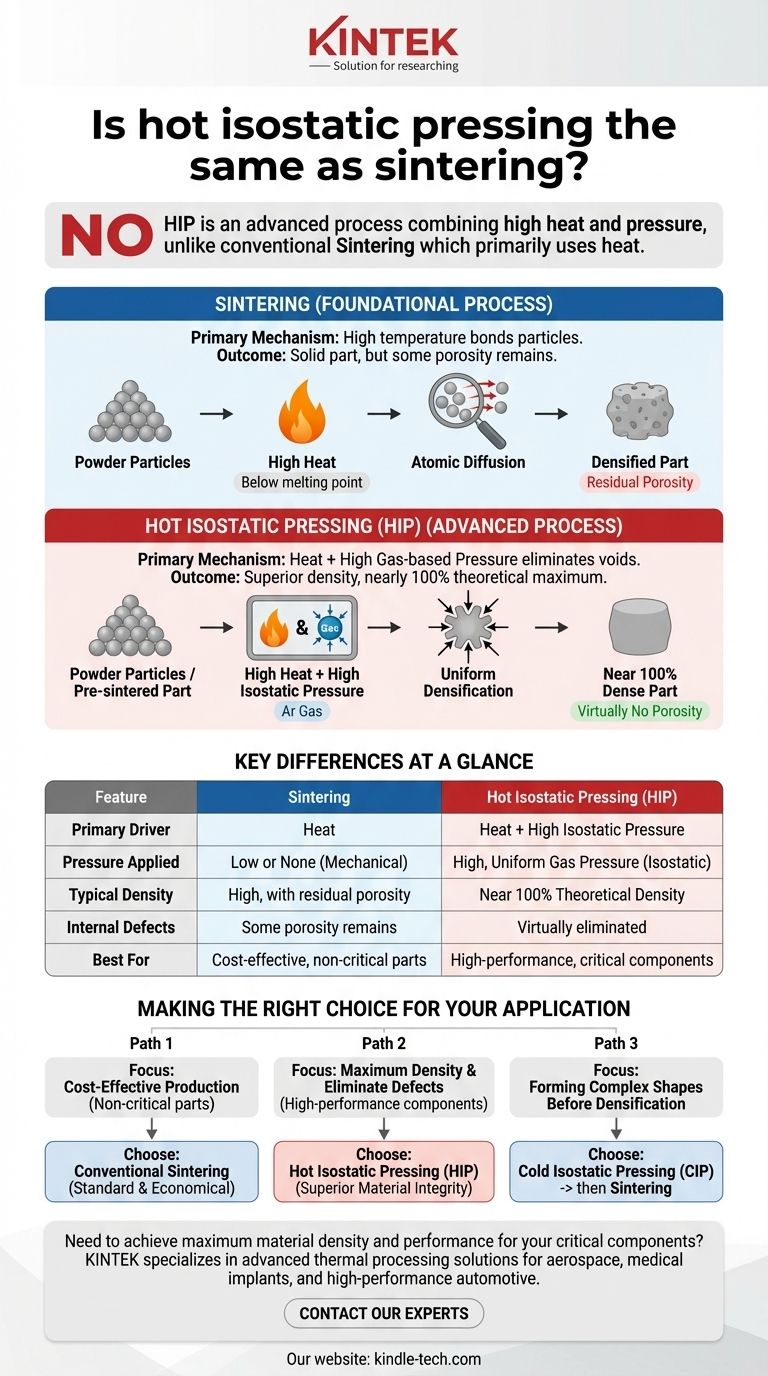

No, Hot Isostatic Pressing (HIP) is not the same as sintering, but it is a related and more advanced process. Sintering is the fundamental process of using high heat to bond powder particles into a solid mass. Hot Isostatic Pressing enhances this by simultaneously applying extremely high, uniform (isostatic) pressure, which results in a component with superior density and minimal internal defects.

While both processes use heat to create solid parts from powders, they are fundamentally different in their use of pressure. Sintering relies primarily on heat for densification, whereas Hot Isostatic Pressing combines heat with high, gas-based pressure to virtually eliminate all internal porosity.

What is Sintering? The Foundational Process

Sintering is a core technique in powder metallurgy, where loose powder is transformed into a coherent, solid object.

The Goal: Fusing Powder with Heat

The primary mechanism of sintering is high temperature, typically below the material's melting point. This thermal energy encourages the individual powder particles to bond together, forming a solid structure.

The Mechanism: Atomic Diffusion

At these elevated temperatures, atoms migrate across the boundaries of the particles. This movement systematically fills the gaps and voids between them, causing the material to shrink and increase in density.

