At its core, Hot Isostatic Pressing (HIP) is a materials engineering process that uses a combination of high temperature and uniform, high-pressure gas to improve a material's properties. It functions by applying this pressure equally from all directions (isostatically) to collapse and eliminate internal voids, porosity, and microscopic defects within a solid part or a compacted powder.

The crucial insight is that HIP is not simply a forming process; it is a healing process. It fundamentally re-engineers a material from the inside out, removing hidden flaws to achieve a level of density and structural integrity that is often unattainable through other manufacturing methods.

How the HIP Process Fundamentally Works

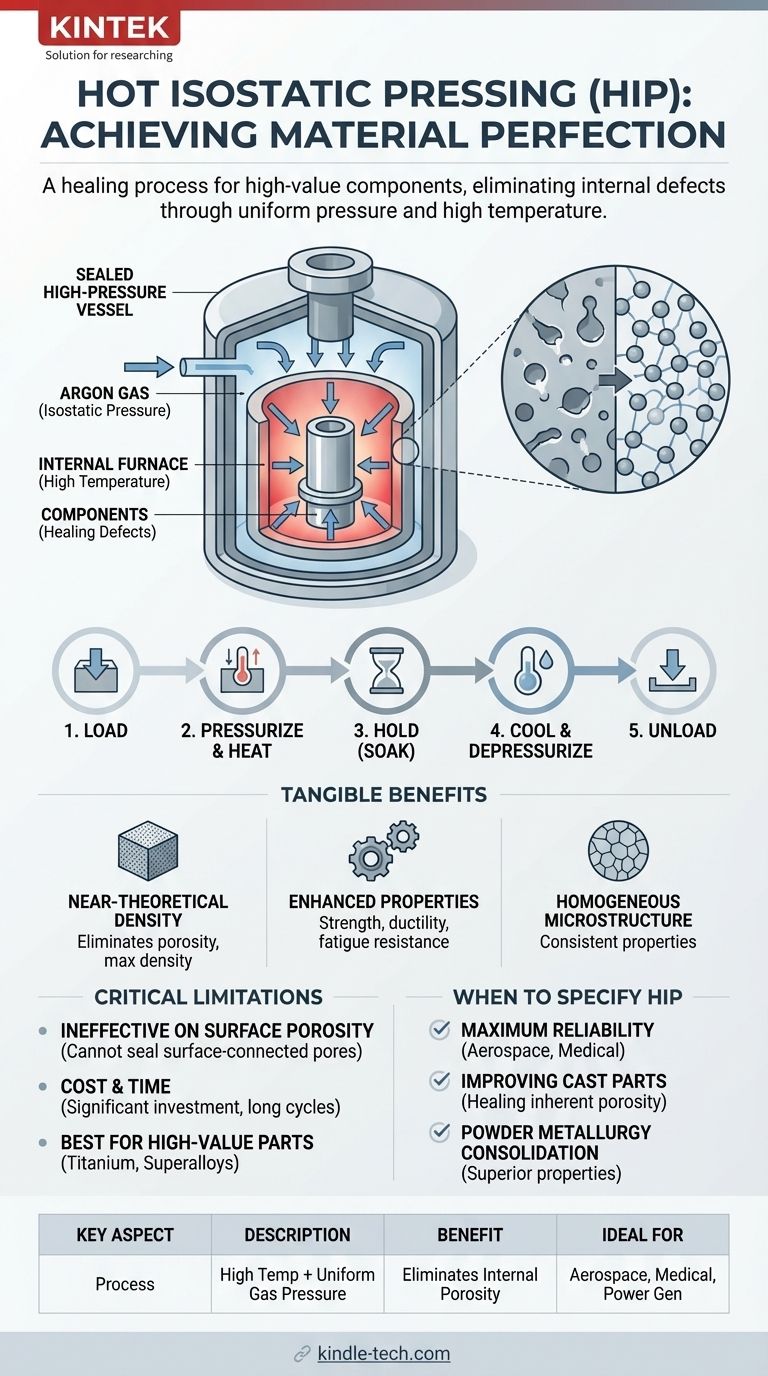

To understand the value of HIP, it's essential to grasp the principles behind its operation. The process takes place entirely within a sealed, high-pressure vessel containing a specialized furnace.

The Principle of Isostatic Pressure

The "isostatic" part is key. Unlike a mechanical press that applies force from one or two directions, HIP uses a pressurized inert gas, typically argon, to exert uniform pressure on the component from every conceivable angle.

Think of it like submerging an object deep in the ocean. The water pressure is equal on all surfaces. This ensures that internal voids are closed without distorting the part's overall shape.

The Role of High Temperature

Pressure alone is not enough. The high temperature, controlled by the internal furnace, brings the material to a state where it becomes soft and malleable, well below its melting point.

