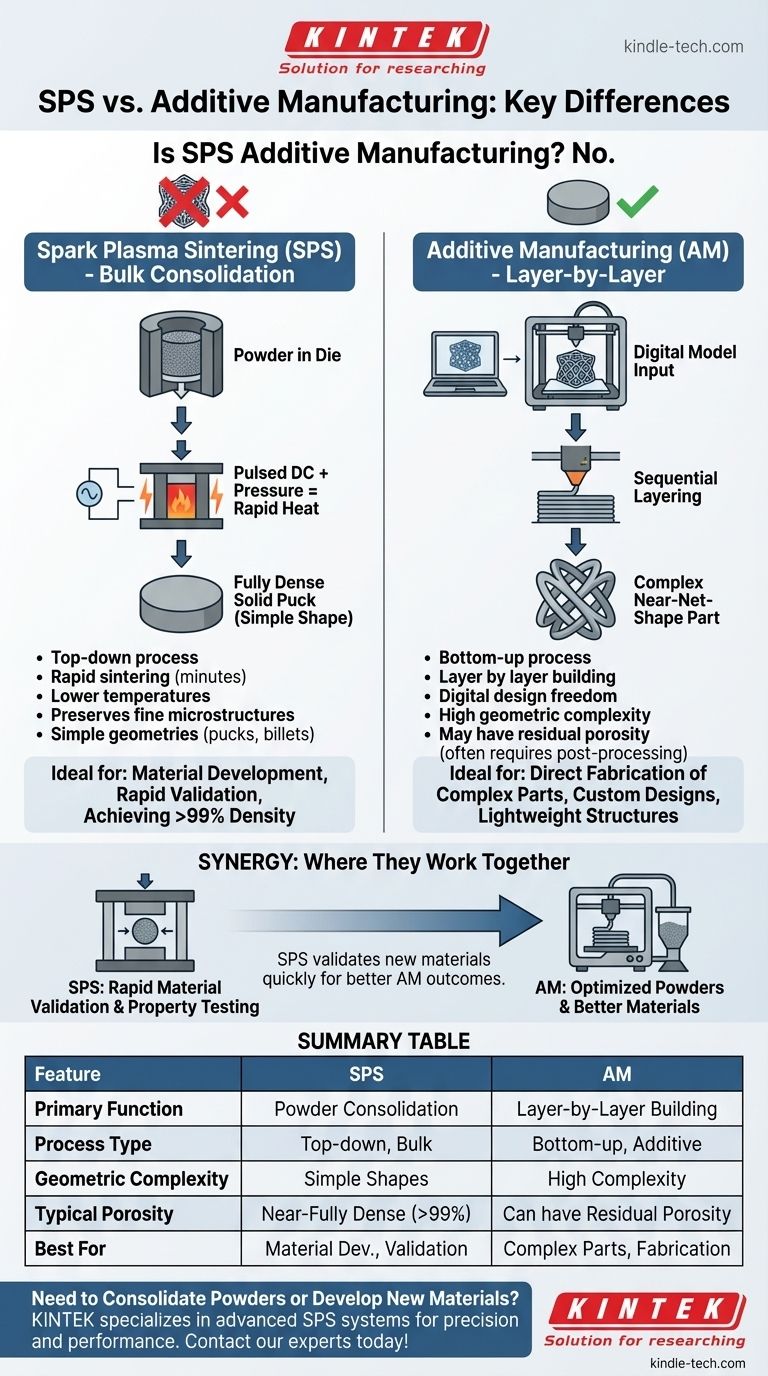

In short, no. Spark Plasma Sintering (SPS) is not considered an additive manufacturing (AM) process. While both technologies often start with powdered materials, they operate on fundamentally different principles. SPS is a powder metallurgy consolidation technique, whereas additive manufacturing builds parts layer by additive layer.

Additive manufacturing, like 3D printing, constructs a part from the ground up, layer by layer. In contrast, Spark Plasma Sintering is a bulk consolidation process that uses heat and pressure to transform a volume of powder into a dense, solid material all at once.

What is Spark Plasma Sintering?

A High-Speed Consolidation Process

Spark Plasma Sintering, also known as Field Assisted Sintering Technology (FAST), is a technique used to densify powders into a solid mass. It works by loading the powder into a graphite die.

A powerful pulsed Direct Current (DC) is then passed through the die and the powder, while mechanical pressure is simultaneously applied. This combination generates rapid, intense heating directly within the material.

