Yes, sputtering is a deposition process that is fundamentally dependent on a vacuum. However, the role of the vacuum is more nuanced than simply removing air. The process begins by creating a high vacuum to ensure a pristine environment, after which a specific, low-pressure sputtering gas is introduced to enable the actual deposition.

The core purpose of the vacuum in sputtering is twofold: first, to create an ultra-clean, contaminant-free environment for the substrate and target, and second, to provide a controlled, low-pressure atmosphere of a specific gas that can be ionized to perform the sputtering.

The Dual Role of the Vacuum in Sputtering

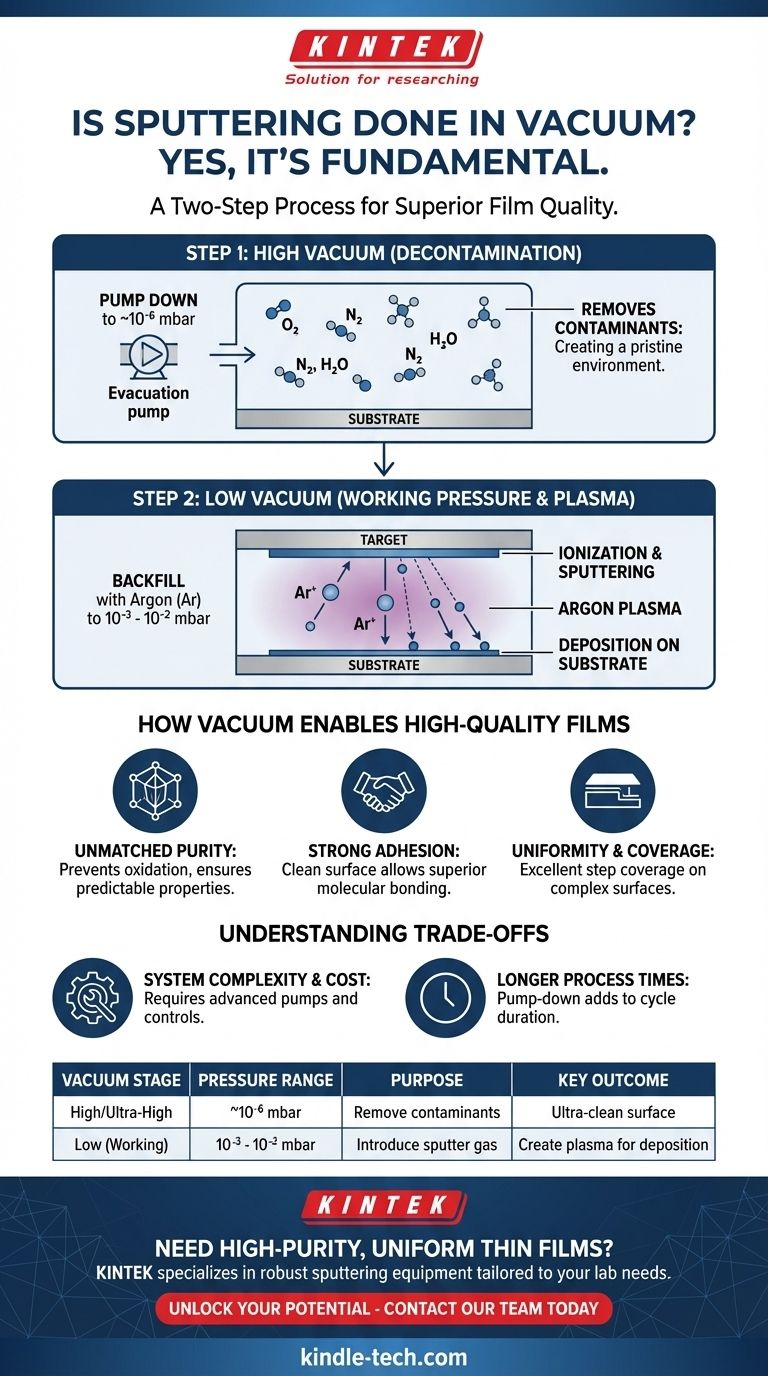

Understanding sputtering requires seeing the vacuum not as a single state, but as a critical part of a two-step process. Each step uses a different level of vacuum for a specific reason.

Step 1: Achieving an Ultra-Clean Environment

Before any deposition can occur, the chamber is pumped down to a high-vacuum or ultra-high-vacuum state, typically around 10⁻⁶ mbar or lower.

The goal here is decontamination. This process removes active atmospheric gases like oxygen, nitrogen, and water vapor that would otherwise interfere with the deposition, cause impurities, or form unwanted chemical compounds in the final film.

Think of this as meticulously cleaning and priming a surface before painting. Without this step, the deposited film would have poor quality and would not adhere properly to the substrate.

