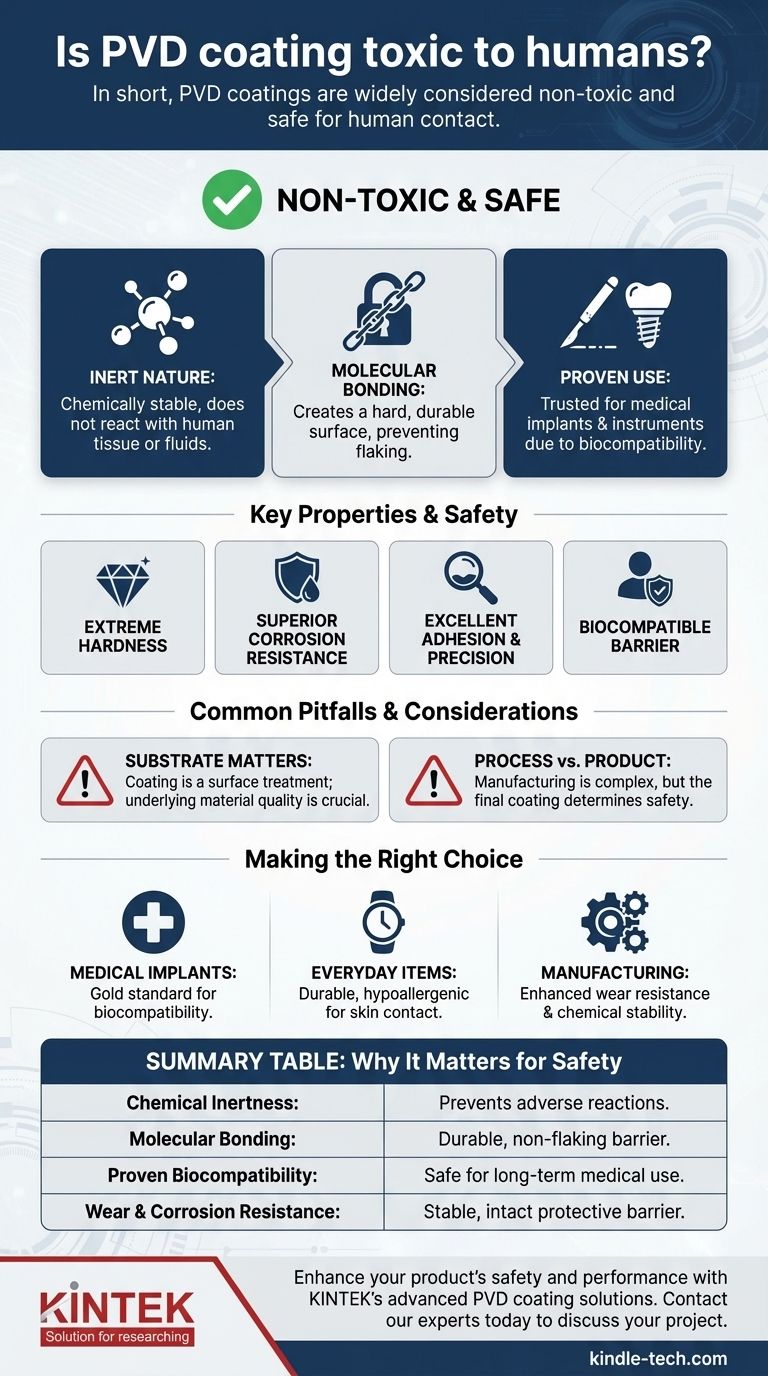

In short, PVD coatings are widely considered non-toxic and safe for human contact. These coatings are fundamentally biocompatible and inert, meaning they do not react with human tissue or bodily fluids. This exceptional stability is precisely why PVD is a trusted coating for medical implants, surgical instruments, and other sensitive applications.

The core reason PVD coatings are safe is that the process creates a molecularly-bonded, chemically stable surface. This ceramic-like layer acts as an inert barrier, preventing the base metal from interacting with the human body.

What Makes PVD Coatings Biocompatible?