The Core Mechanism

This unique heating method allows for extremely fast sintering cycles—often just a few minutes—at lower temperatures than conventional furnace sintering. This rapid process is crucial for preserving fine-grained microstructures and creating materials with superior properties.

Think of it like a highly advanced, ultra-fast panini press. Instead of bread, you have powder, and instead of just heat, you use a combination of electrical current and immense pressure to fuse it into a solid hockey puck-like shape.

How SPS Differs from Additive Manufacturing

Method of Part Creation

The most significant difference is the manufacturing approach. Additive Manufacturing is a "bottom-up" process that builds a part's geometry sequentially, one thin layer at a time, based on a digital model.

Spark Plasma Sintering is a "top-down" consolidation. It takes a pre-measured quantity of powder and converts the entire volume into a solid, simple shape (like a cylinder or disc) in a single step.

Geometric Complexity

Additive manufacturing excels at producing highly complex, intricate, and near-net-shape parts directly from a CAD file. This is its primary advantage.

SPS, by contrast, produces very simple geometric forms. The final shape is dictated by the shape of the die. These simple forms, often called "pucks" or "billets," usually require significant secondary machining to become a functional component.

Material Properties and Porosity

SPS is renowned for its ability to produce materials that are near-fully dense (over 99% theoretical density). The combination of pressure and rapid heating is highly effective at eliminating voids between powder particles.

While additive manufacturing technologies have improved, parts produced by AM—especially metal AM—can sometimes suffer from residual porosity, which can compromise mechanical performance. Achieving full density often requires post-processing steps like Hot Isostatic Pressing (HIP).

The Synergy: Where SPS and AM Work Together

Despite their differences, SPS and additive manufacturing are not rivals; they are often complementary tools, especially in materials research and development.

Rapid Material Validation

Imagine you've developed a novel metal alloy powder intended for a powder-bed fusion AM process. Before committing to a complex and expensive AM build, you need to understand the material's fundamental properties when fully dense.

SPS is the perfect tool for this. Researchers can take a small amount of the new powder, use SPS to rapidly create a fully dense sample, and then test its hardness, strength, and other characteristics. This provides a critical performance baseline for the material itself.

A Pathway to Better AM Materials

By using SPS to quickly iterate and test different powder compositions, materials scientists can develop and optimize new alloys much faster. These validated powders can then be used to feed advanced additive manufacturing systems.

Understanding the Trade-offs of SPS

Severe Geometric Limitations

The most obvious limitation is the inability to create complex shapes. SPS is not a tool for direct part fabrication; it's a tool for creating bulk material samples or simple preforms.

Size and Scale Constraints

The size of the part you can create is limited by the size of the press and the graphite die tooling. While large-scale SPS systems exist, they are far less common and more expensive.

Specialized and Expensive Equipment

SPS systems are highly specialized pieces of laboratory or industrial equipment. They represent a significant capital investment and require trained operators, placing them in a different category from many more accessible desktop or benchtop AM systems.

Making the Right Choice for Your Goal

If your primary focus is creating a geometrically complex, near-net-shape part: You need additive manufacturing. Its ability to build directly from a digital file is unmatched for this purpose.

If your primary focus is producing a fully dense, high-performance bulk material from a powder: Spark Plasma Sintering is the superior choice for achieving maximum density and fine-grained microstructures quickly.

If your primary focus is developing and qualifying new powders for manufacturing: Use SPS as a rapid validation tool to understand the ideal properties of your material before attempting to use it in an AM process.

Ultimately, understanding the distinct roles of these technologies empowers you to select the right tool for the job.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Additive Manufacturing (AM) |

|---|---|---|

| Primary Function | Powder consolidation into dense solids | Layer-by-layer part building |

| Process Type | Top-down, bulk consolidation | Bottom-up, additive layering |

| Geometric Complexity | Simple shapes (e.g., discs, cylinders) | High complexity, near-net-shape |

| Typical Porosity | Near-fully dense (>99%) | Can have residual porosity |

| Best For | Material development, rapid validation | Direct fabrication of complex parts |

Need to Consolidate Powders or Develop New Materials?

KINTEK specializes in advanced laboratory equipment, including Spark Plasma Sintering systems. Whether your goal is rapid material validation, producing fully dense samples, or optimizing powders for additive manufacturing, our solutions deliver the precision and performance you need.

Contact our experts today to discuss how SPS can accelerate your R&D and material science projects.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What are the advantages of SPS? Achieve Superior Material Density and Performance