The Outcome: A Densified Part

The result is a solid component with good mechanical properties. However, conventional sintering often leaves behind a small amount of residual porosity (tiny internal voids), which can limit the part's ultimate performance.

How Hot Isostatic Pressing (HIP) Elevates the Process

Hot Isostatic Pressing is a specialized manufacturing process that addresses the limitations of conventional sintering, particularly for high-performance applications.

The Key Ingredient: Isostatic Pressure

HIP adds a crucial element to the thermal process: high isostatic pressure. An inert gas, typically argon, is used to apply uniform pressure from all directions onto the part.

The Process in Practice

Components are loaded into a sealed, high-pressure vessel. The chamber is filled with inert gas, and then both temperature and pressure are increased according to a precisely controlled cycle. This combination forces the material to densify before it is carefully cooled and depressurized.

The Primary Advantage: Achieving Full Density

This combination of heat and high-pressure gas is extremely effective at closing and welding shut any internal voids or microporosity. The resulting product can achieve nearly 100% of its theoretical maximum density, leading to significantly improved mechanical properties like fatigue life and impact strength.

Key Differences at a Glance

While related, the two processes are distinct in their methods, applications, and outcomes.

Pressure: The Defining Factor

Sintering may occur with no external pressure or under low mechanical pressure. HIP is defined by its use of high-pressure inert gas to achieve uniform densification.

Application Scope

Sintering is a widely used powder metallurgy process for a vast range of parts. HIP is often used as a secondary step to densify conventionally sintered or cast components, or to fabricate advanced materials like metal matrix composites.

Precursor Processes

Sometimes, a part is first formed using Cold Isostatic Pressing (CIP), which uses liquid pressure at room temperature to create a "raw" or "green" part. This part has enough strength to be handled but must then be sintered to achieve its final density and strength. HIP, by contrast, accomplishes forming and full densification in a single thermal-mechanical cycle.

Understanding the Trade-offs

Choosing between these processes requires balancing performance requirements with economic realities.

Cost and Complexity

HIP equipment is significantly more complex and expensive to acquire and operate than standard sintering furnaces. The process requires careful control over extreme pressures and temperatures, adding to operational costs.

Performance vs. "Good Enough"

For critical applications in aerospace, medical implants, or high-performance automotive parts, the superior properties and reliability of a HIPed component justify the cost.

For many industrial and consumer goods, the properties achieved through conventional sintering are perfectly adequate. In these cases, it remains the more economical and practical choice.

Making the Right Choice for Your Application

Your final decision depends entirely on the performance, reliability, and cost requirements of your component.

- If your primary focus is cost-effective production of non-critical parts: Conventional sintering is the standard and most economical choice.

- If your primary focus is achieving maximum density and eliminating internal defects for high-performance components: Hot Isostatic Pressing is the superior method for unmatched material integrity.

- If your primary focus is forming a complex powder shape before final densification: Use Cold Isostatic Pressing (CIP) to create a "green" part, which is then densified in a separate sintering step.

Ultimately, understanding the interplay between heat, pressure, and cost is key to selecting the optimal manufacturing path for your material.

Summary Table:

| Feature | Sintering | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Primary Driver | Heat | Heat + High Isostatic Pressure |

| Pressure Applied | Low or None | High, Uniform Gas Pressure |

| Typical Density | High, but with residual porosity | Near 100% Theoretical Density |

| Internal Defects | Some porosity remains | Virtually eliminated |

| Best For | Cost-effective, non-critical parts | High-performance, critical components |

Need to achieve maximum material density and performance for your critical components?

KINTEK specializes in advanced thermal processing solutions, including lab equipment for sintering and HIP research. Whether you are developing materials for aerospace, medical implants, or high-performance automotive applications, our expertise can help you select the right process to eliminate internal defects and unlock superior mechanical properties.

Contact our experts today to discuss how we can support your laboratory's material development and processing needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- How do magnetic stirrers and vacuum drying ovens work together to optimize catalyst performance? Expert Prep Guide

- What is the internal storage volume range of Ultra Freezers? From 200L to 800L+ to Match Your Lab's Needs

- What are the emerging trends in ULT freezer technology? Boost Efficiency, Security & Sustainability

- Why is it necessary to use a high-precision mass flow controller (MFC) in CO2 reduction? Ensure Accurate SPCE Data

- Is torrefaction or pyrolysis for biomass? Choose the Right Thermal Process for Your Biomass Goals

- What is the composition of plastic pyrolysis product? A Breakdown of Oil, Gas, and Char Outputs

- What are the liquid products of pyrolysis? The Ultimate Guide to Bio-Oil Production

- What are the findings of peer-reviewed studies on storing microorganisms at -70°C? A Reliable Method for Long-Term Preservation