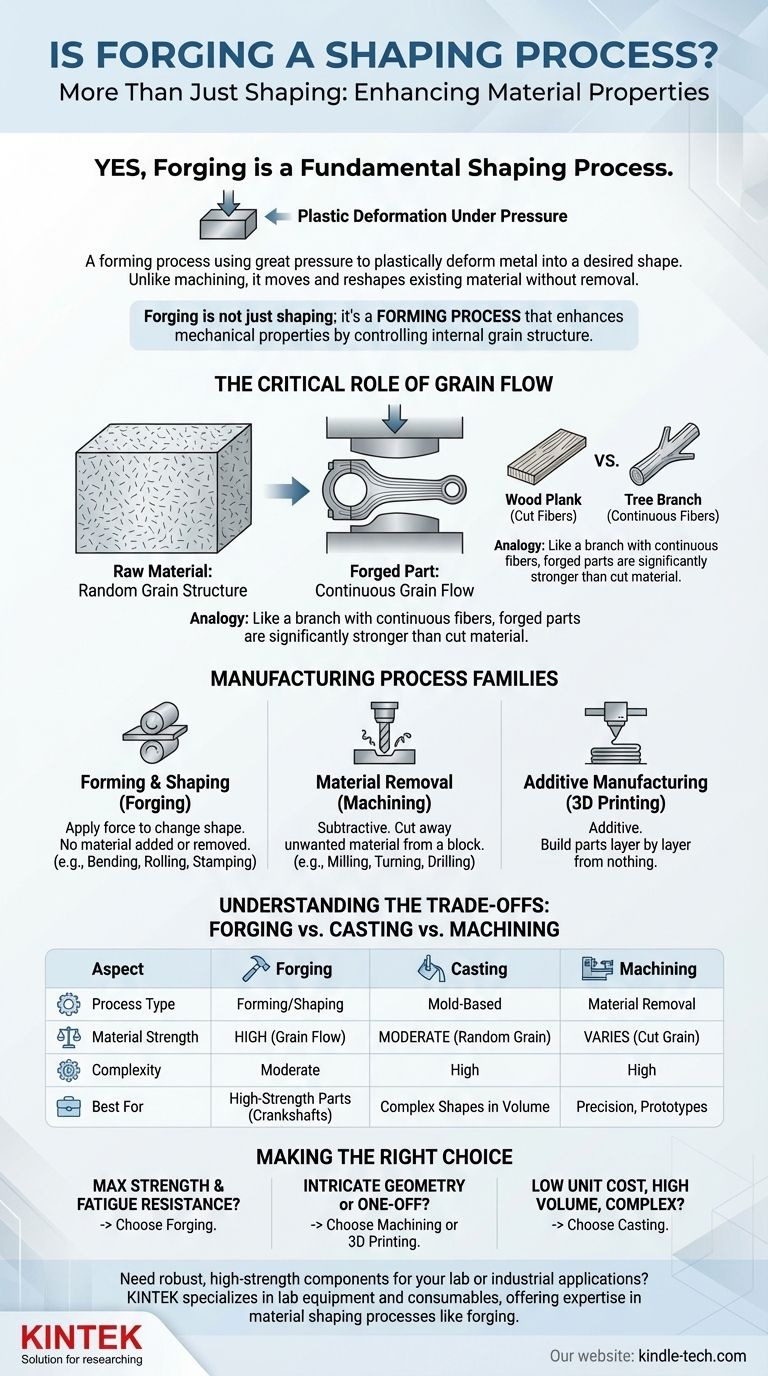

Yes, forging is a fundamental shaping process used in manufacturing. It is a type of forming process where a piece of metal is plastically deformed under great pressure to produce a desired shape. Unlike machining, which cuts material away, forging moves and reshapes the existing material.

Forging is not just a shaping process; it is a forming process that enhances the material's mechanical properties. By controlling the metal's internal grain structure, forging produces parts that are significantly stronger and more durable than those made by casting or machining alone.

What Defines a Manufacturing Process?

To understand where forging fits, it's helpful to categorize the primary ways we shape materials. Manufacturing processes generally fall into three main families.

Forming and Shaping

These processes, including forging, apply force to a solid material to change its shape without adding or removing material. The total mass of the workpiece remains the same.

Other examples include bending, rolling (used to make sheet metal and I-beams), and stamping.

Material Removal (Machining)

These are subtractive processes that start with a larger block of material (a billet or blank) and cut away unwanted portions to achieve the final shape. This is the opposite of forming.