The safety of PVD (Physical Vapor Deposition) coatings isn't an accident; it's a result of the material's fundamental chemical and physical properties.

The Inert Nature of the Coating

PVD coatings are chemically inert. They are engineered to be highly resistant to corrosion and oxidation.

This means they do not break down or release particles when exposed to moisture, salts, or acids from the human body. This stability prevents any adverse reactions with bones, tissues, or fluids.

Molecular Bonding and Durability

Unlike a layer of paint, a PVD coating is not simply applied to a surface; it is bonded at a molecular level within a vacuum chamber.

This creates an extremely hard and durable finish that is highly resistant to wear, scratches, and flaking. Because the coating stays intact, there is no mechanism for it to enter the body.

Proven Use in Sensitive Applications

The most compelling evidence for the safety of PVD is its extensive use in the medical field.

Surgeons rely on PVD-coated instruments, and these same coatings are used on medical implants designed for long-term placement inside the human body, demonstrating a high degree of trust in their biocompatibility.

Understanding the Key Properties

Several key characteristics of PVD coatings contribute directly to both their performance and their safety profile.

Extreme Hardness and Wear Resistance

PVD coatings significantly increase the surface hardness of an object. This makes products like watches, jewelry, and fixtures exceptionally resistant to daily wear.

This durability is a safety feature: a coating that doesn't scratch or chip is a coating that remains a stable, protective barrier.

Superior Corrosion Resistance

The coating seals the underlying substrate material (often stainless steel) from the environment.

This prevents the base metal from oxidizing or corroding, which could otherwise release potentially irritating metal ions, such as nickel.

Excellent Adhesion and Precision

The PVD process results in a very thin layer—typically 0.5 to 5 microns—that adheres perfectly to the substrate.

It maintains the precise dimensions and even the texture of the original surface, ensuring that a product's form and function are not compromised while its safety and durability are enhanced.

Common Pitfalls and Considerations

While the final PVD coating is inert and safe, it is important to understand the full context of the technology.

The Substrate Material Still Matters

The PVD coating is a surface treatment. While it provides an inert barrier, the overall quality and safety of the product also depend on the underlying material.

A high-quality, biocompatible coating applied over a poor-quality or reactive base metal is not a suitable combination for sensitive applications. The properties of the final product are a result of both the coating and the substrate.

The Process vs. The Final Product

The PVD application process itself is complex, requiring specialized vacuum chambers and technical expertise.

These manufacturing considerations, however, are distinct from the properties of the finished product. For the end-user, the final, stable coating is what determines safety.

Making the Right Choice for Your Goal

Your confidence in a PVD-coated product should be based on its intended use.

- If your primary focus is medical implants or tools: PVD is a gold standard, chosen specifically for its proven biocompatibility and inertness inside the body.

- If your primary focus is everyday items (jewelry, watches, fixtures): The PVD finish provides a highly durable, hypoallergenic, and safe barrier ideal for direct skin contact.

- If your primary focus is manufacturing: Specifying a PVD coating ensures a part will have enhanced wear resistance, durability, and chemical stability, improving its lifelong performance.

Ultimately, PVD technology provides a robust and reliable way to create surfaces that are as safe as they are durable.

Summary Table:

| Property | Why It Matters for Safety |

|---|---|

| Chemical Inertness | Does not react with bodily fluids or tissues, preventing adverse reactions. |

| Molecular Bonding | Creates a durable, non-flaking barrier that prevents particles from entering the body. |

| Proven Biocompatibility | Extensively used in medical implants and surgical instruments for long-term safety. |

| Wear & Corrosion Resistance | A stable, scratch-resistant surface ensures the protective barrier remains intact. |

Enhance your product's safety and performance with KINTEK's advanced PVD coating solutions.

Whether you are developing medical devices, durable consumer goods, or specialized industrial components, our expertise in lab equipment and consumables ensures you achieve a perfectly biocompatible and durable finish. We provide the technology and support to create surfaces that are trusted for direct human contact.

Contact our experts today to discuss how our PVD solutions can bring safety and durability to your next project.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance