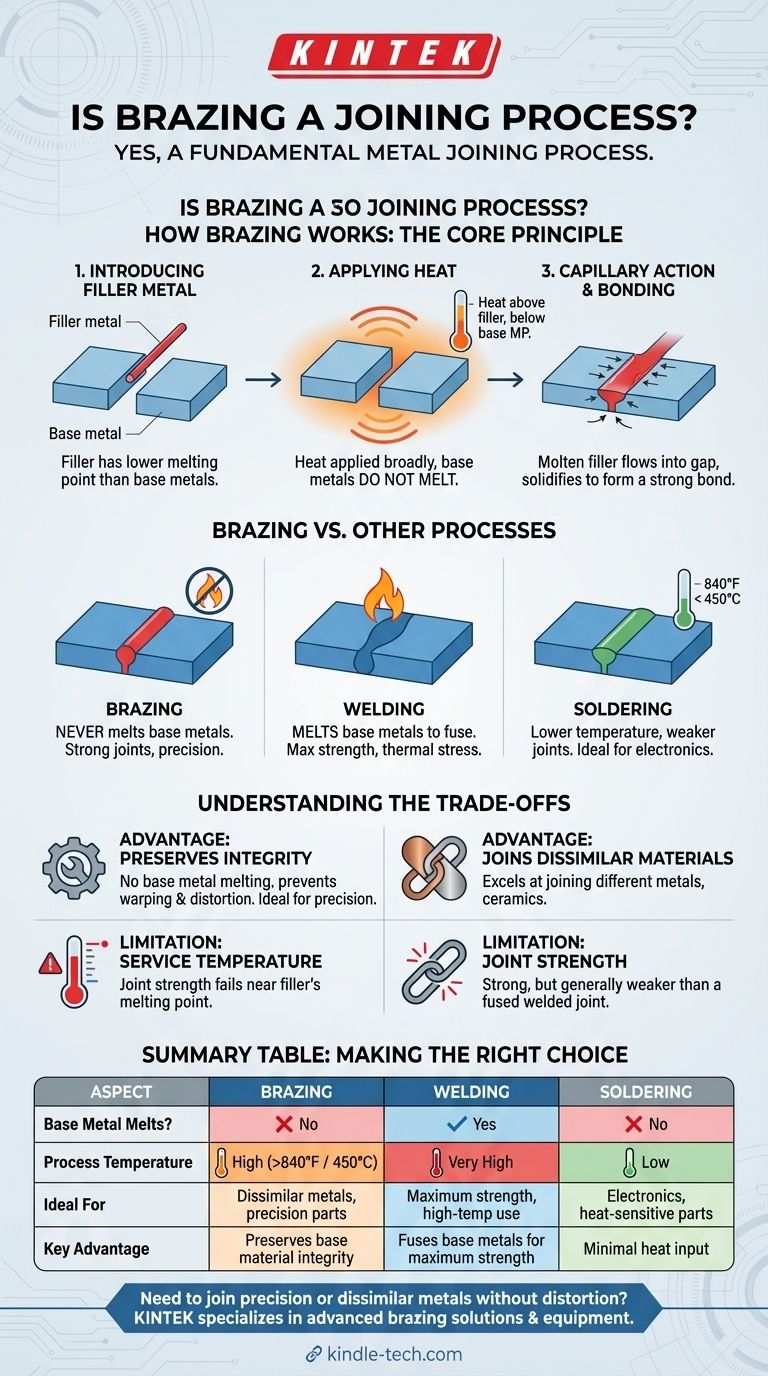

How Brazing Works: The Core Principle

Brazing is a thermal process governed by a few key elements that work together to create a robust metallurgical bond between components.

Introducing the Filler Metal

The process relies on a filler metal that has a lower melting point than the base materials being joined. This filler is designed to flow easily when molten and bond chemically with the base metals.

The Role of Heat

Heat is applied broadly to the base materials around the joint area. The goal is to bring the components to a temperature that is above the melting point of the filler metal but below the melting point of the base materials.

Capillary Action and Bonding

Once the filler metal is introduced to the heated joint, it melts instantly. This liquid metal is drawn into the narrow gap between the closely-fitted base components through a process called capillary action. As it cools and solidifies, it forms a strong, permanent metallurgical bond.

Brazing vs. Other Joining Processes

Understanding how brazing differs from welding and soldering is key to appreciating its specific applications and advantages.

Brazing vs. Welding

The fundamental difference is that welding melts the base metals to fuse them together, often with or without a filler. Brazing, by contrast, never melts the base metals. This distinction leads to less thermal stress, reduced risk of warping, and cleaner joints requiring less finishing.

Brazing vs. Soldering

Brazing and soldering are conceptually similar, as both use a molten filler to join non-molten base metals. The primary difference is temperature. Brazing occurs at much higher temperatures (conventionally above 840°F or 450°C), resulting in a significantly stronger and more durable joint than soldering.

Understanding the Trade-offs

While powerful, brazing is not the right solution for every problem. Understanding its limitations is critical for proper application.

Key Advantage: Preserving Material Integrity

By avoiding the melting of base metals, brazing is ideal for joining precision components. It prevents the distortion, warping, and changes to material properties that can occur during the high heat of welding.

Key Advantage: Joining Dissimilar Materials

Since the base metals are not being fused together, brazing excels at joining dissimilar materials, such as copper to steel or ceramic to metal, which can be very difficult or impossible to weld.

The Limitation: Service Temperature

A brazed joint's strength is dependent on the solidified filler material. Therefore, the joint cannot be used in an environment where the temperature would approach the filler's melting point, as this would cause it to weaken and fail.

The Limitation: Joint Strength

While very strong, a brazed joint is generally not as strong as a properly executed welded joint. The overall strength is determined by the filler material, which is typically weaker than the base metals being joined.

Making the Right Choice for Your Goal

Selecting the correct joining process depends entirely on the requirements for strength, precision, and operating conditions.

- If your primary focus is maximum joint strength and high-temperature performance: Welding is often the superior choice because it fuses the base metals directly.

- If your primary focus is precision, joining dissimilar metals, or minimizing thermal distortion: Brazing is the ideal process, as it joins components without altering the base materials.

- If your primary focus is joining heat-sensitive components at low temperatures, especially in electronics: Soldering is the correct method due to its much lower heat requirements.

Understanding these core distinctions empowers you to select the most effective joining process for the specific demands of your project.

Summary Table:

| Aspect | Brazing | Welding | Soldering |

|---|---|---|---|

| Base Metal Melts? | No | Yes | No |

| Process Temperature | High (>840°F / 450°C) | Very High | Low |

| Ideal For | Dissimilar metals, precision parts | Maximum strength, high-temp use | Electronics, heat-sensitive parts |

| Key Advantage | Preserves base material integrity | Fuses base metals for maximum strength | Minimal heat input |

Need to join precision or dissimilar metals without distortion? KINTEK specializes in advanced brazing solutions and laboratory equipment for creating strong, reliable joints. Our expertise ensures your assemblies meet the highest standards of quality and performance. Contact our brazing specialists today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing