In short, yes, modern XRF analyzers are safe. These instruments are designed with multiple layers of protection, and when operated by a trained user according to established safety protocols, the radiation risk is negligible. The safety of an XRF analyzer is less about the technology itself and more about the procedures and training surrounding its use.

The core principle to understand is that XRF analyzers are not inherently dangerous in the way radioactive materials are. The risk is not from passive exposure but is strictly limited to the highly-directional, low-power X-ray beam, which is only active for a few seconds during a test and is controlled by multiple safety interlocks.

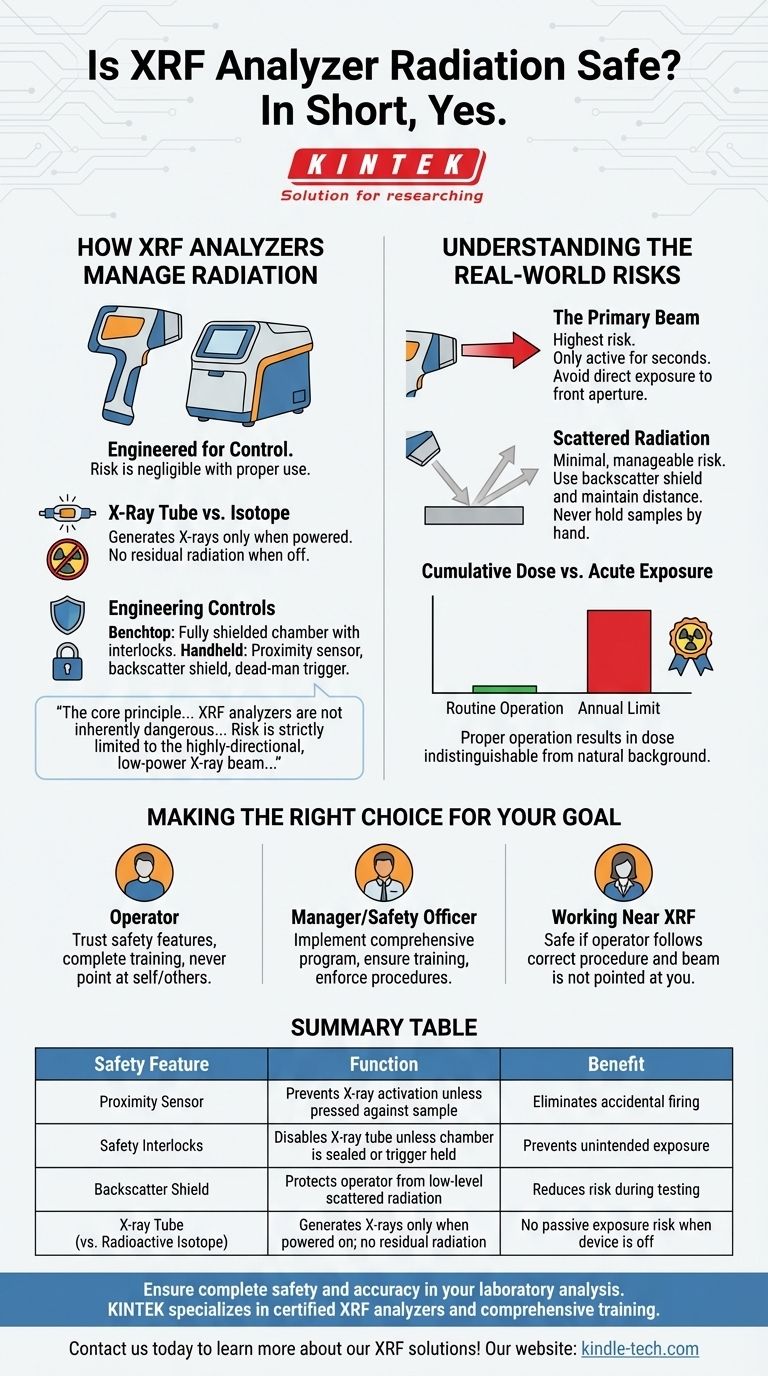

How XRF Analyzers Manage Radiation

To understand why these devices are safe, you must first understand how they are engineered to control and contain the X-ray source. The risk is managed through a combination of low-energy physics and robust engineering controls.

The Nature of XRF Radiation

An XRF analyzer uses an electrically powered X-ray tube to generate a beam of X-rays. This is fundamentally different from devices that use a constantly decaying radioactive isotope.

When the analyzer is powered off, no radiation is produced. The radiation generated is also relatively low-energy, designed only to excite atoms in a sample, not to penetrate deeply into materials or tissue.

Engineering Controls in Benchtop Analyzers

Desktop and benchtop XRF systems are the safest configuration. They are designed as fully enclosed, radiation-shielded chambers.

These systems use safety interlocks that make it physically impossible to activate the X-ray tube unless the chamber lid is closed and sealed. The unit's housing provides all the necessary shielding, reducing the external radiation level to near background levels.