Step 2: Creating a Controlled Process Atmosphere

Once the chamber is clean, it is backfilled with a high-purity, inert sputter gas, most commonly Argon.

This raises the pressure slightly into the low-vacuum range, typically between 10⁻³ and 10⁻² mbar. This is the "working pressure."

This controlled gas atmosphere is essential because it is the medium that enables the process. A high voltage is applied, which ionizes the sputter gas atoms, turning them into a plasma. These ions are then accelerated into the target material, dislodging atoms that then travel to and coat the substrate.

How the Vacuum Enables High-Quality Films

The careful management of the vacuum environment is directly responsible for the key advantages of sputtering as a thin-film deposition technique.

Ensuring Unmatched Purity

By first removing virtually all other gases, the process ensures that the only atoms interacting with the target and substrate are those from the inert sputter gas and the target material itself. This prevents oxidation and other contamination, leading to highly pure films with predictable properties.

Promoting Strong Adhesion

The initial high-vacuum stage effectively "scrubs" the substrate surface on a molecular level. When the sputtered atoms arrive, they land on a perfectly clean surface, allowing for the formation of a much stronger, more durable bond than is possible with non-vacuum methods.

Enabling Uniformity and Coverage

The low-pressure working atmosphere provides a long "mean free path" for the sputtered atoms. This means they can travel from the target to the substrate with fewer collisions, leading to highly uniform coatings. This environment also allows for excellent step coverage, where the film can uniformly coat complex, non-flat surfaces.

Understanding the Trade-offs

While powerful, the reliance on a sophisticated vacuum system introduces specific challenges and limitations.

System Complexity and Cost

Sputtering systems are more complex than other deposition techniques like thermal evaporation. Achieving and controlling both high- and low-vacuum states requires advanced turbomolecular or cryogenic pumps, precise gas flow controllers, and sophisticated gauges, which increases equipment cost and maintenance requirements.

Longer Process Times

The time required to pump the chamber down to a high vacuum before each run, known as the "pump-down time," adds to the total process cycle. This can make sputtering a slower method compared to techniques with less stringent vacuum requirements. The trade-off is higher quality and reproducibility for lower throughput.

Making the Right Choice for Your Goal

The vacuum process is what makes sputtering a high-performance technique. Use this knowledge to decide if it aligns with your project's needs.

- If your primary focus is film purity, density, and specific stoichiometry: Sputtering is ideal because the vacuum process removes reactive contaminants that cause defects and alter material properties.

- If your primary focus is strong adhesion to the substrate: The ultra-clean surface prepared in the high-vacuum stage ensures superior bonding for durable and reliable coatings.

- If your primary focus is coating complex shapes or achieving high uniformity: The controlled low-pressure environment in sputtering provides excellent film thickness uniformity and step coverage.

- If your primary focus is rapid, low-cost deposition of simple materials: You might consider alternatives like thermal evaporation, which have simpler vacuum needs and faster rates but offer less control over film quality and structure.

Ultimately, sputtering is the definitive choice when the precision, purity, and integrity of the thin film are more critical than raw deposition speed.

Summary Table:

| Vacuum Stage | Pressure Range | Purpose | Key Outcome |

|---|---|---|---|

| High/Ultra-High Vacuum | ~10⁻⁶ mbar or lower | Remove contaminants (O₂, N₂, H₂O) | Ultra-clean substrate & target surface |

| Low Vacuum (Working Pressure) | 10⁻³ to 10⁻² mbar | Introduce inert sputter gas (e.g., Argon) | Create plasma for controlled atom deposition |

Need high-purity, uniform thin films for your research or production?

The controlled vacuum environment is the key to achieving the superior film quality, strong adhesion, and precise stoichiometry that sputtering offers. At KINTEK, we specialize in providing robust sputtering equipment and consumables tailored to your specific laboratory needs.

Let our experts help you unlock the full potential of your thin-film applications.

Contact our team today to discuss how our solutions can enhance your deposition process and ensure reliable, reproducible results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- How accurate is the XRF analyzer? Achieve Lab-Quality Results in the Field

- Is pyrolysis of plastic harmful? The Truth About Toxic Byproducts and Environmental Risks

- Which of the following property is affected by heat treatment? A Guide to Tailoring Material Performance

- How do the 3 types of thermal treatment differ? Master Annealing, Normalizing, and Hardening

- Why magnets are placed behind the target in sputtering? To Trap Electrons for Faster, Purer Coatings

- How does Rotavapor work? Master Gentle, Low-Temperature Solvent Evaporation

- What are the hazards of CNT? Understanding the Physical Risks of Carbon Nanotubes

- What is the yield of pyrolysis gas? A Guide to Controlling Your Output (20-35%)