This elevated temperature allows the atoms within the material to move, a process known as diffusion. It makes the material plastic enough for the immense external pressure to effectively collapse any internal gaps.

The Step-by-Step Cycle

A typical HIP cycle follows a precise and controlled sequence:

- Load: Components are loaded into the furnace, which is then placed inside the pressure vessel.

- Pressurize and Heat: The vessel is sealed, and inert gas is pumped in as the furnace heats up. Pressure and temperature rise simultaneously.

- Hold (Soak): The vessel is held at a specific target temperature and pressure for a set duration, often lasting several hours. During this phase, internal voids collapse and the surfaces diffusion bond, healing the defects.

- Cool and Depressurize: The components are cooled within the vessel. This can sometimes be a rapid cooling phase to act as a quenching heat treatment. Afterwards, the gas is released, often to be cleaned and recycled.

- Unload: The furnace is removed from the vessel, and the densified, strengthened components are unloaded.

The Tangible Benefits of HIP Treatment

Applying this process yields significant and measurable improvements in material quality, directly impacting performance and reliability.

Achieving Near-Theoretical Density

The primary goal and result of HIP is the elimination of internal porosity. This allows the material to achieve nearly 100% of its theoretical maximum density, which is critical for high-performance applications.

Enhanced Mechanical Properties

By removing microscopic defects that act as stress concentration points, HIP dramatically improves a material's mechanical properties. This includes increases in strength, ductility, fatigue resistance, and overall durability.

Creating Homogeneous Microstructures

The process is particularly effective in powder metallurgy, where it transforms compacted metal powders into a fully dense solid. It creates a fine-grained, uniform (homogeneous) microstructure, ensuring that material properties are consistent and predictable throughout the entire part.

Understanding the Critical Limitations

While powerful, HIP is not a universal solution. Understanding its trade-offs is crucial for making informed engineering decisions.

Ineffectiveness on Surface Porosity

HIP can only eliminate internal, sealed-off voids. It cannot fix porosity that is connected to the surface of the part.

The reason is simple: the pressurized gas fills the surface-connected pore, creating an equal pressure inside and outside the defect. With no pressure differential, there is no force to collapse it.

Material and Application Suitability

While the process can be applied to nearly any material, its cost and long cycle times (often 8-12 hours) make it most suitable for high-value components. It is commonly used for materials that are difficult to cast without defects, such as titanium alloys, superalloys, and stainless steels.

Process Cost

HIP equipment is a significant capital investment, and the long cycle times make it a relatively expensive batch process. It is therefore reserved for applications where the enhanced performance and reliability justify the added cost.

When to Specify Hot Isostatic Pressing

Your decision to use HIP should be directly tied to the final performance requirements of your component.

- If your primary focus is maximum reliability in critical components: Use HIP to eliminate hidden internal defects in parts for aerospace, medical implants, or power generation where failure is not an option.

- If your primary focus is improving the properties of cast parts: Apply HIP as a secondary step to heal the inherent porosity in complex castings, dramatically increasing their strength and fatigue life.

- If your primary focus is creating fully dense parts from metal powders: Specify HIP as the consolidation method in your powder metallurgy process to achieve properties superior to those from casting or forging.

Ultimately, Hot Isostatic Pressing is the definitive tool for achieving material perfection when performance and reliability cannot be compromised.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | High temperature + uniform gas pressure applied from all directions. |

| Primary Benefit | Eliminates internal porosity, achieving near-theoretical density. |

| Key Improvements | Enhanced strength, ductility, fatigue resistance, and durability. |

| Ideal For | High-value components in aerospace, medical, and power generation. |

| Limitation | Cannot fix surface-connected porosity. |

Ready to eliminate internal defects and achieve material perfection in your components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing (HIP), to help you enhance the reliability and performance of your critical parts. Whether you are working with titanium alloys, superalloys, or complex castings, our expertise ensures your materials meet the highest standards for demanding applications in aerospace, medical, and energy sectors.

Contact our experts today to discuss how HIP can transform your material properties and ensure failure is not an option for your components.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How long does hot isostatic pressing take? From Hours to Days, Unpacking the Full HIP Cycle

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What is the working principle of hot isostatic pressing? Unlock Superior Material Density & Performance

- What is the HIP process of casting? Transform Castings into High-Performance Components

- Why is Hot Isostatic Pressing (HIP) Required for Additive Inconel 718? Achieve 100% Theoretical Density

- What are the disadvantages of hot isostatic pressing? The High Cost of Superior Material Performance

- What is the temperature and pressure for hot isostatic pressing? Achieve 100% Dense, High-Performance Materials

- What is the function of a Warm Isostatic Press (WIP) in all-solid-state pouch cells? Optimize Battery Density