Common examples are milling, turning (on a lathe), drilling, and grinding. They produce waste material, known as chips or swarf.

Additive Manufacturing

This is the newest category, where parts are built layer by layer from nothing. It is an "additive" process, the conceptual opposite of material removal.

The most well-known example is 3D printing, which can use polymers, metals, or composites.

How Forging Shapes and Strengthens Metal

Forging is unique among shaping processes because of how it improves the material itself. It is most often performed on metal that has been heated to make it more malleable.

The Principle of Plastic Deformation

Forging works by applying compressive force that exceeds the material's elastic limit, causing it to plastically deform—meaning it permanently takes on a new shape. This force can be delivered through a slow, steady squeeze (a press) or a rapid impact (a hammer).

The Critical Role of Grain Flow

The primary benefit of forging is its effect on the metal's internal grain structure. In a raw block of metal, the grains are typically random and non-uniform.

Forging forces these grains to deform and elongate, creating a continuous, unbroken grain flow that follows the contour of the part. This is analogous to the difference between a board cut from wood and a branch that has grown into a curve; the branch is far stronger because its fibers are continuous.

Superior Mechanical Properties

This refined grain structure is why forged components have exceptionally high strength, toughness, and fatigue resistance. The continuous grain flow helps distribute stress across the part, eliminating the internal weak points that can be present in cast or machined parts.

Understanding the Trade-offs

No single process is best for every application. Choosing forging involves considering its unique strengths and limitations compared to other methods.

Forging vs. Casting

Casting involves pouring molten metal into a mold. While casting can create highly complex shapes more easily and cheaply than forging, the resulting part has a random grain structure, making it more brittle and susceptible to porosity (tiny internal voids).

Forging is stronger; casting can be more complex. Forging is preferred for critical components like engine crankshafts, connecting rods, and aircraft landing gear where failure is not an option.

Forging vs. Machining

Machining from a solid bar can achieve very high precision and complex geometries. However, the cutting tool severs the material's natural grain structure, creating potential points of weakness. It also produces significant scrap material, which can be costly.

Often, the two processes are combined. A part is forged to a "near-net shape"—close to its final form—to establish the superior grain structure, and then finish-machined to achieve tight dimensional tolerances.

Key Limitations of Forging

The primary downside to forging is the high cost of the tooling. The hardened steel dies used to shape the metal are expensive to create and maintain. This makes forging most cost-effective for medium-to-high volume production runs where the tooling cost can be spread across thousands of parts.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on your project's specific requirements for performance, cost, and complexity.

- If your primary focus is maximum strength and fatigue resistance: Forging is the superior choice for creating robust, reliable parts that must withstand high stress.

- If your primary focus is intricate geometry or a one-off prototype: Machining from solid stock or 3D printing offers greater design freedom and lower setup costs for low volumes.

- If your primary focus is low unit cost for a complex shape in high volume: Casting is often the most economical path, provided the strength of a forged part is not required.

Understanding how each process fundamentally works empowers you to select the one that best aligns with your project's cost, performance, and volume requirements.

Summary Table:

| Aspect | Forging | Casting | Machining |

|---|---|---|---|

| Process Type | Forming/Shaping | Mold-Based | Material Removal |

| Material Strength | High (grain flow) | Moderate (random grain) | Varies (cut grain) |

| Complexity | Moderate | High | High |

| Best For | High-strength parts (e.g., crankshafts) | Complex shapes in volume | Precision, prototypes |

Need robust, high-strength components for your lab or industrial applications? KINTEK specializes in lab equipment and consumables, offering expertise in material shaping processes like forging to meet your demanding performance requirements. Contact us today to discuss how our solutions can enhance your project's durability and efficiency!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Small Injection Molding Machine for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- Why are hydraulic presses and pressure dies used for composite electrodes? Optimize Solid-State Battery Conductivity

- What type of machine is a hydraulic press? A Powerful Force Multiplier for Crushing, Molding, and Forging

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- How does a hydraulic press generate force? Unlocking the Power of Hydraulic Pressure

- How do a precision laboratory hydraulic press and specialized molds contribute to the fabrication of spherical ceramic samples? Achieving High-Density Material Precision

- How does a laboratory hydraulic press contribute to g-CNT electrode preparation? Mastering Material Densification

- What key role does a laboratory pellet press play in FTIR analysis? Master KBr Sample Preparation Excellence

- What is another name for a hydraulic press? The Bramah Press and Its Powerful Principle