Safety Features in Handheld Analyzers

Handheld units require more operator awareness, so they are equipped with multiple safety features to prevent accidental exposure.

Modern handheld analyzers feature a proximity sensor on the nose of the device. The analyzer will not generate X-rays unless this sensor is pressed firmly against the sample surface, preventing it from being fired into open air.

They also incorporate a backscatter shield to protect the operator's hands and body from low-level radiation that scatters off the sample surface during a test. Finally, a "dead-man" trigger ensures the beam stops the instant the operator releases the trigger.

Understanding the Real-World Risks

While engineered to be safe, it's critical to understand the specific nature of the remaining risks, all of which are related to improper use.

The Primary Beam: The Zone of Highest Risk

The only significant hazard from an XRF analyzer is direct exposure to the primary beam. This beam is highly focused and exits only from the front aperture (the "nose") of the analyzer.

Direct exposure, caused by intentionally defeating safety features and pointing the unit at a body part, would result in a localized radiation dose. The primary danger here is not long-term cancer risk but a severe, burn-like injury to the skin and underlying tissue.

Scattered Radiation: A Minimal but Manageable Risk

When the primary beam hits a sample, some X-rays scatter in various directions. This scattered radiation is much weaker than the primary beam.

This is why operators are trained never to hold a sample in their hand during a test. The backscatter shield and maintaining proper distance effectively mitigate this minor risk.

Cumulative Dose vs. Acute Exposure

Regulatory bodies set strict annual limits for occupational radiation exposure. When using XRF analyzers correctly, an operator's cumulative dose remains far below these limits.

Routine dosimetry (the use of radiation monitoring badges) confirms that proper operating procedures result in a dose that is often indistinguishable from natural background radiation.

Common Pitfalls and Misconceptions

Building trust in the technology means being clear about what not to do. Nearly all XRF-related incidents are due to human error, not equipment failure.

The Myth of "Leaking" Radiation

A common fear is that the device "leaks" radiation or makes the tested sample radioactive. Both are false. The X-rays stop the moment the power is cut, and the process of X-ray fluorescence does not leave any residual radioactivity in the sample.

The Danger of Defeating Safety Interlocks

The single greatest risk is the intentional bypass of safety features. An operator who, for example, tapes down a proximity sensor to test samples from a distance is creating an unacceptable hazard where none previously existed.

Inadequate Training and Complacency

Proper, certified training is not a suggestion; it is a requirement. Complacency is the enemy of safety. Operators who forget their training and take shortcuts, like holding small samples by hand, are the most likely to cause an incident.

Making the Right Choice for Your Goal

Your approach to XRF safety depends on your role. Following the correct procedures eliminates the risk and empowers you to use this powerful technology with confidence.

- If you are an operator: Your priority is to trust the device's safety features, complete all required training, and never point the analyzer at yourself or anyone else.

- If you are a manager or safety officer: Your responsibility is to implement a comprehensive radiation safety program, ensure all users are trained and certified, and enforce procedures without exception.

- If you simply work near an XRF analyzer: You can be confident that you are not exposed to radiation as long as the operator is following correct procedure and the beam is not pointed at you.

Ultimately, a properly used XRF analyzer is a safe and indispensable tool, and your knowledge of its safety systems is the key to its effective use.

Summary Table:

| Safety Feature | Function | Benefit |

|---|---|---|

| Proximity Sensor | Prevents X-ray activation unless pressed against a sample | Eliminates accidental firing into open air |

| Safety Interlocks | Disables X-ray tube unless chamber is sealed (benchtop) or trigger is held (handheld) | Prevents unintended exposure |

| Backscatter Shield | Protects operator from low-level scattered radiation | Reduces risk during sample testing |

| X-ray Tube (vs. Radioactive Isotope) | Generates X-rays only when powered on; no residual radiation | No passive exposure risk when device is off |

Ensure complete safety and accuracy in your laboratory analysis. KINTEK specializes in providing advanced, safety-certified XRF analyzers and comprehensive operator training. Our lab equipment and consumables are designed to meet the highest safety standards while delivering precise results for your laboratory needs.

Contact us today to learn more about our XRF solutions and how we can support your lab's safety and efficiency goals!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- Is biomass the best renewable energy source? Weighing Reliability Against Environmental Impact

- What is the effect of density on sintering? Achieve Superior Quality and Dimensional Accuracy

- How do industrial-grade constant temperature drying ovens ensure GO anti-corrosion coating performance?

- What type of wastes are used for the pyrolysis treatment? Unlock Value from Organic Waste Streams

- What is the difference between DC sputtering and RF sputtering? Choose the Right Technique for Your Material

- How are carbon nanotubes synthesized by laser evaporation? Unlocking High-Purity SWCNTs for Advanced Tech

- What happens during sintering? Transform Powder into Dense, Strong Components

- How do high-precision high-pressure injection pumps contribute to flow-through reactor systems? Expert Insights